The electric heat mat controller

A technology for thermostats and carpets, which is applied in the field of thermostats for electric heating carpets, and can solve the problems of harmfulness to objects and life, increased costs, and low temperature control accuracy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

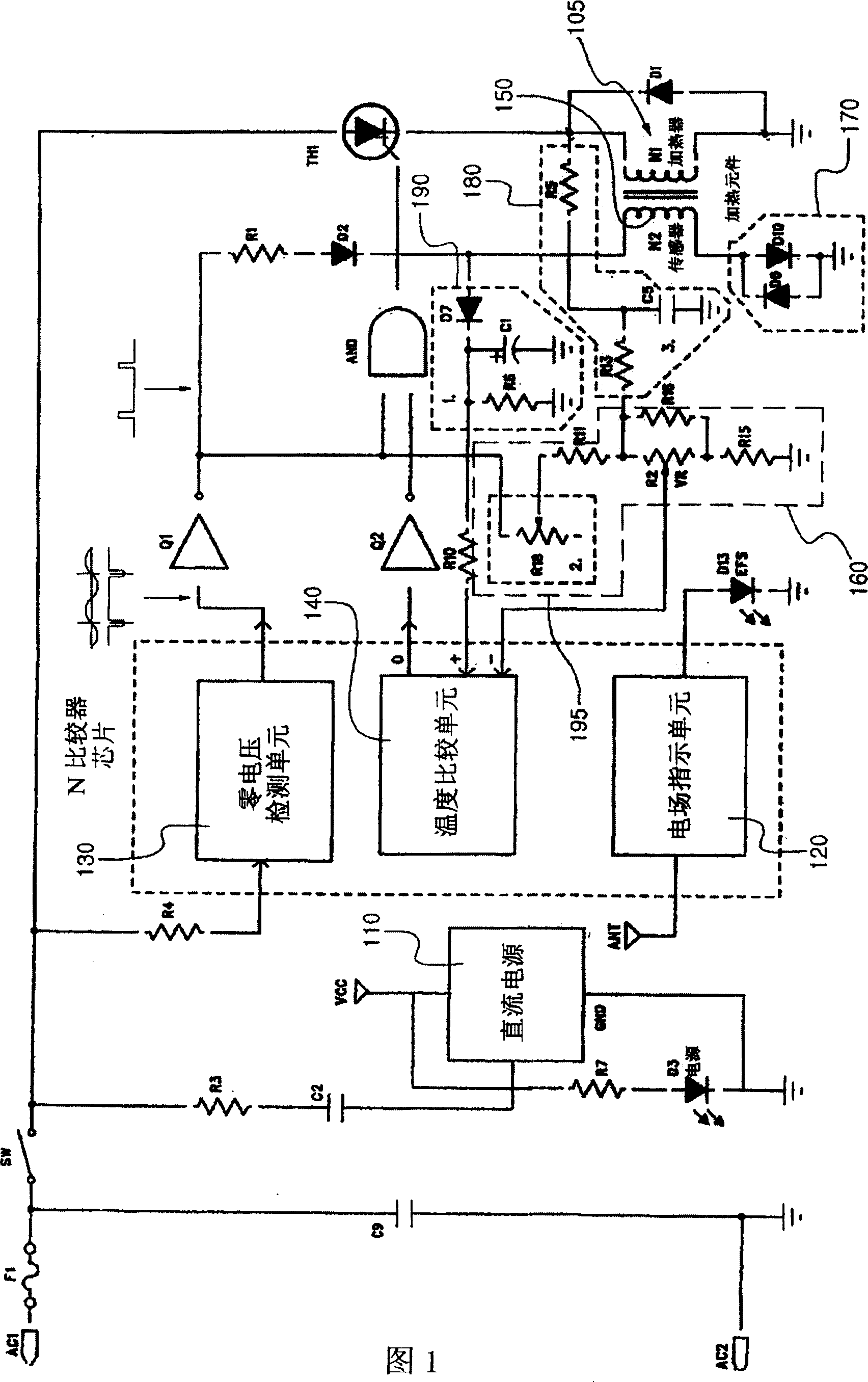

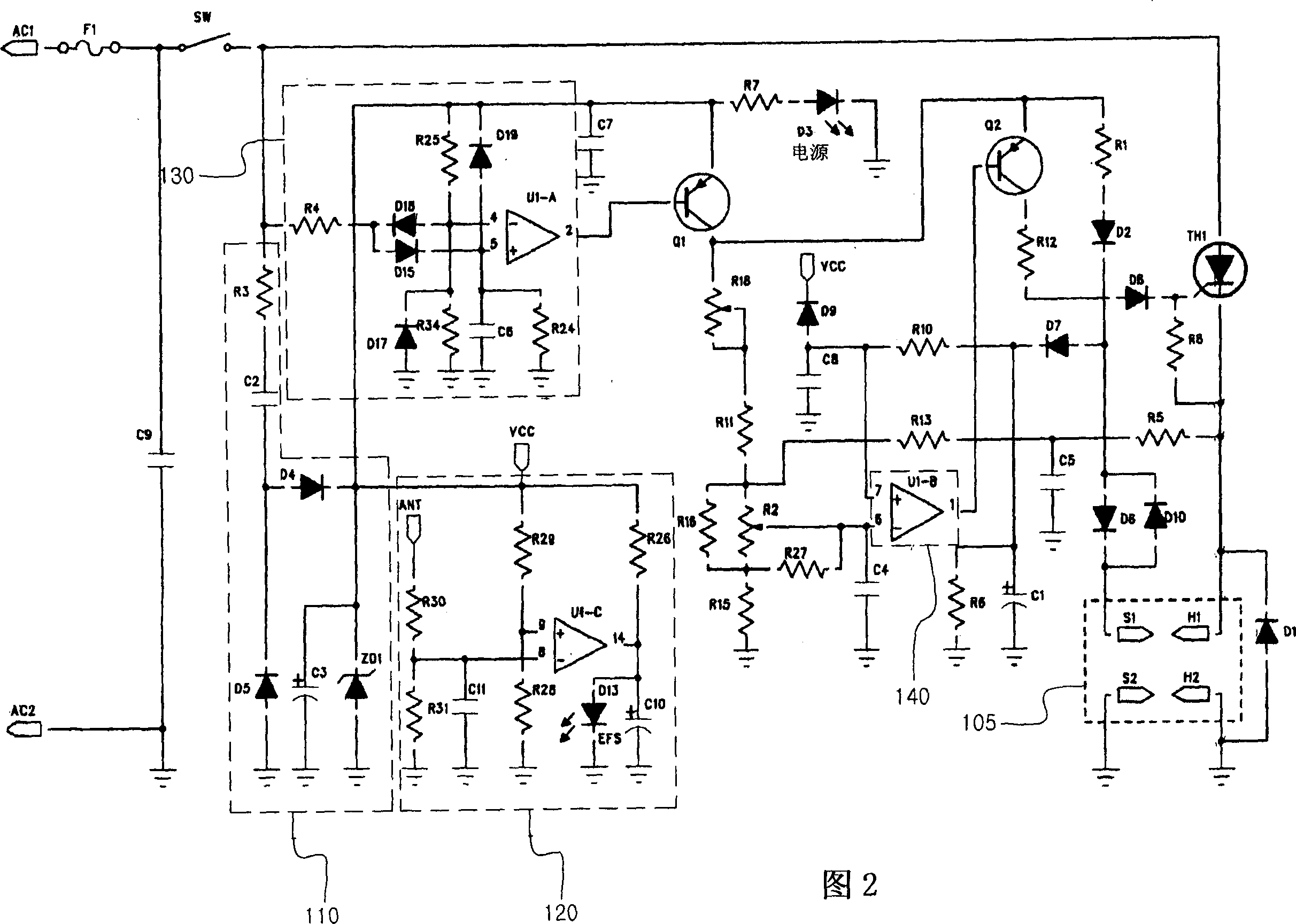

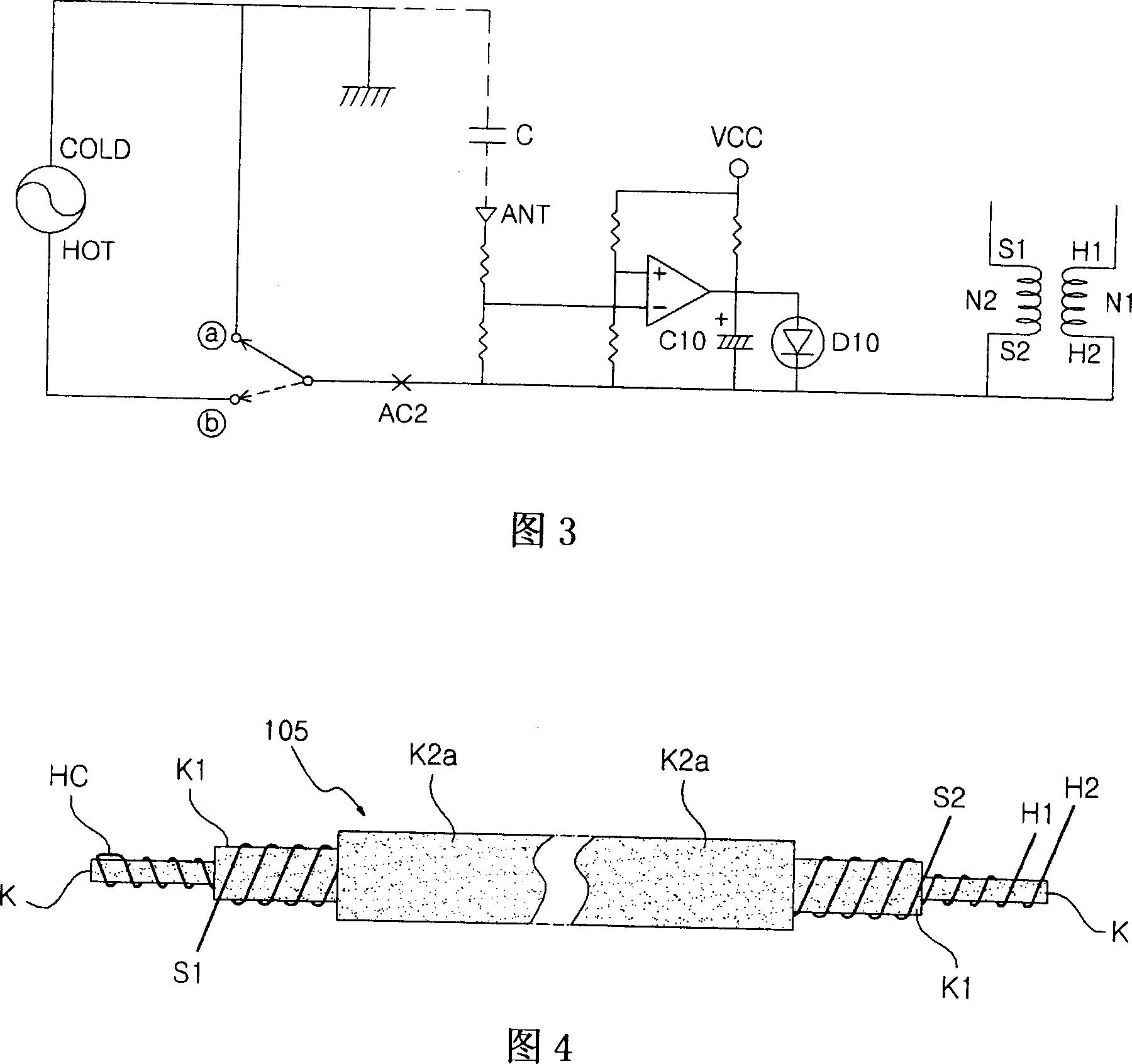

[0023] Referring now to the drawings, like reference numerals represent like or similar elements throughout the various drawings.

[0024] The temperature controller of the electric heating carpet according to the embodiment of the present invention will be described in detail below with reference to the accompanying drawings.

[0025] As shown in Fig. 1 and Fig. 2, the electric heating carpet thermostat of the present invention includes: a thermosensitive unit 105, an alternating current (AC) power line AC1 and AC2, a direct current supply unit 110, an electric field indication unit 120, a full-wave zero-voltage Detection unit (single zero voltage detection unit) 130, temperature comparison unit 140, temperature detection unit 150, temperature setting unit 160, temperature compensation unit 170, positive feedback circuit unit 180, safety protection circuit unit 190, and error correction circuit unit 195. The thermosensitive unit 105 is made up of cord-type thermosensitive wir...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com