Method for converting to hot air from flue gas in baking furnace

A roasting furnace, hot air technology, applied in heat exchanger types, direct contact heat exchangers, furnaces, etc., can solve problems such as ineffective utilization of waste heat resources, waste heat waste, and reduction in the amount of coal-fired supplements, to reduce The effect of coal-fired supplementary amount, energy saving, and meeting the needs of flue gas treatment process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

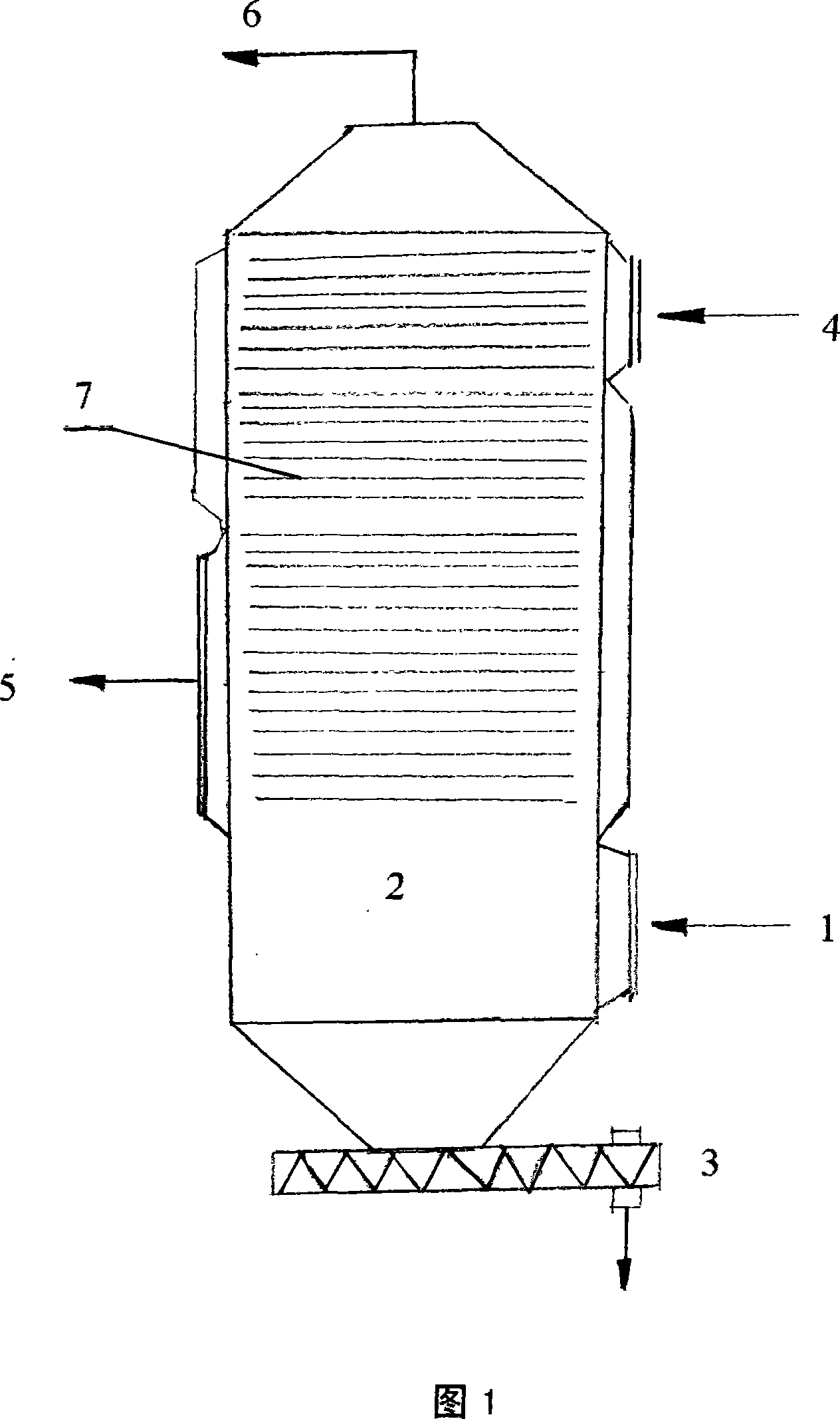

[0017] As shown in accompanying drawing 1, concrete steps of the present invention are as follows:

[0018] Step 1: Hot flue gas is introduced into the heat exchanger

[0019] The temperature of the hot flue gas 1 produced by the roasting furnace is 680°C, and the flue gas volume is 30,000m 3 / h, the hot flue gas 1 is introduced from the bottom of the heat exchanger 2 under the action of a high-temperature induced draft fan, and the dust contained in the hot flue gas is returned to the roasting system through the gravity settling chamber and the overflow screw 3;

[0020] Step 2: Cool air is fed into the heat exchanger

[0021] The temperature of the cold air 4 supplied to the heat exchanger is 20°C, and the supply volume of the cold air is 28000m 3 / h, the cold air 4 is fed from the upper part of the heat exchanger, and forms a three-stage countercurrent heat exchange form with the hot flue gas for heat exchange;

[0022] Step 3: Heat Exchange

[0023] The hot flue gas 1 ...

Embodiment 2

[0026] As shown in accompanying drawing 1, concrete steps of the present invention are as follows:

[0027] Step 1: Hot flue gas is introduced into the heat exchanger

[0028] The temperature of the hot flue gas 1 produced by the roasting furnace is 700°C, and the flue gas volume is 32000m 3 / h, the hot flue gas 1 is introduced from the bottom of the heat exchanger 2 under the action of a high-temperature induced draft fan, and the dust contained in the hot flue gas is returned to the roasting system through the gravity settling chamber and the overflow screw 3;

[0029] Step 2: Cool air is fed into the heat exchanger

[0030] The temperature of the cold air 4 supplied to the heat exchanger is 20°C, and the supply volume of the cold air is 30000m 3 / h, the cold air 4 is fed from the upper part of the heat exchanger, and forms a three-stage countercurrent heat exchange form with the hot flue gas for heat exchange;

[0031] Step 3: Heat Exchange

[0032] The hot flue gas 1 i...

Embodiment 3

[0035] As shown in accompanying drawing 1, concrete steps of the present invention are as follows:

[0036] Step 1: Hot flue gas is introduced into the heat exchanger

[0037] The temperature of the hot flue gas 1 produced by the roasting furnace is 720°C, and the flue gas volume is 33000m 3 / h, the hot flue gas 1 is introduced from the bottom of the heat exchanger 2 under the action of a high-temperature induced draft fan, and the dust contained in the hot flue gas is returned to the roasting system through the gravity settling chamber and the overflow screw 3;

[0038] Step 2: Cool air is fed into the heat exchanger

[0039] The temperature of the cold air 4 supplied to the heat exchanger is 20°C, and the supply volume of the cold air is 30500m 3 / h, the cold air 4 is fed from the upper part of the heat exchanger, and forms a three-stage countercurrent heat exchange form with the hot flue gas for heat exchange;

[0040] Step 3: Heat Exchange

[0041] The hot flue gas 1 i...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com