Soil cement fixed pile wall based on foundation ditch supporting and construction method thereof

A support technology for cement-soil walls and foundation pits, applied in sheet pile walls, foundation structure engineering, construction, etc., can solve the problems that cement-soil walls cannot be embedded into pebble layers, and achieve the effect of preventing overturning

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

example 1

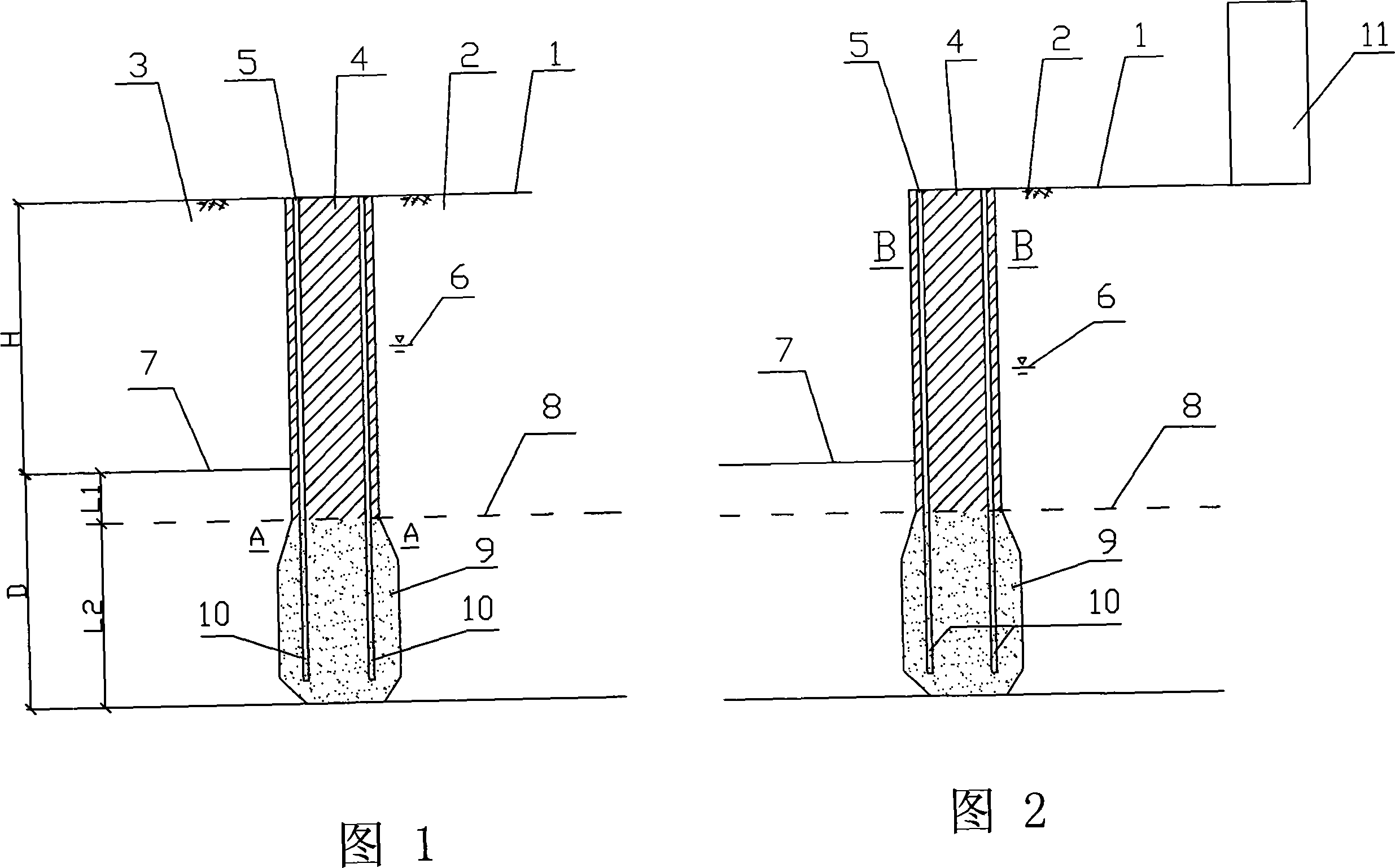

[0020] The soil layer at the bottom of the foundation pit is silty clay, partially silt, with a thickness of 1.0-2.0m, below which is a pebble layer, the groundwater level is -3.5m, and the depth of the foundation pit is 5m, which does not meet the requirements for anti-piping and anti-overturning . Cement-soil walls are used for support and anti-seepage.

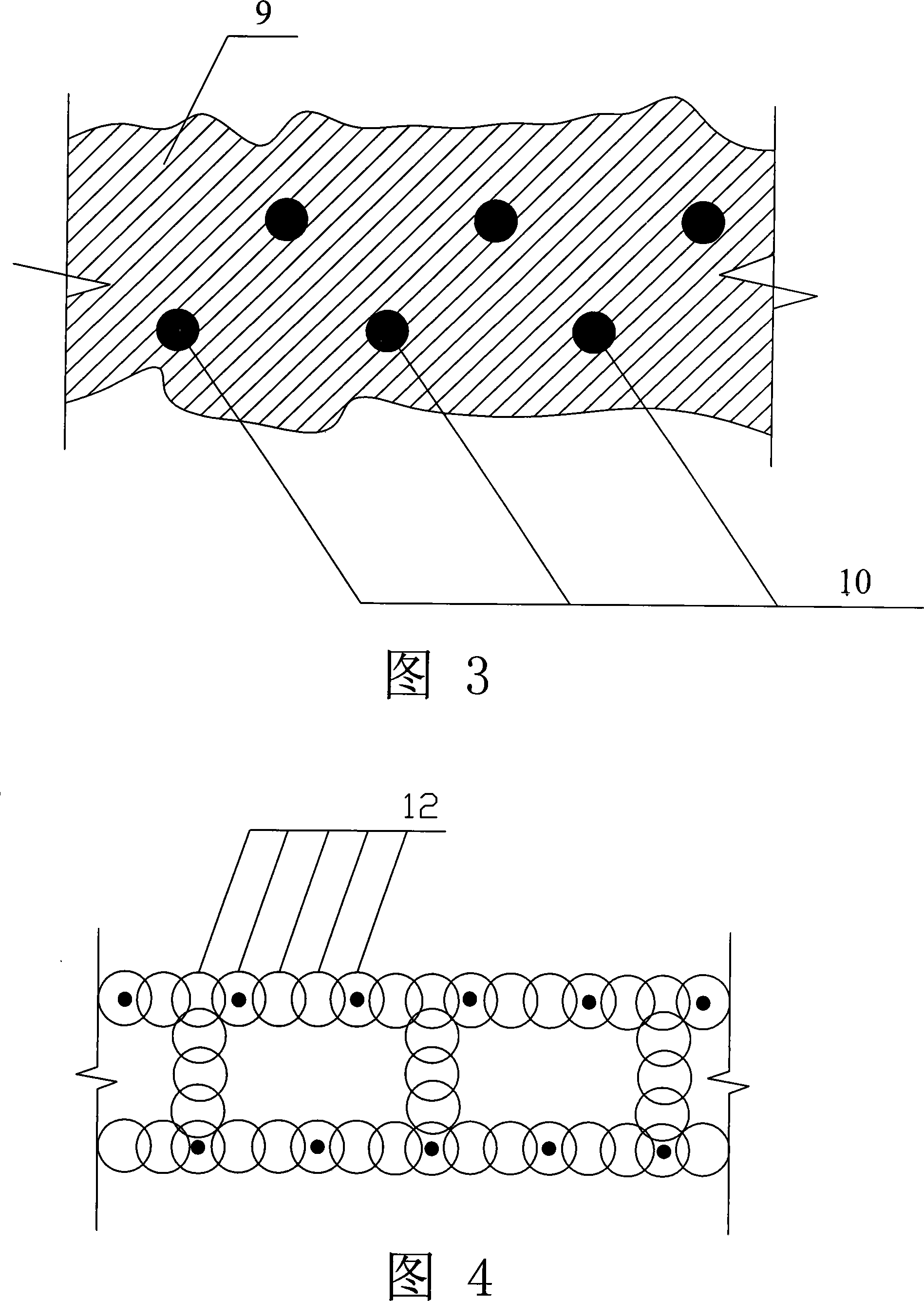

[0021] As shown in Figure 2 and Figure 3, the cement-soil wall is arranged according to the drawings, and the cement-soil wall is overlapped by cement-soil mixing piles and arranged in the form of a grid. Carry out the cement-soil mixing pile construction from the ground down, the pile diameter is 500mm, and stop when the pile is formed until the top surface 8 of the pebble layer, and the buried depth of the top surface 8 of the pebble layer is about 6-12m. According to the calculation, in the area of the retaining wall where the pebble layer is buried 6-8m deep, the soil layer at the bottom of the foundation pit is basi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com