Screw type worm screw and worm strip transmission mechanism

A kind of transmission mechanism and helical technology, which is applied in the direction of transmission device, friction transmission device, mechanical equipment, etc., can solve the problems affecting the transmission accuracy, vibration, noise, load characteristics and difficulty of establishing lubricating oil film of gantry lathe machine and gantry milling machine , small width and space, etc., to achieve the effect of high transmission precision, simple structure, and less possibility of damage to the tooth surface

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0016] The present invention will be further described below in conjunction with the accompanying drawings in conjunction with the embodiments.

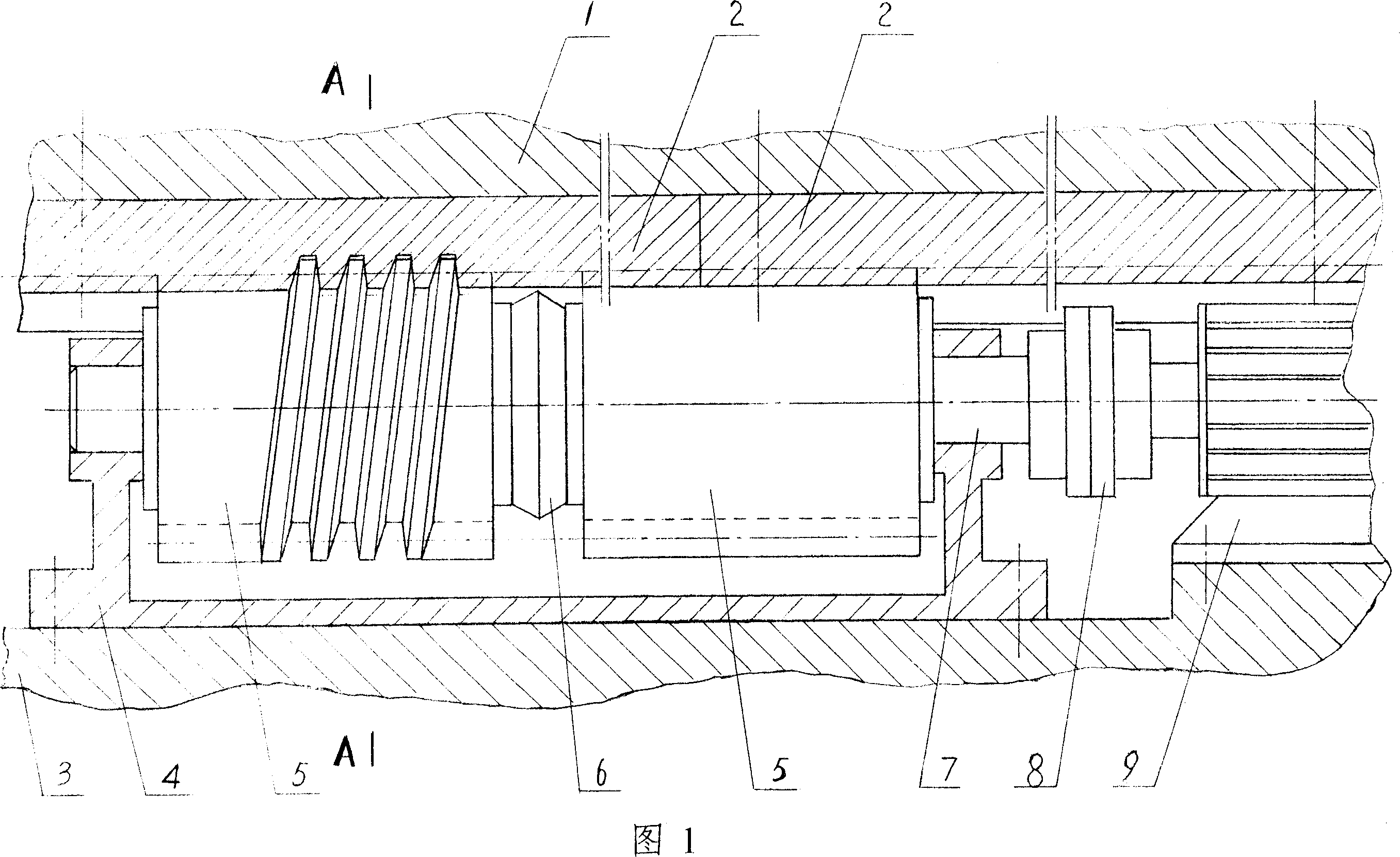

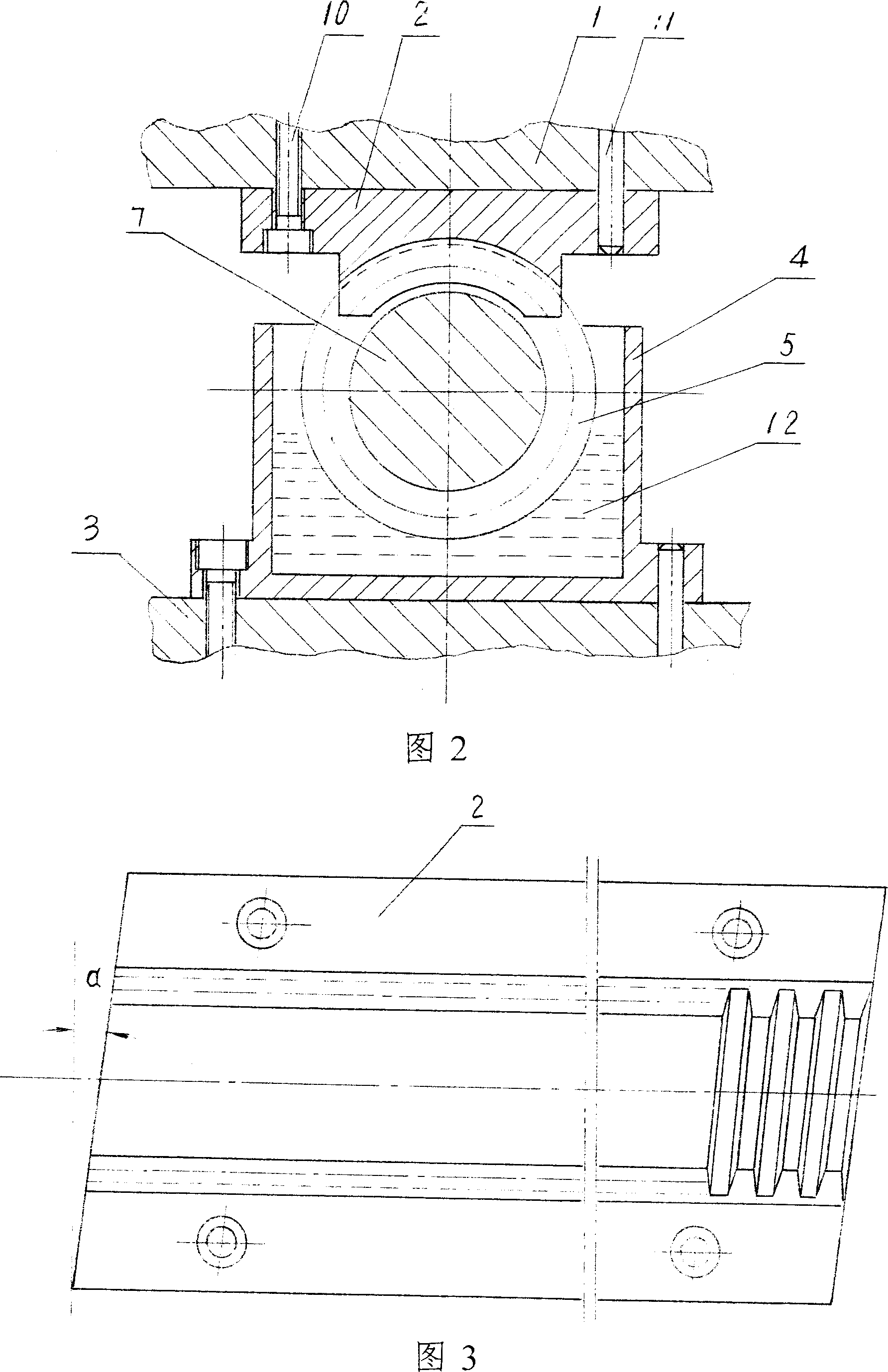

[0017] The helical worm gear transmission mechanism shown in the accompanying drawings includes a rotary structure and a linear motion structure. The rotary structure includes a housing 4 , a base 3 , a worm 5 , a butterfly spring 6 , a shaft 7 , a coupling 8 and a motor 9 . The linear motion structure contains a worm 2 and a workbench 1. The embodiment is the transmission mechanism of the XQT2014 type gantry milling machine workbench applying the present invention. The workbench 1 is 6m long, which is far longer than the single-section worm 2. Multi-section snails 2 are spliced. The present embodiment selects the splicing of the worm rods 2 with a length of 1.15m. λ is 3°15′45″, and the two ends of the worm strip 2 are cut along the helical teeth at 3°15′45″. Alveolar, connected end to end to form a complete tooth shape. The upp...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com