Steel rail space adjuster

A technology of adjuster and gauge, applied in the direction of track, laying track, measuring instrument, etc., can solve the problems of unsuitable high-speed passenger dedicated line laying and maintenance, etc., and achieve the effect of safe use, fast adjustment and convenient portability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

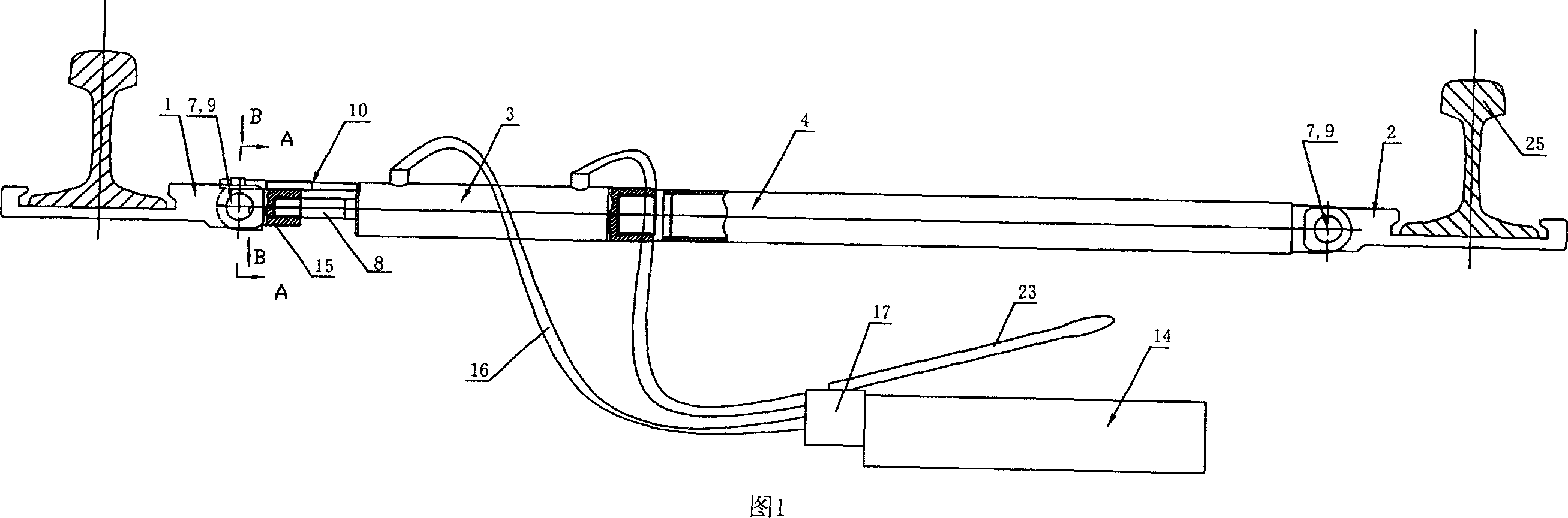

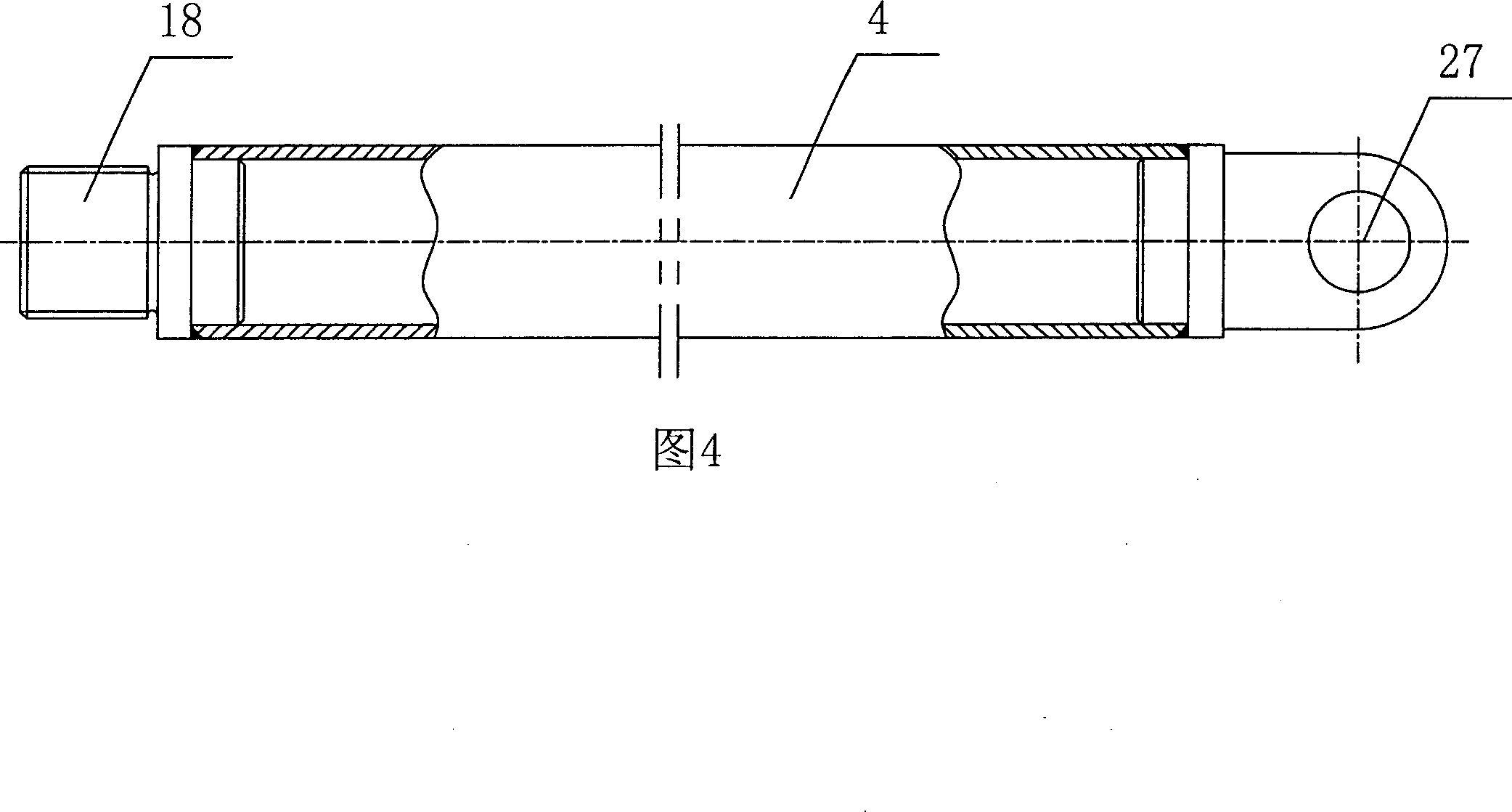

[0036] The rail gauge adjuster shown in Figure 1 includes a connecting rod 4 whose right end is insulatedly connected to the right deck 2, and the left end is connected to the hydraulic cylinder 3. The piston rod connector 15 of the hydraulic cylinder 3 is insulated and connected to the left deck 1. The rod connector 15 is equipped with a scale 10 that can be elastically stretched between the piston rod connector 15 and the cylinder head of the hydraulic cylinder 3. The hydraulic cylinder 3 is connected to the hydraulic control pump 17 through the oil pipe 16, and the hydraulic control pump 17 is connected to the oil cylinder 14. .

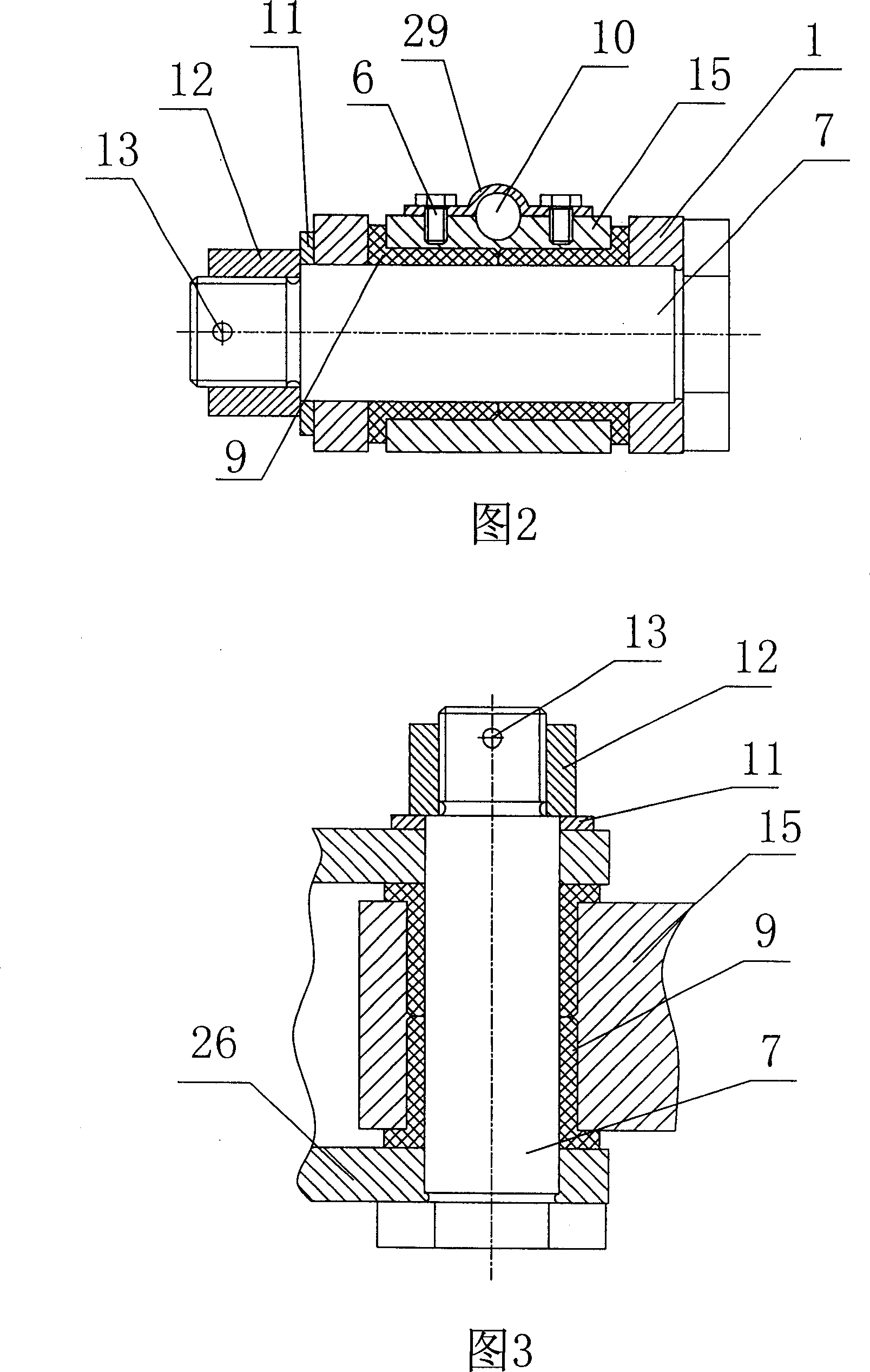

[0037] As shown in Fig. 3, Fig. 6 and Fig. 7, the inner ends of the left card holder 1 and the right card holder 2 for clamping the rail 25 are correspondingly provided with axial connecting plates 26 with radial concentric holes. As shown in FIG. 5 , the inner end of the connecting head 15 of the piston rod of the hydraulic cylinder 3 is provided...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com