Fire grate assembly equipment of stalk gasification stove

A gasification furnace and grate technology, which is applied in coking ovens, special forms of dry distillation, petroleum industry, etc., can solve the problems of increased labor intensity for maintenance personnel, affecting the normal gas supply of users, increasing maintenance costs, etc., and prolonging tar cracking time, strong resistance to deformation, and increased gas production

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

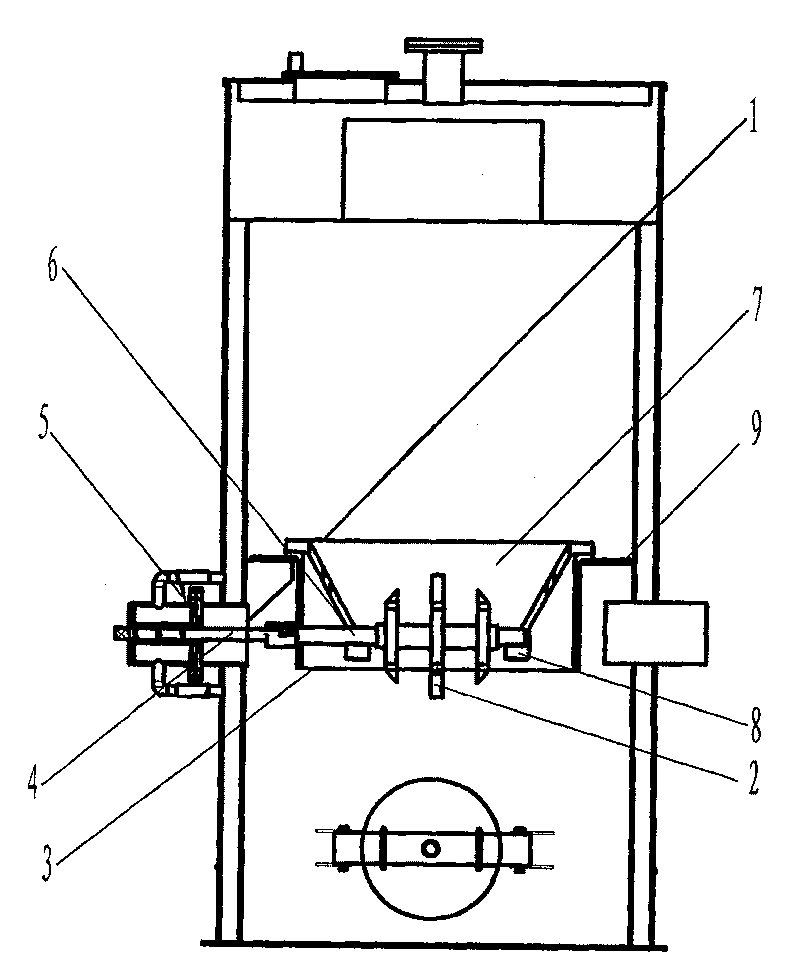

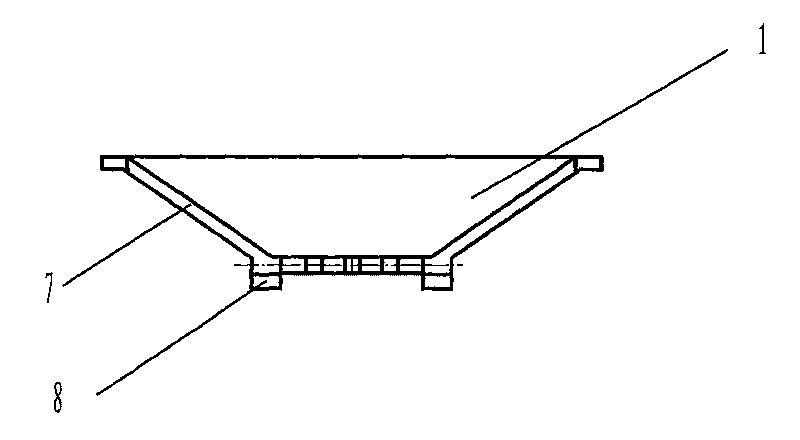

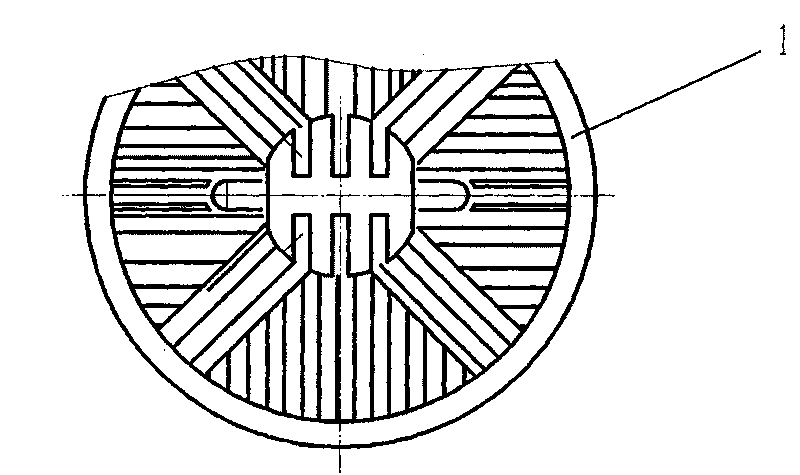

[0024] Depend on figure 1 -- Image 6 As shown, the straw gasification furnace grate assembly device of the present invention includes a conical grate 1, which is composed of a conical body 7 and a plane body 8, and has a conical basin structure as a whole. A round hole is respectively opened at both ends of the planar body 8, and the two ends of the rotating shaft 6 provided on the rotary grate 2 pass through the round holes respectively and are connected with the conical grate 1, and can rotate freely. 2 is a spherical sheet structure. A windshield 3 is arranged on the lower part of the conical grate 1, and the windshield 3 is a bucket-shaped structure with an upper opening and a lower part of the seal. There is a gap of 10cm between the bottom of the table-shaped fire grate and forms a closed area with the conical table-shaped fire grate. The windshield 3 is inserted on the furnace ring 9 and closely fits at an angle of 20° with the fitting of the furnace ring 9. One end...

Embodiment 2

[0026] The windshield 3 described in the present embodiment closely fits at an angle of 12° with the contact point of the conical fire grate 1, and the joint of the windshield 3 and the hoop 9 closely fits at an angle of 12°, and others are the same as in Embodiment 1.

Embodiment 3

[0028] The windshield 3 described in the present embodiment closely fits at an angle of 15° with the contact point of the conical fire grate 1, and the joint of the windshield 3 and the ring 9 closely fits at an angle of 15°, and others are the same as in Embodiment 1.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com