Constant-speed differential speed double-axis reverse output transmission method and device

A technology of reverse output and speed change device, applied in transmission, aircraft transmission, gear transmission and other directions, can solve the problems of flight height change, destroy flight attitude, change lift and other problems, achieve accurate transmission ratio, ensure reliability, The effect of reducing friction

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0017] The present invention will be described in detail below in conjunction with the accompanying drawings and embodiments.

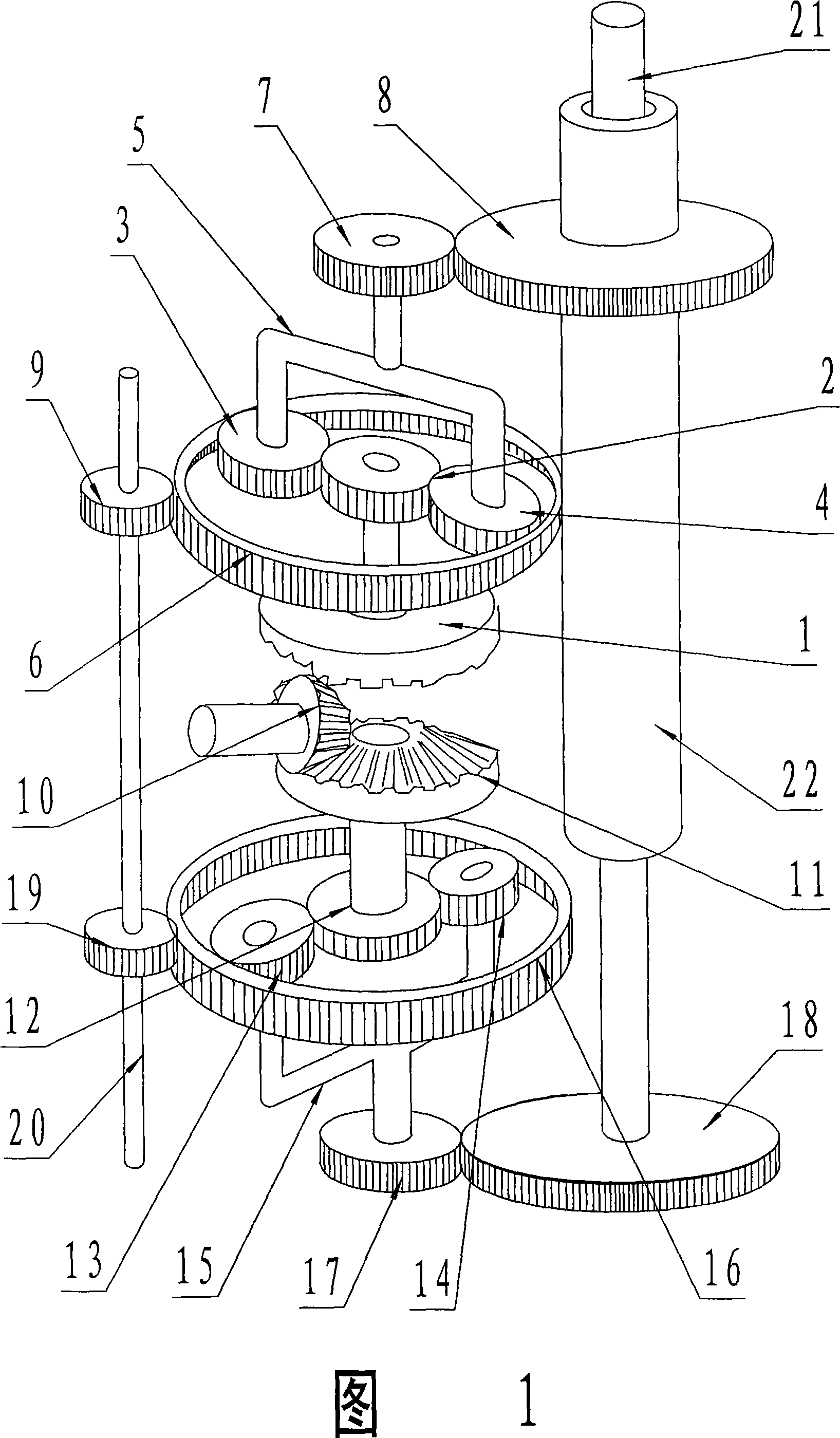

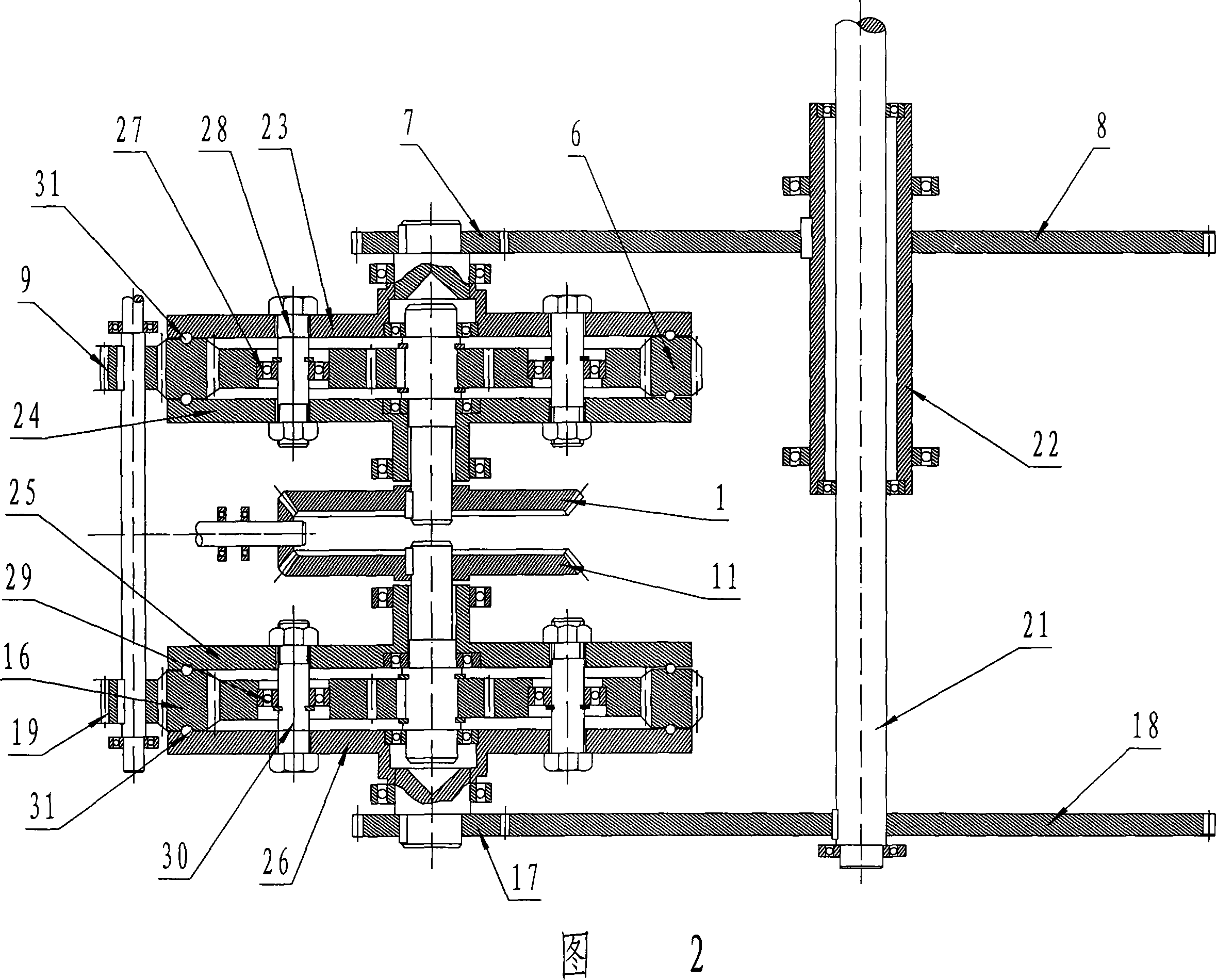

[0018] As shown in Figure 1, the present invention includes a small bevel gear 10 driven by power, the small bevel gear 10 drives two large bevel gears 1, 11 at the same time, and two sun gears 2 are coaxially arranged with the two large bevel gears 1, 11 , 12, each sun gear 2, 12 simultaneously drives a group of planetary gears 3, 4, 13, 14 (with every group of two planetary gears as an example, it can also be three planetary gears), and the upper group of planetary gears 3 The central axis of , 4 is connected with a planetary gear carrier 5, and planetary gear 3, 4 is meshed with the internal tooth of a ring gear 6 at the same time; The wheels 13 , 14 mesh with the internal teeth of a ring gear 16 . The central shafts of the two output gears 7, 17 are connected to the two planetary gear carriers 5, 15 respectively. The two output gears 7, 17 mesh ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com