Method and device for solid waste continuous hydrothermal-treatment

A technology of solid waste and wet decomposition, which is applied in the fields of solid waste removal, organic fertilizer, climate change adaptation, etc., and can solve the problem that the harmless treatment rate is less than 20%.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0028] specific implementation plan

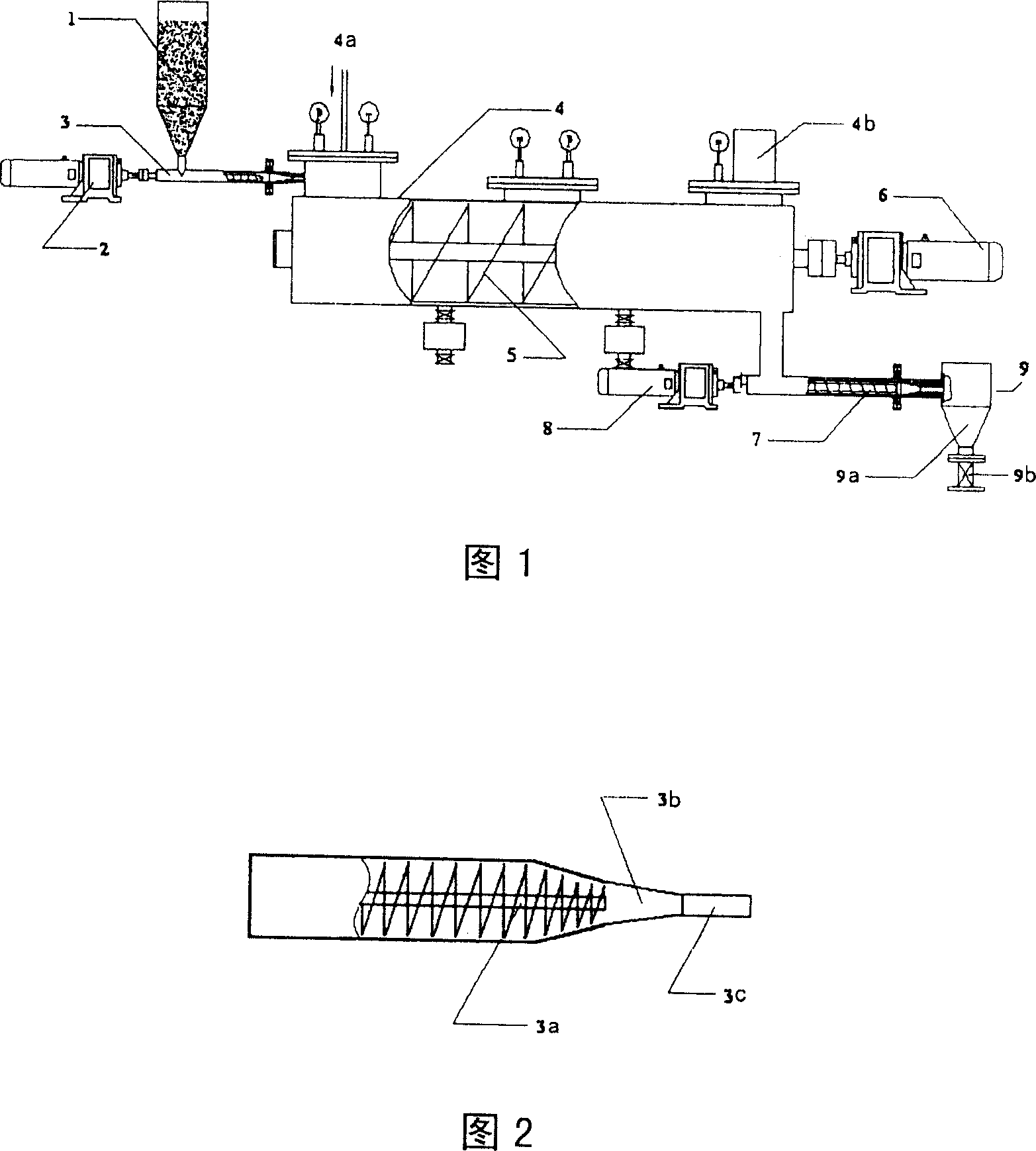

[0029] Please refer to Fig. 1 and Fig. 2, the device provided by the present invention, its solid waste enters the feed system 3 (the structure of this feed system 3 as shown in Figure 2) that is driven by feed motor and speed reducer 2 by hopper 1 After being conveyed and extruded by the conical screw 3a, the material enters the conical empty pipe section 3b, and in the conical empty pipe section 3b, due to the thrust behind and the resistance of the cone angle, the material is further extruded to form a dense The sealing plug enters the reactor 4 through the straight pipe transition section 3c.

[0030] The body of the reactor 4 is made of high-strength stainless steel, which is required to withstand a high temperature of 250°C and a high pressure of 35atm at the same time. A steam inlet 4a is installed on one side, and the straight pipe section 3c of the feed system 3 is connected to the steam inlet 4a. Considering that material enters...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com