Induction type synchronous motor

A synchronous motor and armature technology, applied in synchronous machines, electromechanical devices, electrical components, etc., can solve the problems of complex structure, unstable power supply, and reduced life, and achieve simplified structure, high power output, and extended life. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0072] Embodiments of the present invention will be described with reference to the drawings.

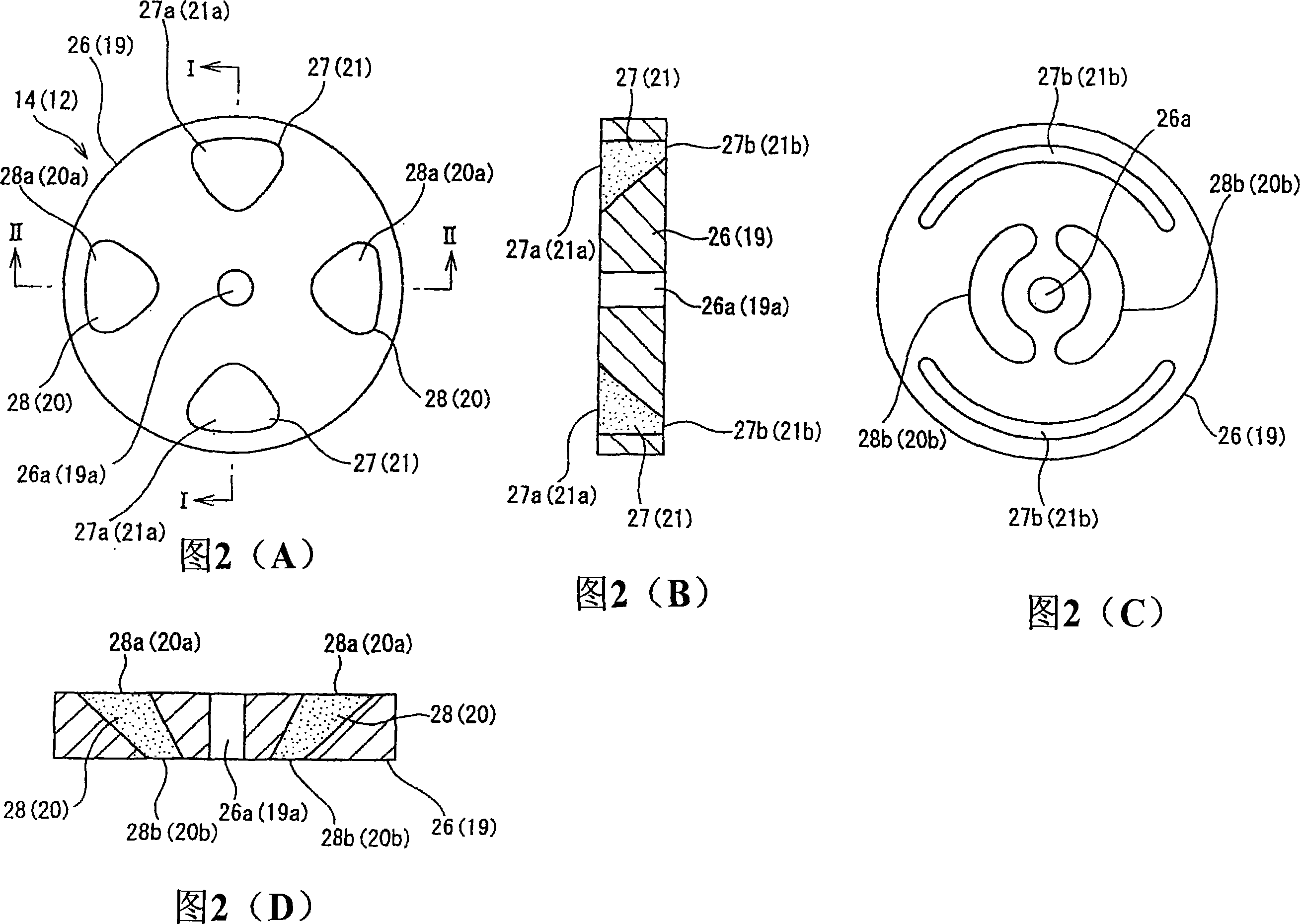

[0073] FIG. 1 shows an induction-type synchronous motor (induction-type synchronous motor) 10 according to a first embodiment.

[0074] The induction type synchronous motor 10 has an axial air gap structure in which the rotating shaft 34 penetrates the field stator 11 , the rotor 12 , the armature stator 13 , the rotor 14 , and the field stator 15 in sequence. The field stators 11, 15 and the armature stator 13 are fixed to the mounting surface G with an air gap provided with respect to the rotation shaft 34, and the rotors 12, 14 are assembled and fixed by providing an air gap from the rotation shaft 34 to the rotors 12, 14 to the axis of rotation 34 .

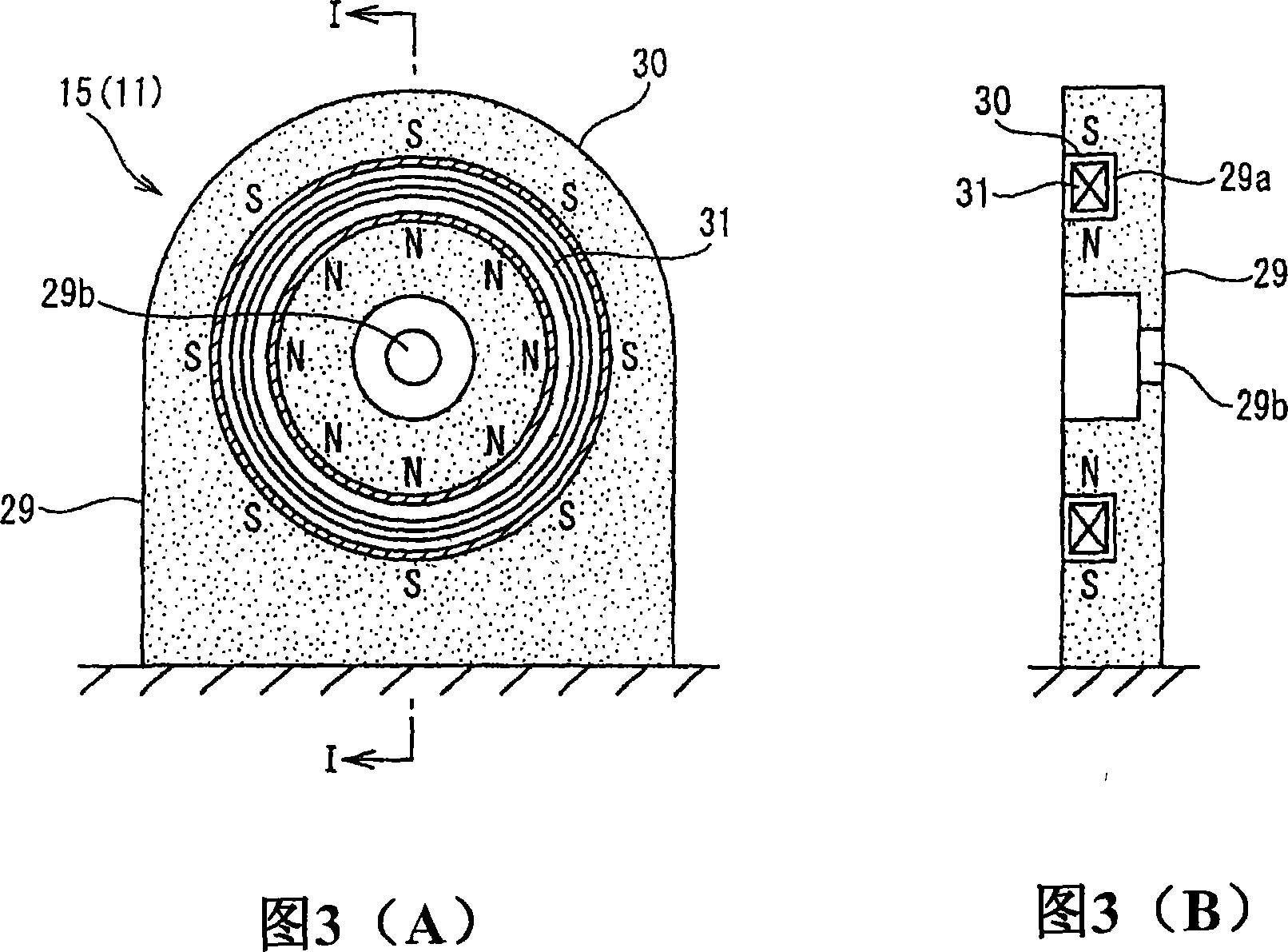

[0075] The field stator 11 and the field stator 15 are bidirectionally symmetrical with respect to the image. Therefore, one of the stators 15 is schematically shown in FIGS. 3(A) and 3(B).

[0076] Each field stator 11 , 15 has...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com