Method for preparing graphene polyvinyl chloride resin compound material

A technology of resin composite material and vinyl polyvinyl chloride, which is applied in the field of preparation of graphene polyvinyl chloride resin composite material, can solve problems such as modification difficulties, and achieves improved tensile strength and wear resistance, improved dispersibility, and improved The effect of compounding properties

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

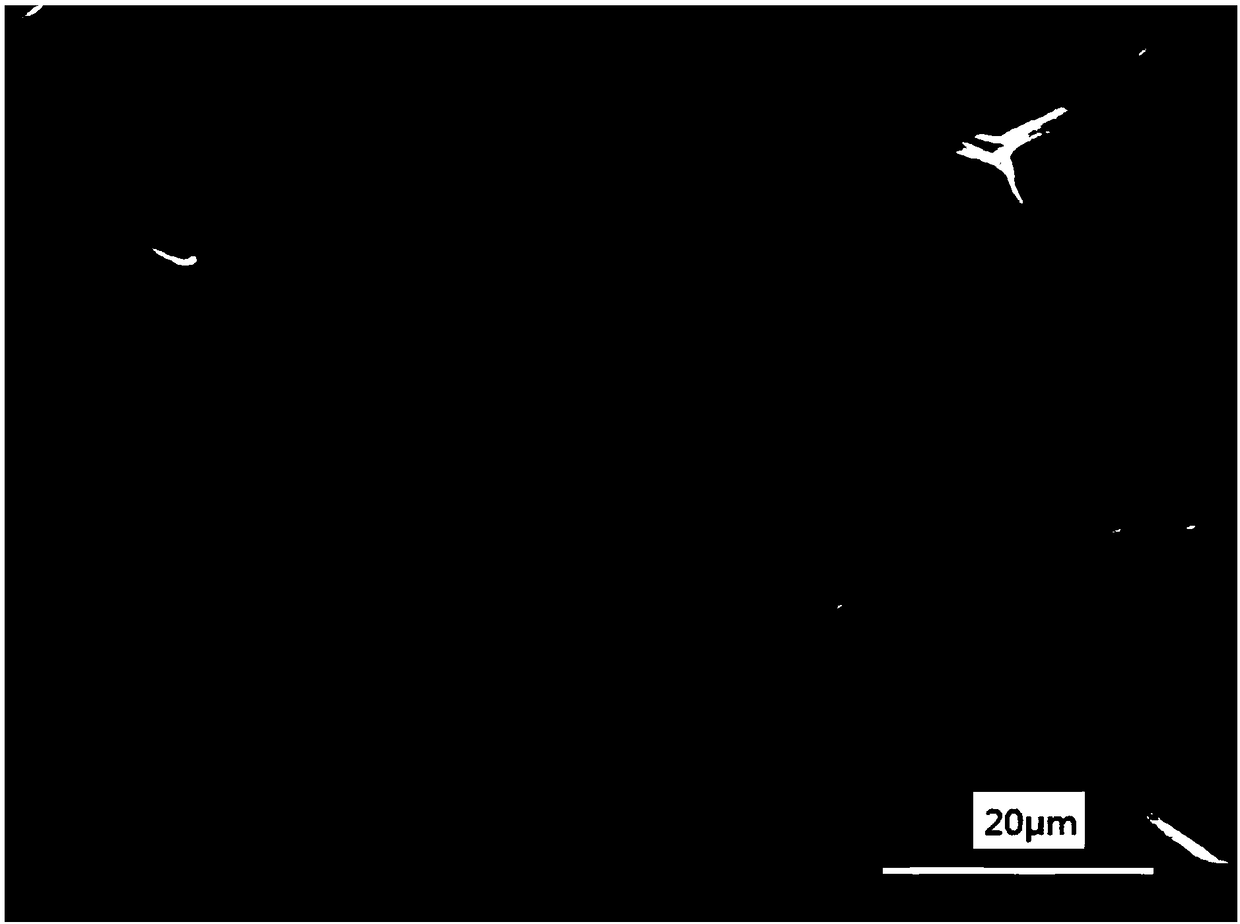

Image

Examples

Embodiment 1

[0019] A kind of preparation method of graphene polyvinyl chloride resin composite material, comprises the following steps:

[0020] Step 1, the preparation of graphite oxide: (1) measure the concentrated sulfuric acid of the massfraction 98% of 115ml and add in the beaker, cool in the ice-water bath; Slowly add 15g of potassium permanganate, the suspension turns from black to dark green, keep the temperature of the system below 5°C, and continue the reaction for 30min; (2) Move the reaction system to a warm water bath at 30°C to continue the reaction for 1h; (3 ) Slowly add 200ml of distilled water, while the temperature of the water bath is raised to 98°C, and react for 30min; Some strong acids, the obtained filter cake is fully washed with prepared 5% dilute hydrochloric acid, and finally washed to neutral with deionized water, and barium chloride is used to detect whether there is sulfate in the filtrate until no white precipitate appears in the filtrate. Dry the product ...

Embodiment 2

[0026] A kind of preparation method of graphene polyvinyl chloride resin composite material, comprises the following steps:

[0027] Step 1, the preparation of graphite oxide: (1) measure the concentrated sulfuric acid of the massfraction 98% of 118ml and add in the beaker, cool in ice-water bath; Slowly add 15g of potassium permanganate, the suspension turns from black to dark green, keep the temperature of the system below 5°C, and continue the reaction for 45min; (2) Move the reaction system to a warm water bath at 35°C to continue the reaction for 1h; (3 ) Slowly add 200ml of distilled water, while the temperature of the water bath is raised to 98°C, and react for 35min; Some strong acids, the obtained filter cake is fully washed with prepared 5% dilute hydrochloric acid, and finally washed to neutral with deionized water, and barium chloride is used to detect whether there is sulfate in the filtrate until no white precipitate appears in the filtrate. Dry the product in a...

Embodiment 3

[0033] A kind of preparation method of graphene polyvinyl chloride resin composite material, comprises the following steps:

[0034] Step 1, the preparation of graphite oxide: (1) measure the concentrated sulfuric acid of the massfraction 98% of 120ml and add in the beaker, cool in ice-water bath; Slowly add 15g of potassium permanganate, the suspension turns from black to dark green, keep the system temperature below 5°C, and continue the reaction for 60min; (2) Move the reaction system to a warm water bath at 40°C to continue the reaction for 1h; (3 ) Slowly add 200ml of distilled water, while the temperature of the water bath is raised to 98°C, and react for 40min; (4) Add 30% hydrogen peroxide to the suspension to remove potassium permanganate that has not participated in the reaction, heat filter to remove large Some strong acids, the obtained filter cake is fully washed with prepared 5% dilute hydrochloric acid, and finally washed to neutral with deionized water, and bar...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com