A hollow plastic T shape pile, and construction technique

A hollow, plastic technology, applied in artificial islands, sheet pile walls, water conservancy projects, etc., can solve the problems of high cost of concrete T-shaped piles, increase the self-purification ability of river water, and limit the water permeability of walls, etc., and achieve light weight and construction The effect of low difficulty and low cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

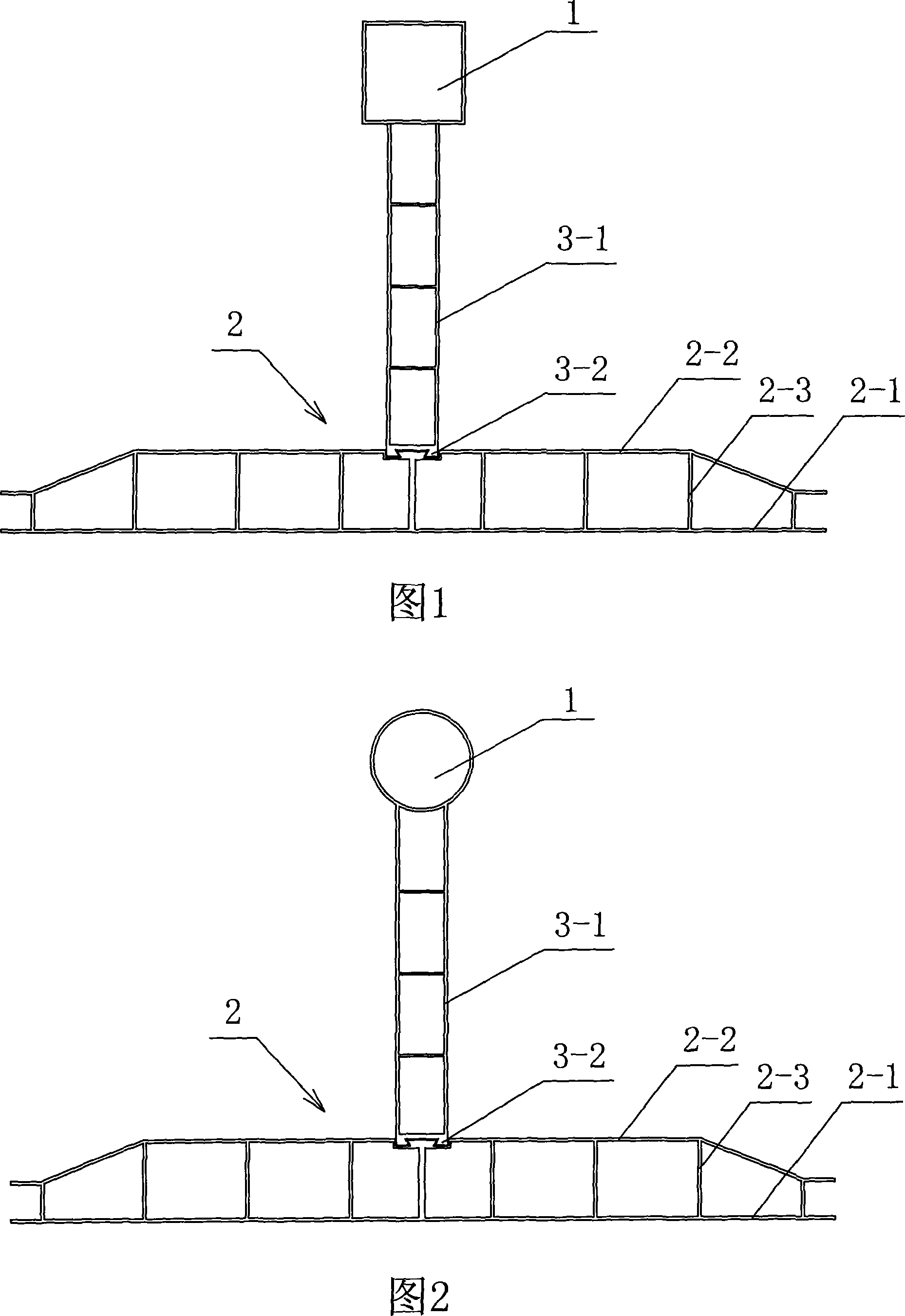

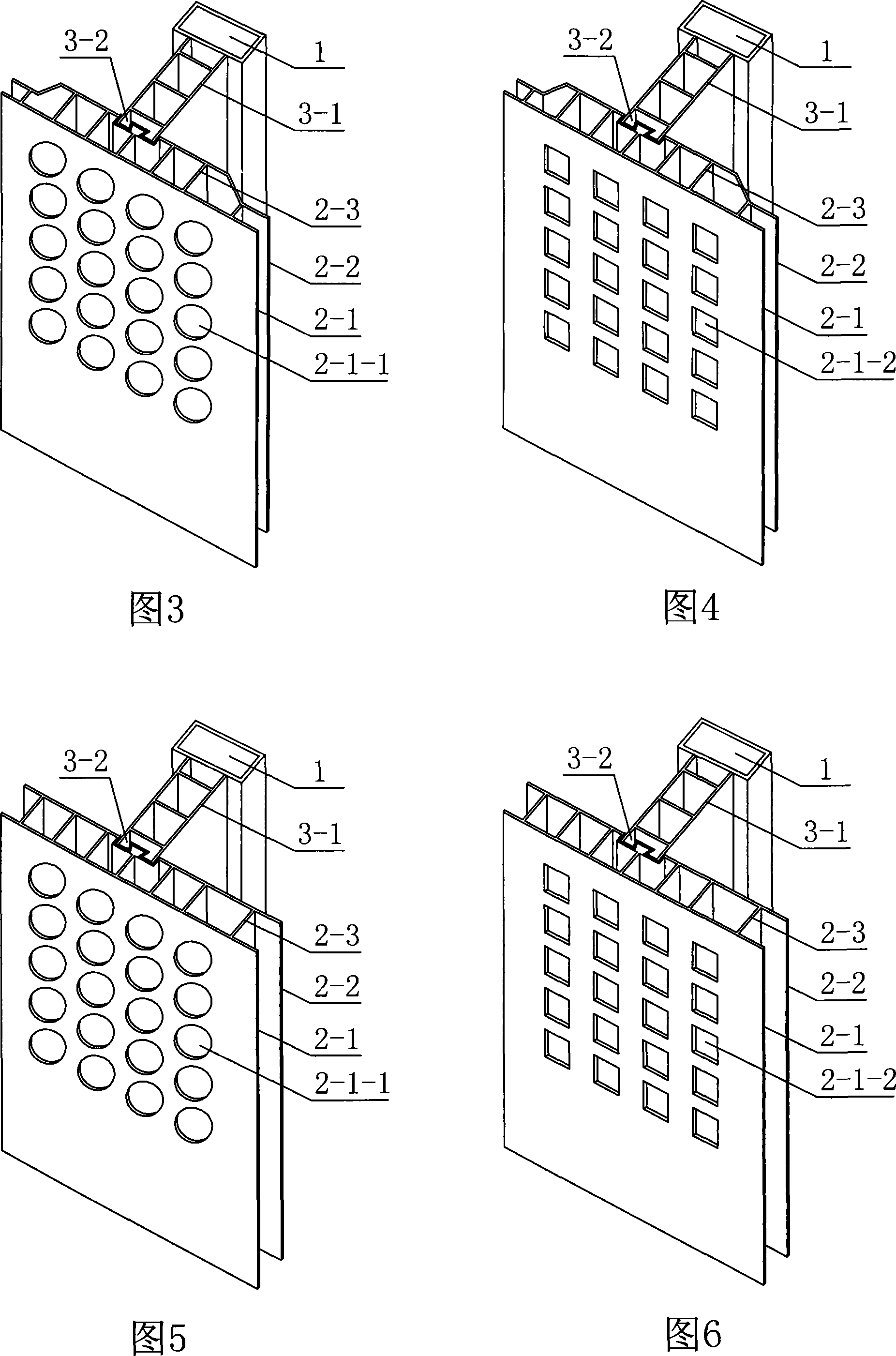

[0030] Embodiment 1, as shown in Figure 1, Figure 3, Figure 4, and Figure 11, in this embodiment, the material of the hollow plastic T-shaped pile is selected from PVC plastics, and the anchor plate 1 is a hollow rectangular tubular structure, and the anchor plate and the rib The board 3-1 is made into one body, the side board is a hollow corrugated board structure, and the other end of the rib board is formed with a dovetail groove 3-2; the panel 2 is also a hollow corrugated board structure, the front panel 2-1 is a flat board, and the rear panel 2 -2 The middle part is also horizontal, and a protrusion matching the dovetail groove is made in the middle position. This structure can make the rib plate and the panel movably connected, and the processing, transportation and construction are all more convenient. In this example, two sides of the rear panel The end is shaped with an inclined plane, which forms a trapezoid with the front panel, and there are ribs 2-3 perpendicular ...

Embodiment 2

[0031] Embodiment 2, as shown in Figure 5 and Figure 6, the basic structure of this embodiment is the same as that of Embodiment 1, that is, the anchor plate 1 is rectangular, the anchor plate and the rib 3-1 are integrated, and the rib and the panel 2 are movable Detachable, the ribs and panels are hollow corrugated structures, the only difference from Example 1 is that the front panel 2-1 and the rear panel 2-2 of the panel are flat, and similarly, there are tiny holes on the rear panel , There are larger round or square holes on the front panel.

Embodiment 3

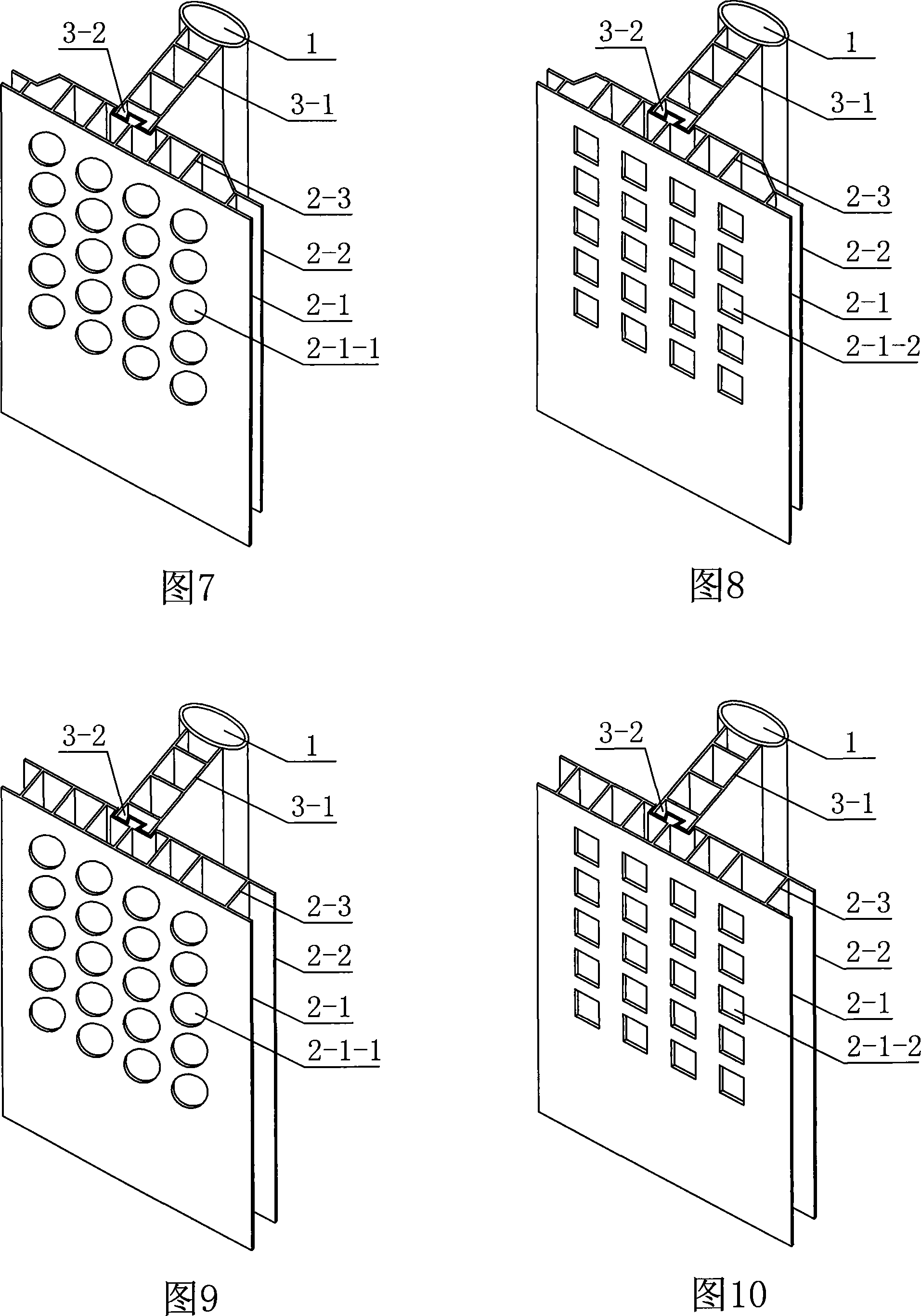

[0032] Embodiment 3, as shown in Fig. 2, Fig. 7, Fig. 8, Fig. 12 and Fig. 13, the anchor plate 1 of this embodiment is a hollow circular tube structure, the anchor plate and the rib 3-1 are integrated, and the rib It is a hollow corrugated board structure, and the other end of the rib plate is made with a dovetail groove 3-2; the panel 2 is also a hollow corrugated board structure, the front panel 2-1 is a flat plate, and the middle part of the rear panel 2-2 is also horizontal, in the middle position There is a protrusion matched with the dovetail groove. This structure can make the rib plate and the panel flexibly connected, which is convenient for processing, transportation and construction. In this example, slopes are formed at both ends of the rear panel, forming a trapezoidal shape with the front panel. , between the front and rear panels are vertical ribs 2-3. This example also offers dense microscopic holes 2-2-1 (shown in Figure 12) on the back panel, and its effect i...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com