Detecting device

A detection device and detection rod technology, which is applied in the direction of measuring/indicating equipment, metal processing machinery parts, metal processing equipment, etc., can solve the problems of different detection requirements and inaccurate detection, and achieve wide adaptability, high motion precision, The effect of easy operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

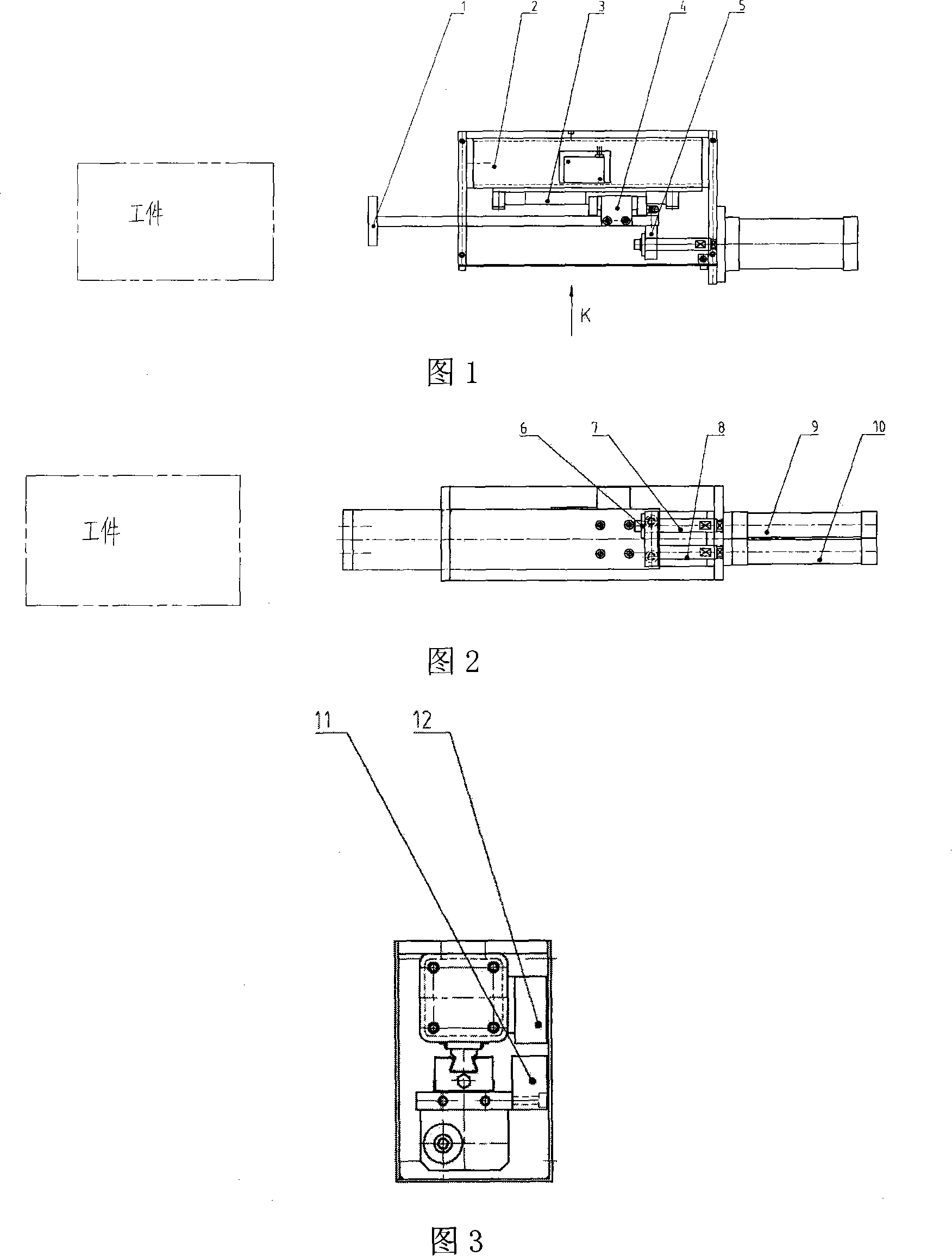

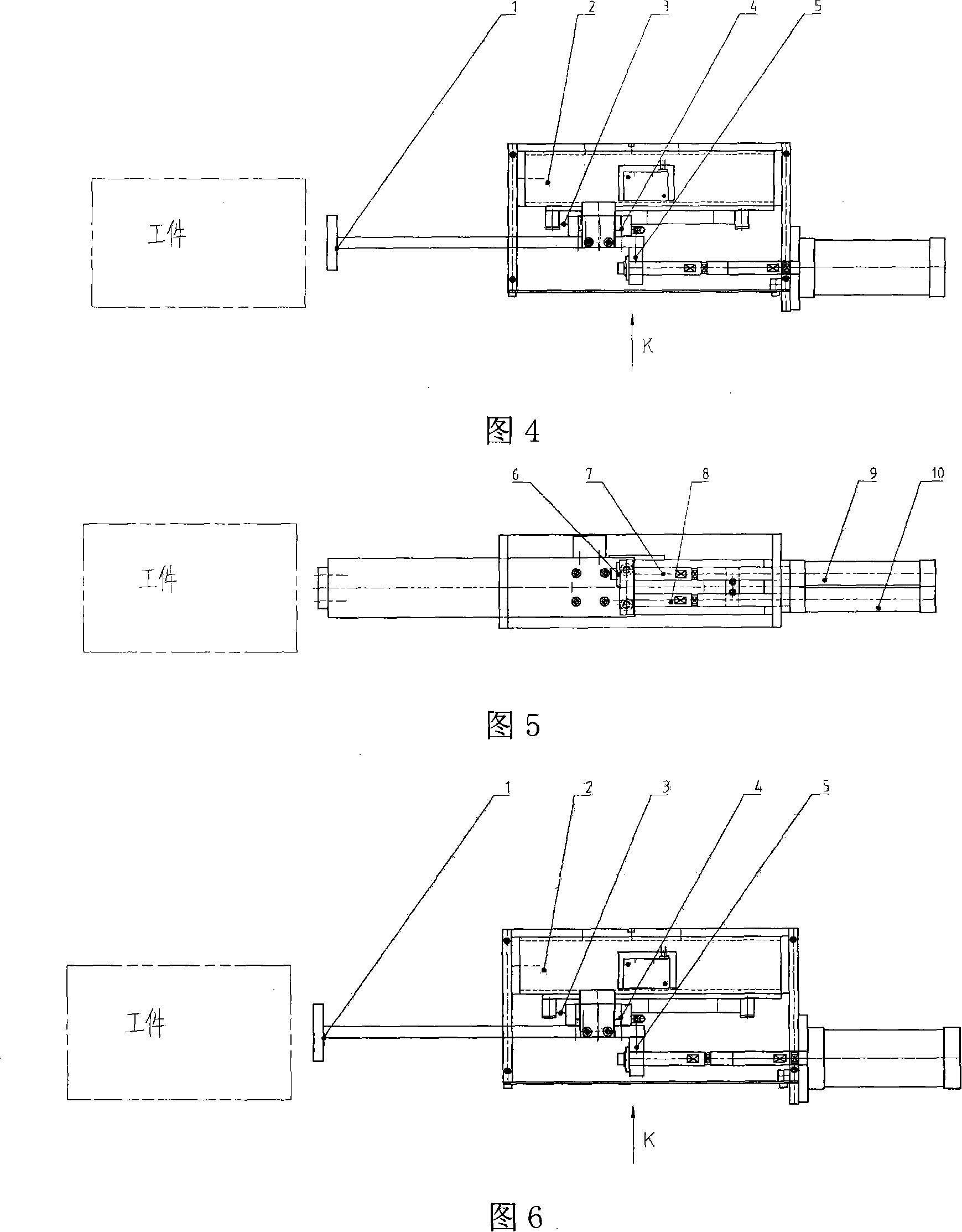

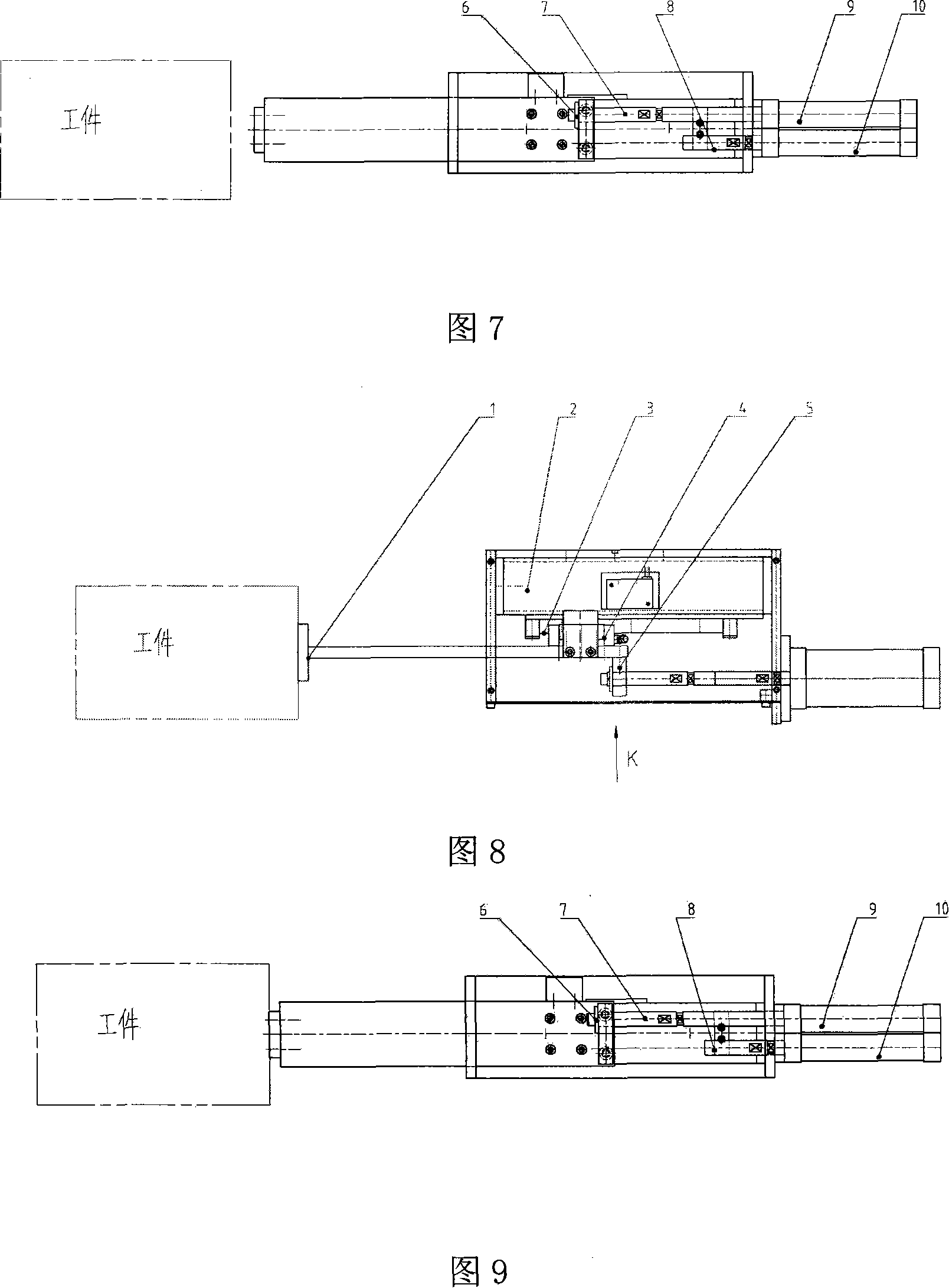

[0040] A detection device as shown in Figures 1 to 13, including a detection rod 1, a cylinder behind the detection rod 1 that can push the detection rod 1 to move, a linear guide rail 3 for making the detection rod 1 move linearly, and a The guide rail mounting base 2 of the linear guide rail 3 and the guide rail slider 4 , the position sensor 12 fixed on the guide rail mounting base 2 and the sensing block 11 installed on the detection rod 1 that can move with the detection rod 1 .

[0041] Among them, the linear guide rail pair composed of the linear guide rail 3 and the guide rail slider 4 mainly plays the role of guiding and positioning to ensure the accuracy of the detection device; the detection rod 1 is installed on the guide rail slider 4, and it mainly plays the role of contacting the workpiece; The main function of the position sensor 12 is to detect the position of the sensing block 11 so as to issue instructions to the control system.

[0042] There are two cylind...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com