Brake band holder

A brake band and brake device technology, applied in the direction of brake types, drum brakes, manufacturing tools, etc., can solve the problems of occupying a large space, and achieve the effects of saving space, reducing repair costs, and compact installation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

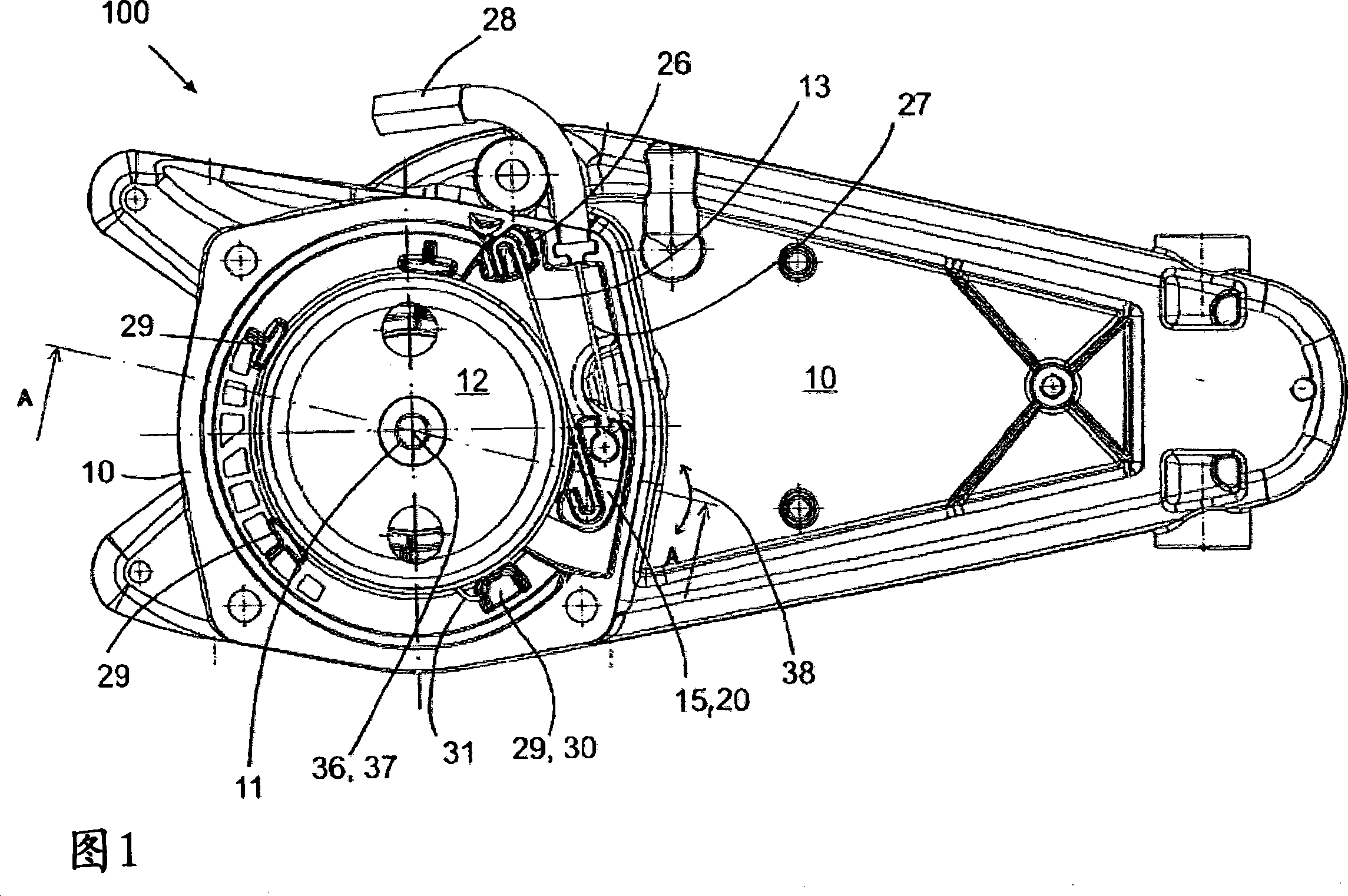

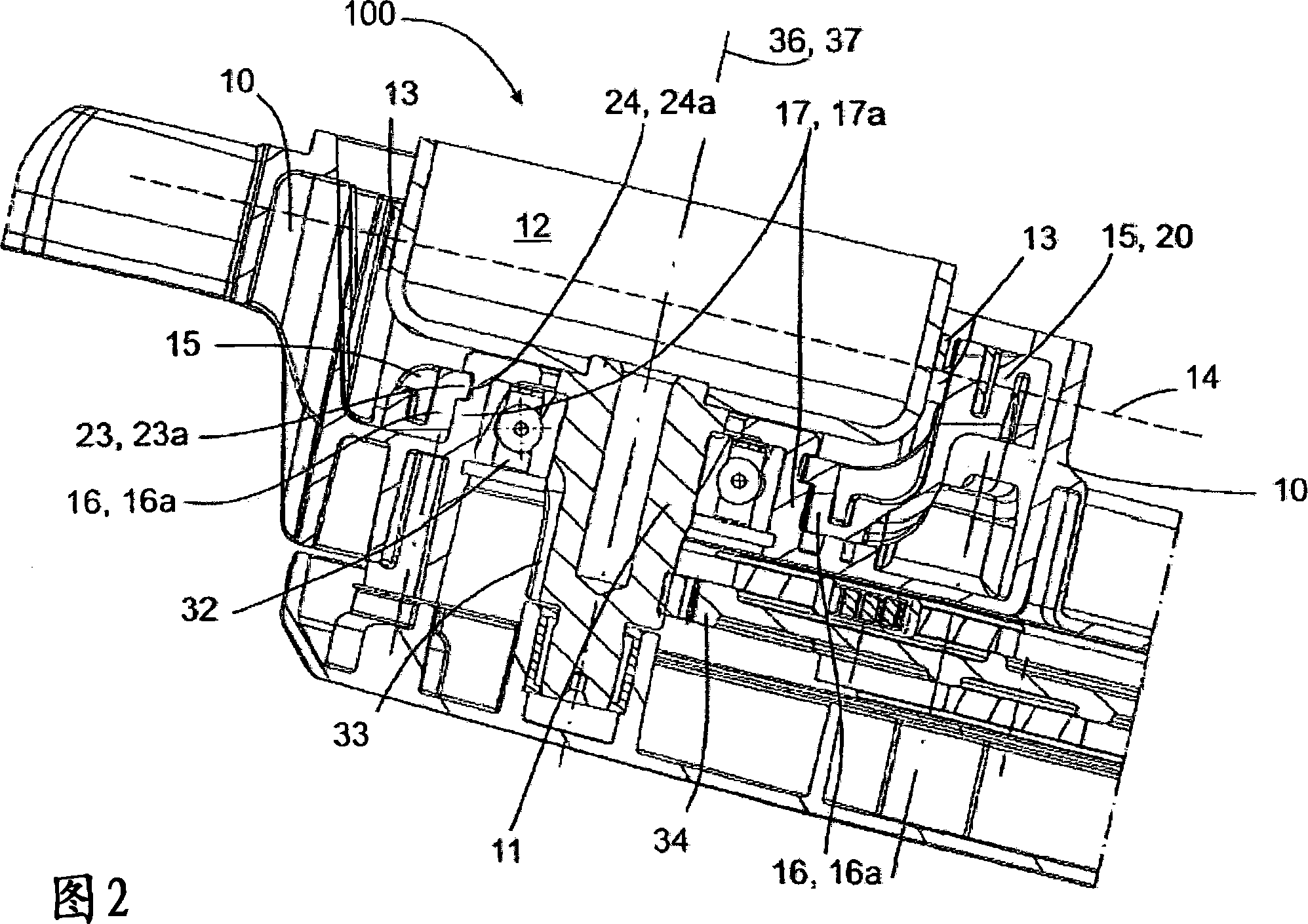

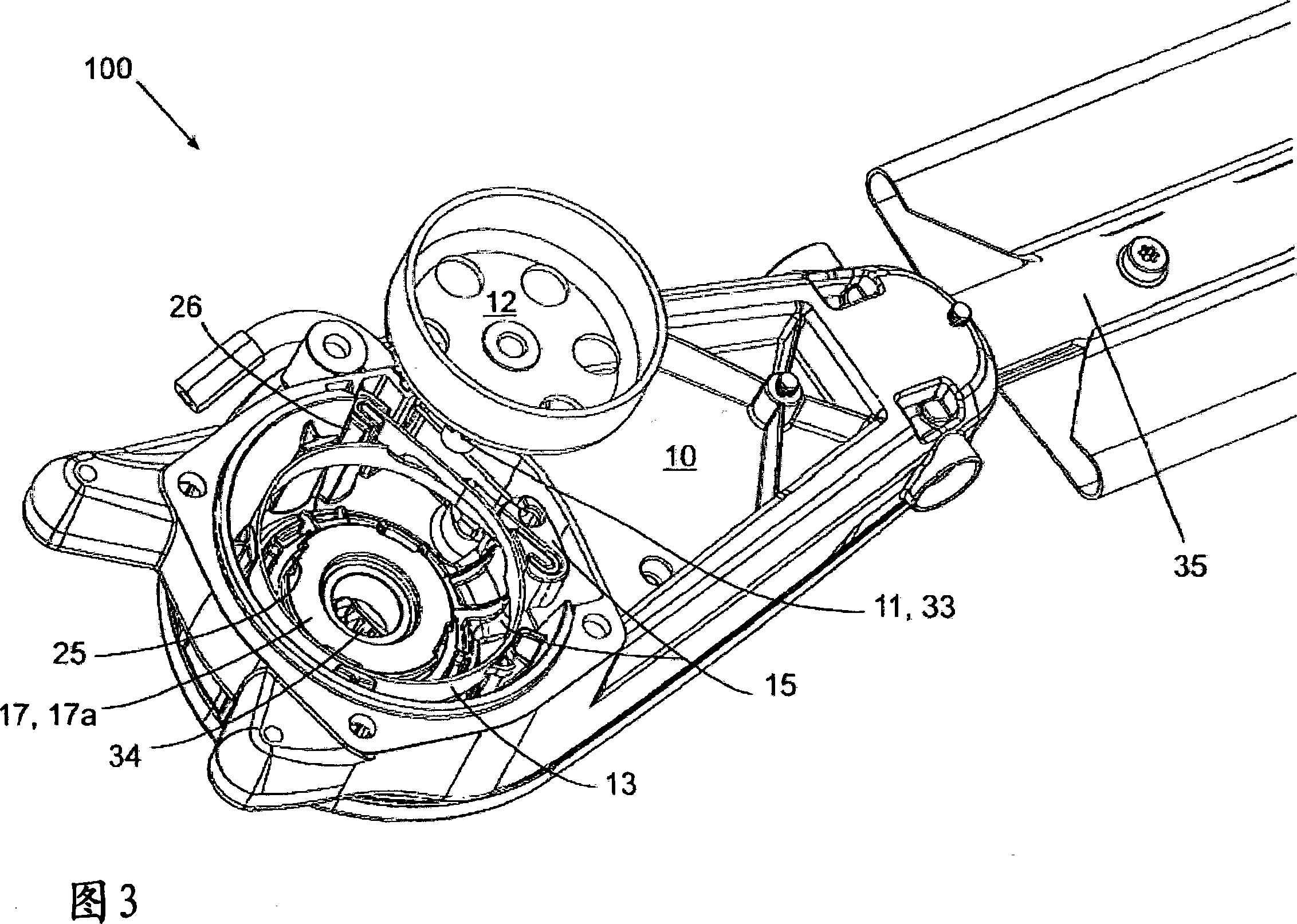

[0030]In FIG. 1 , the brake device 100 has a housing 10 . The associated hand tool with electric motor and starter unit is attached to this housing. However, the braking device 100 is shown without these components for simplicity. In FIG. 1 , the braking device 100 according to the invention is in a rest position, wherein the brake band 13 is under tension via the movable brake band support 15 . In order to obtain a braking effect on the shaft 11 , a brake band 13 is wound around a brake drum 12 connected to the shaft 11 . Also to ensure that the brake band 13 remains approximately in place in the operating position, radial guide rails 29 are arranged circumferentially around the brake drum 12 . At least one axial guide 30 is provided to cooperate with a protuberance 31 on the brake band 13 . In the present case, these axial guides 30 also serve as radial guides 29 for the brake band 13 . The brake band 13 is also shown under tension created by the fixed brake band support...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com