Axial flow cooling blower fan

A cooling fan, axial-flow technology, applied in axial-flow pumps, mechanical equipment, non-variable pumps, etc., can solve the problems of power plant safety production and operation, affecting the cooling effect of air-cooled condensers, economic losses, etc. To achieve the effect of improving the heat dissipation effect, improving the heat dissipation effect, and enhancing the convective heat transfer capacity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0025] The present invention will be further described in detail below in conjunction with the accompanying drawings.

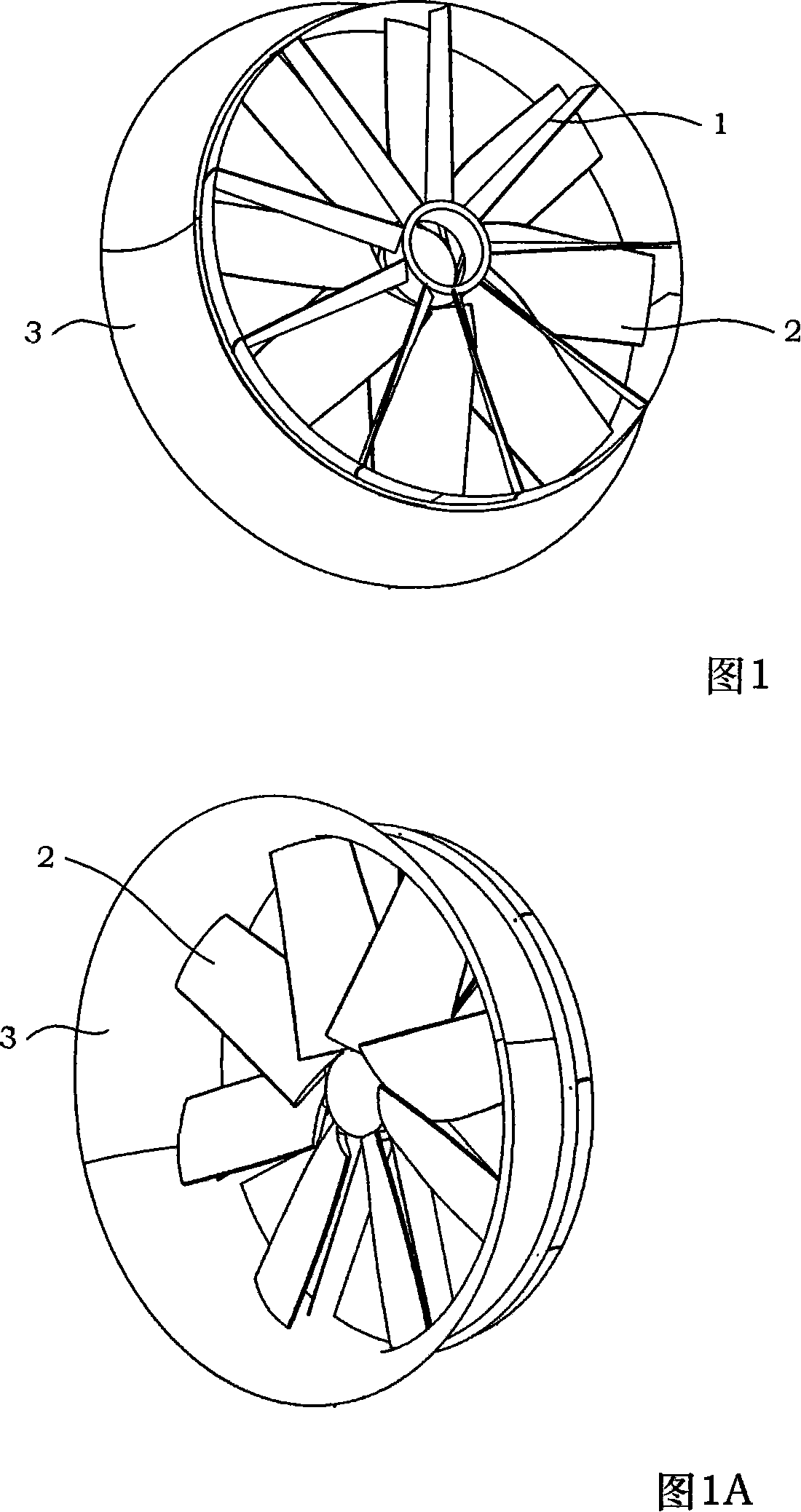

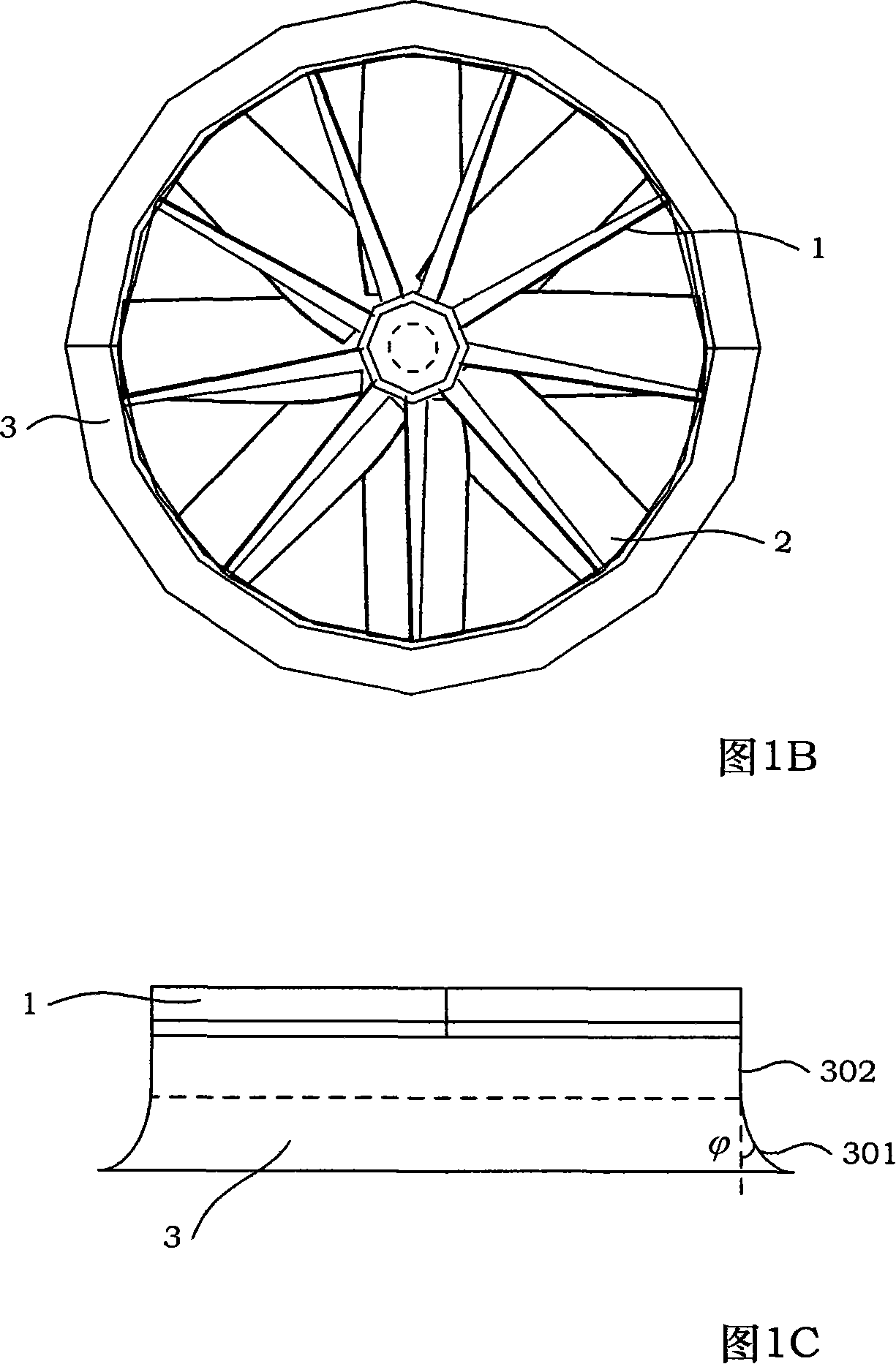

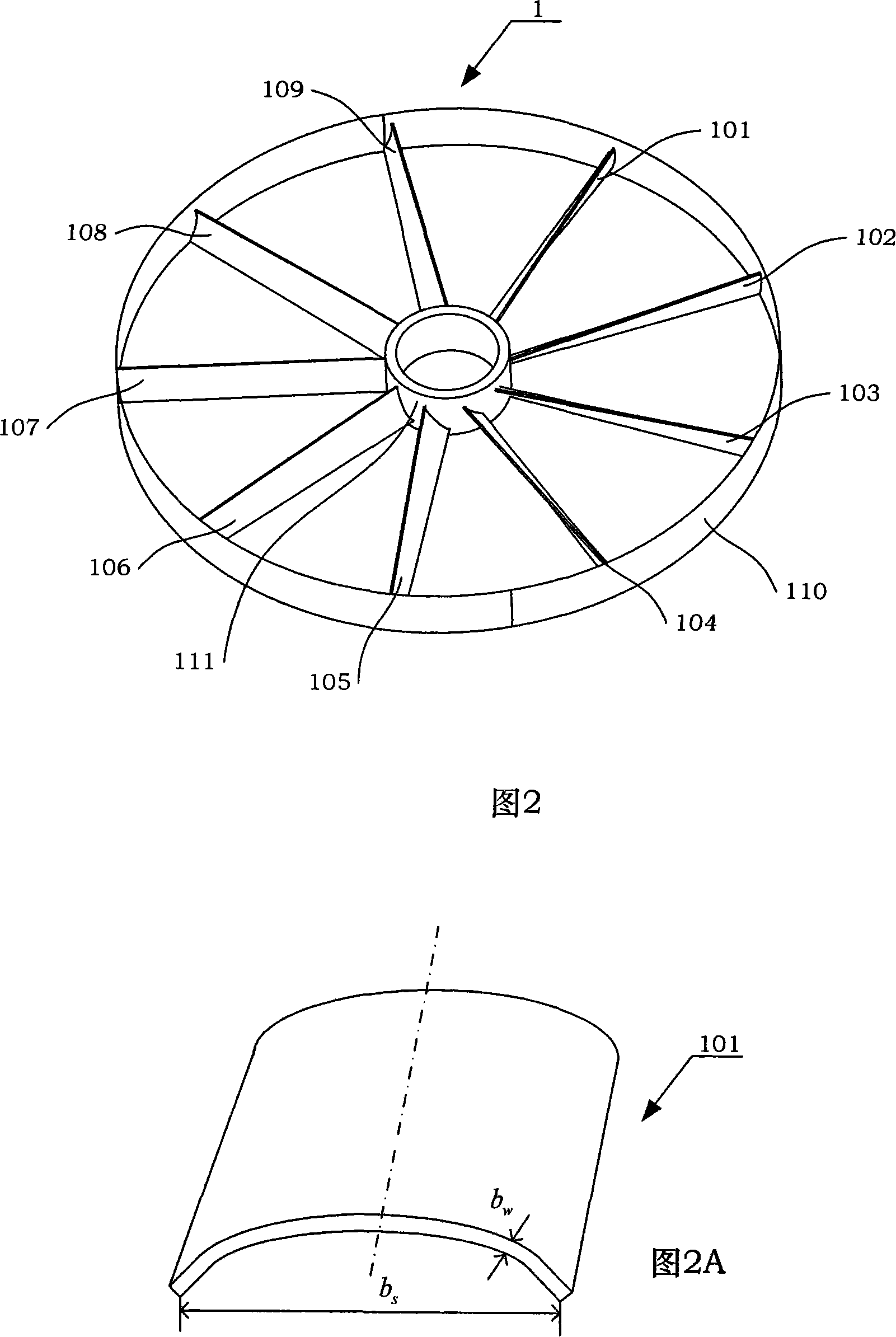

[0026] The present invention is a large diameter 8 ~ 10m, low pressure head 70 ~ 130Pa, high air volume 440 ~ 550m 3 The / s axial flow cooling fan is composed of a motor (not shown in the figure), an air coil 3, a deflector assembly 1 and a paddle assembly 2 (see Fig. 1, Fig. 1A, Fig. 1B), and the deflector The outer ring 110 of the vane assembly 1 is connected to the smooth section 302 of the wind ring 3, the blade assembly 2 is assembled in the wind ring 3, and the output shaft of the motor passes through the inner ring 111 of the deflector assembly 1 and the blade assembly 2 The hub 209 is connected. (See FIG. 1C ) The shape of the wind ring 3 is provided with a smooth section 302 and an expansion section 301 from top to bottom, and the expansion degree at the end of the expansion section 301 is 3-10 degrees. In the present invention, when the motor dr...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Ok | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com