Process for producing liquid crystal display device, spacer particle dispersion liquid, and liquid crystal display device

A technology of liquid crystal display devices and spacer particles, which is applied in nonlinear optics, instruments, optics, etc., can solve the problems of spacer particles that are difficult to fix, contain impurities, and have poor dispersion, and achieve the effect of improving configuration accuracy and good wetting

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1~13、 comparative example 1~3

[0297] (Preparation of spacer particle dispersion)

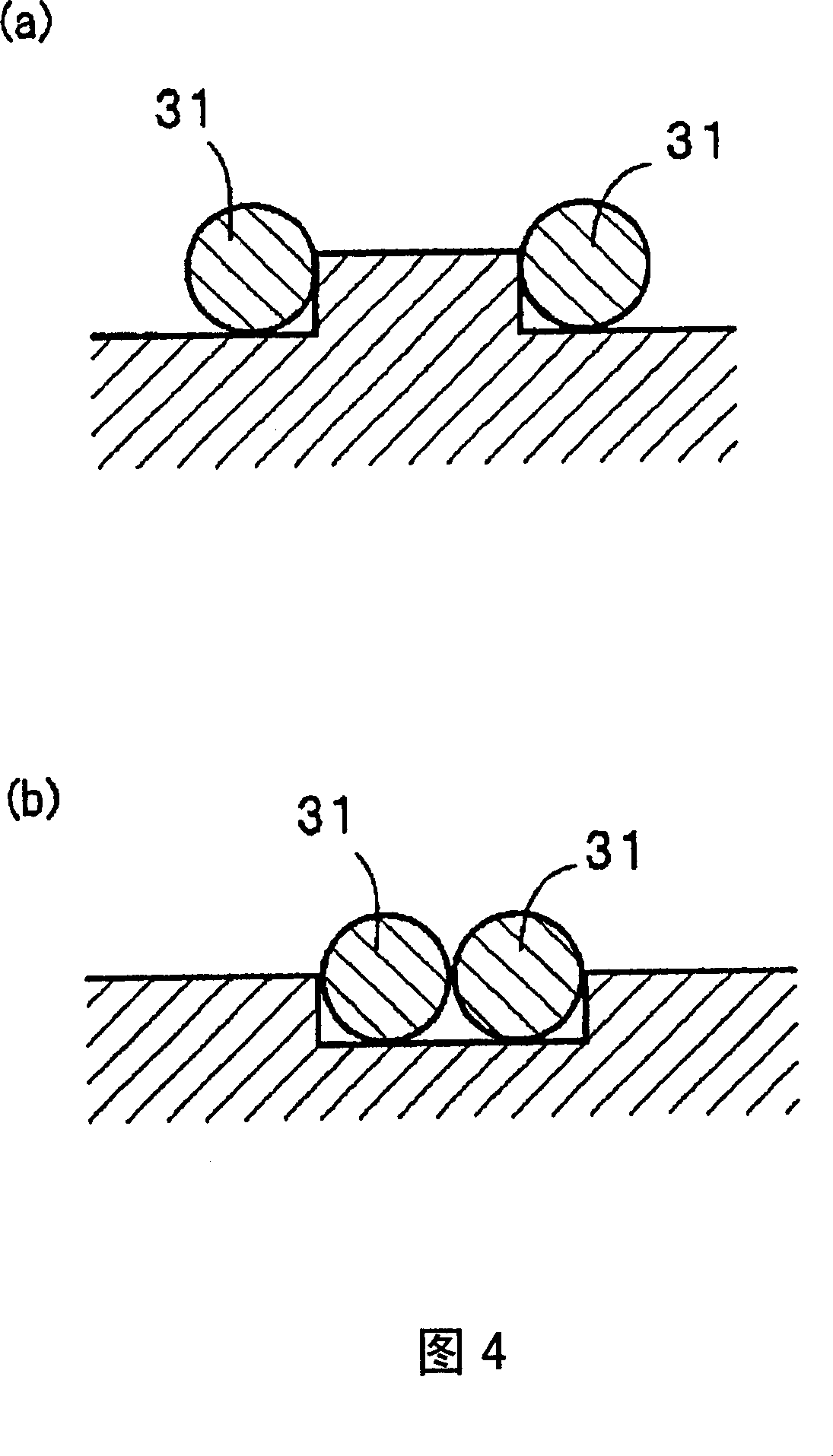

[0298] Take a necessary amount of spacer particles obtained by the method described above to reach a predetermined particle concentration, slowly add them to the solvent of the composition listed in Table 1 below, and stir sufficiently while using a sonicator, Spread it out. Thereafter, aggregates were removed by filtration through a stainless steel mesh having a mesh size of 10 μm, and spacer particle dispersions S1 to S8 were obtained. The surface tension of the obtained spacer particle dispersion was measured by the Wilhelmy method using a platinum plate. The results are shown in Table 1 below.

[0299] (production of substrate)

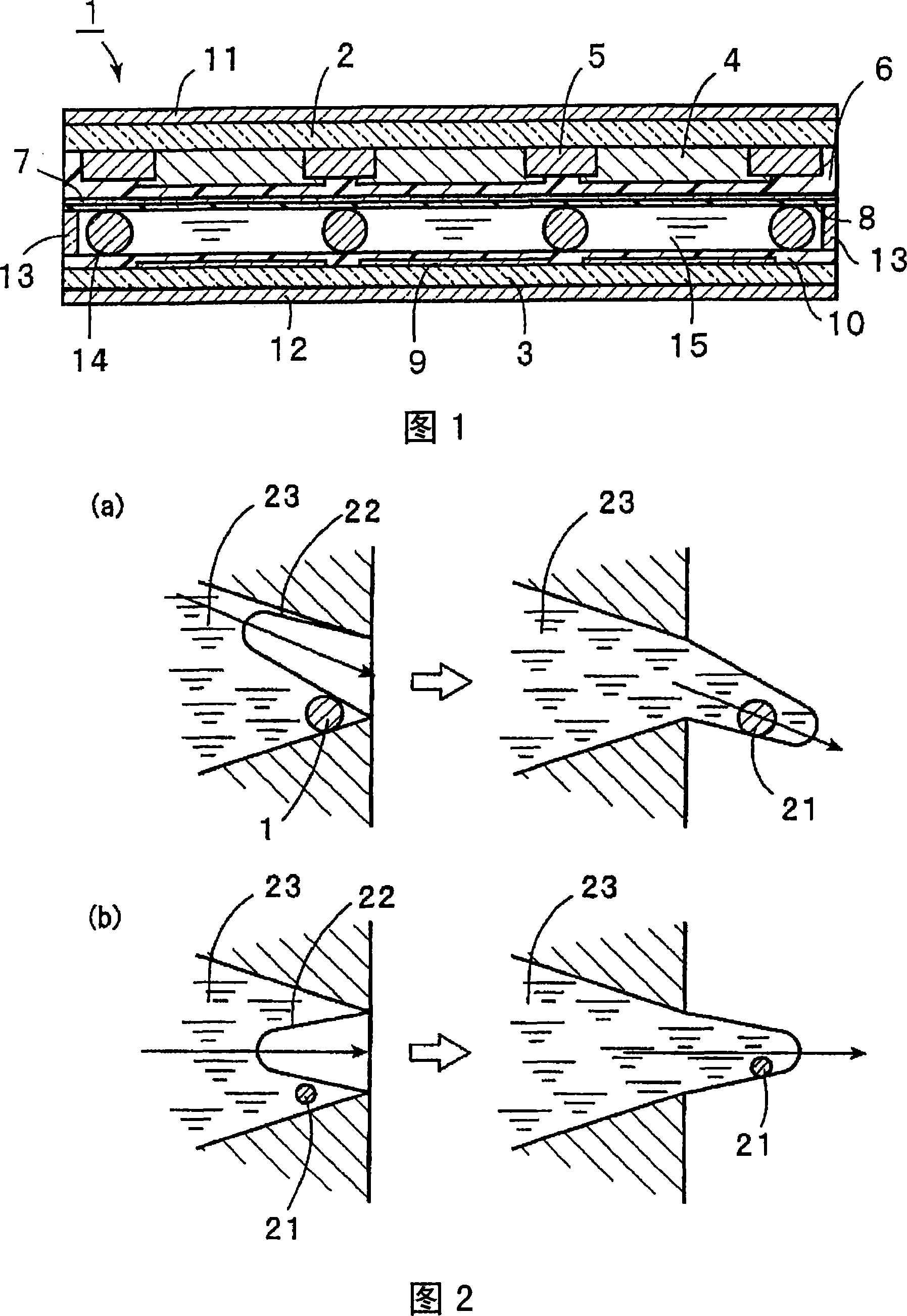

[0300] As the first substrate for the liquid crystal test panel, a color filter substrate was used, and as the second substrate, a liquid crystal display device substrate (TFT array dummy substrate) imitating the steps on the TFT array substrate was used.

[0301] (color filter substrate)

...

Embodiment 14~36

[0345] (Examples 14-36, Comparative Examples 4-14)

[0346] (Preparation of spacer particle dispersion)

[0347] Take the necessary amount of spacer particles obtained by the method to reach the specified particle concentration, slowly add to the solvent of the composition listed in the following Table 3 and Table 4, the same as in Example 1, etc., by adding It was dispersed while stirring well using a sonicator. Thereafter, aggregates were removed by filtration through a stainless steel mesh having a mesh size of 10 μm, and a spacer particle dispersion was obtained.

[0348] The surface tension at 20° C. of the obtained spacer particle dispersion was measured by the Wilhelmy method using a platinum plate. In addition, when the spacer particle dispersion liquid was introduced into a test tube with an inner diameter of φ5 mm until the height reached 10 cm and then left to stand, the time required for the accumulation of spacer particles at the bottom of the test tube could be...

Embodiment 37~46

[0398] (Examples 37-46, Comparative Examples 15-20)

[0399] (Preparation of spacer particle dispersion)

[0400] All the solvents used in the preparation of the spacer dispersion were grades used in the electronics industry. The preparation of the spacer particle dispersion was carried out in a clean room (Class 10000).

[0401] Take a necessary amount of spacer particles obtained by the method described above to reach a specified particle concentration, slowly add to the solvent of the composition listed in the following Tables 6 and 7, and fully Stir to disperse it. Thereafter, aggregates were removed by filtration through a stainless steel mesh having a mesh size of 10 μm, and a spacer particle dispersion was obtained.

[0402] Then, in Examples 37 to 46 shown in Table 6 below, the spacer particle dispersion was filtered with a filter having a filtration diameter through which the spacer particles could pass. Then, after centrifugation was performed to remove dust part...

PUM

| Property | Measurement | Unit |

|---|---|---|

| surface tension | aaaaa | aaaaa |

| surface tension | aaaaa | aaaaa |

| surface tension | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com