Plasma display apparatus

A plasma and display technology, applied in the direction of AC plasma display panels, gas discharge tubes/containers, instruments, etc., can solve the problems of rising manufacturing costs of plasma display panels, reduce initial discharge voltage, reduce manufacturing costs, and improve discharge Effect of Diffusion Efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0038] Hereinafter, the plasma display according to the present invention will be described in detail with reference to the drawings.

[0039] However, it should be noted that the plasma display according to the present invention is not limited to the embodiments described in this specification, and there may be multiple embodiments.

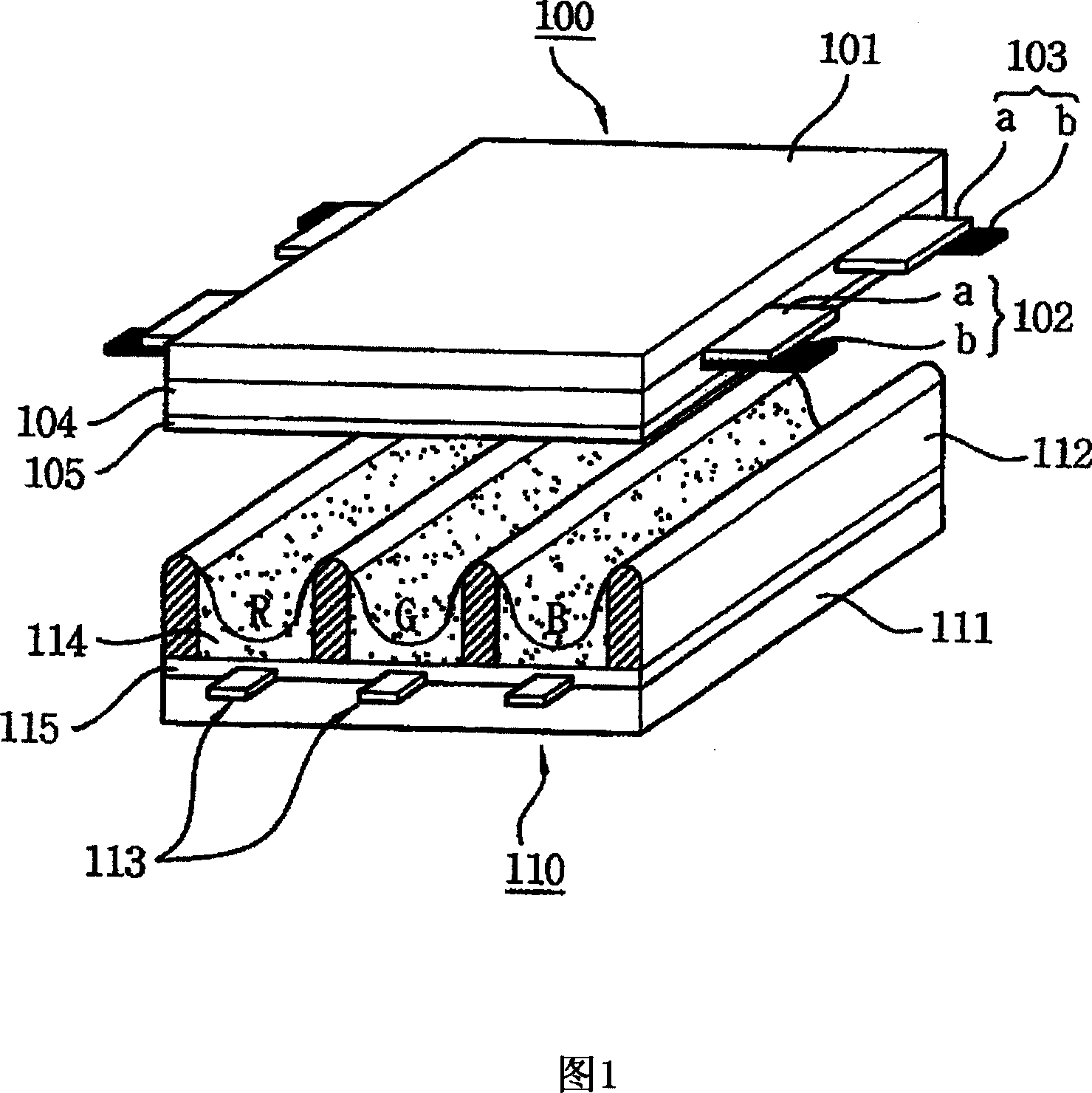

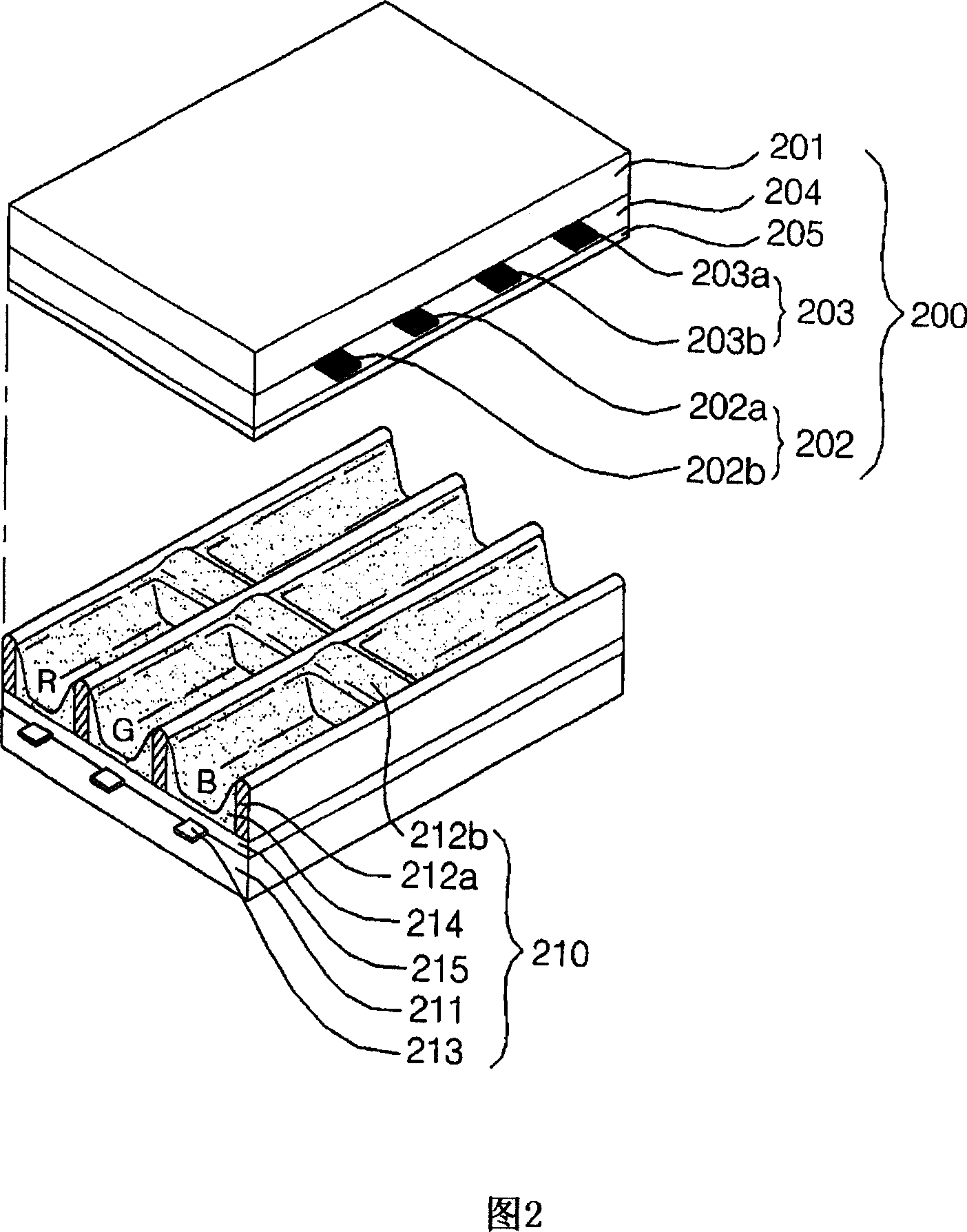

[0040] Hereinafter, the plasma display according to the present invention will be described in detail with reference to FIG. 2 to FIG. 17 . FIG. 2 is a perspective view showing one embodiment of a panel included in the plasma display according to the present invention.

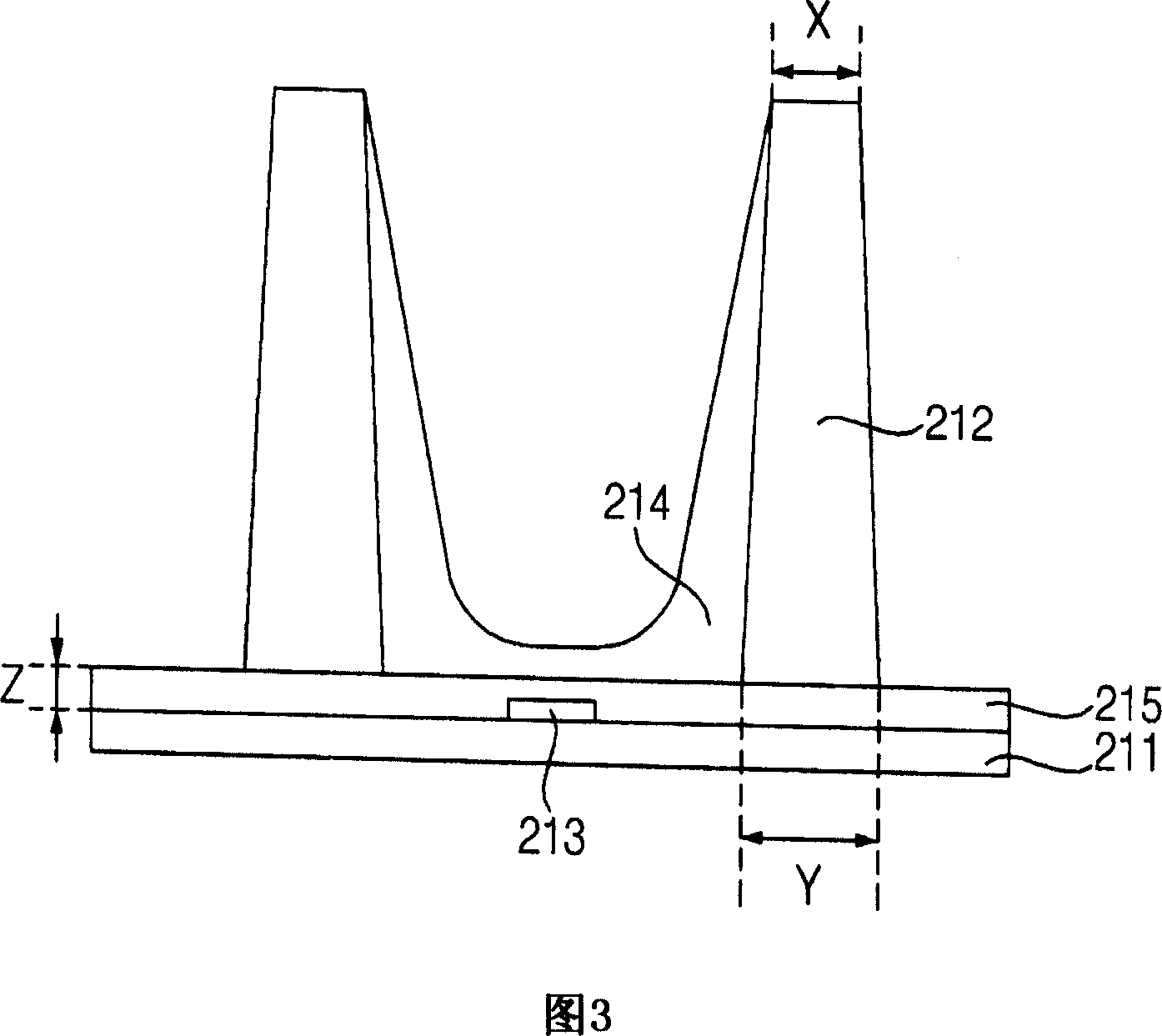

[0041]Referring to FIG. 2, the plasma display panel includes an upper panel 200 and a lower panel 210 glued at a prescribed interval. Address electrodes 213 formed on lower substrate 211 in a direction intersecting sustain electrode pairs 202 and 203 , and partition walls 212 formed on lower substrate 211 and partition a plurality of discharge cells are included.

[0042] Uppe...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com