Oil product storage tank cleaning hydraulic type self-controlled robot

A robot and hydraulic technology, which is applied in the direction of manipulators, motor vehicles, cleaning hollow objects, etc., can solve the problems of unscientific cleaning process, non-recycling of sludge, time-consuming and labor-intensive cleaning, etc., to achieve convenient and fast assembly, compact structure, and prevent Effects of Environmental Pollution

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0028] In order to further disclose the technical solutions of the present invention, the following will be described in detail through examples in conjunction with the accompanying drawings:

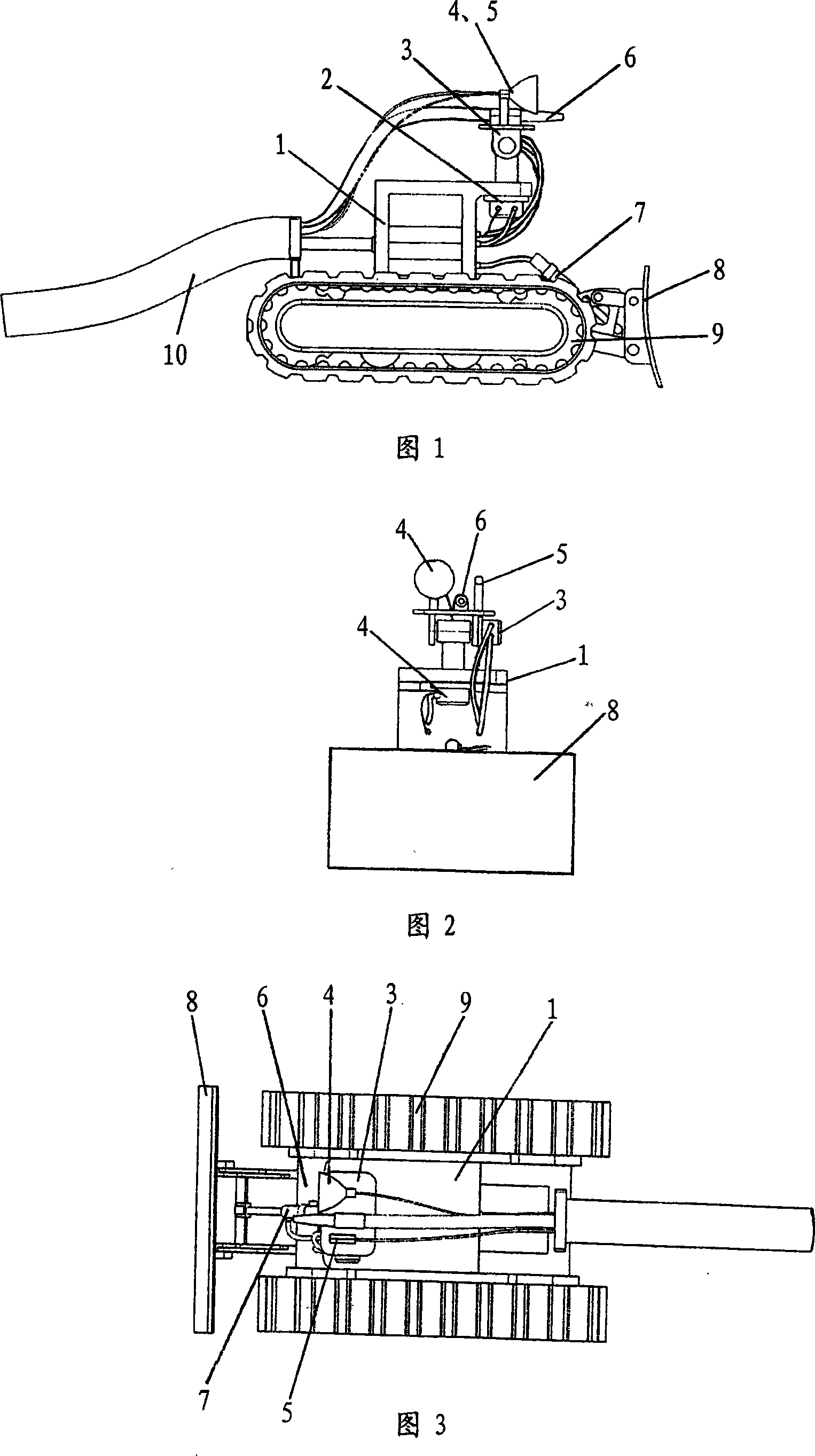

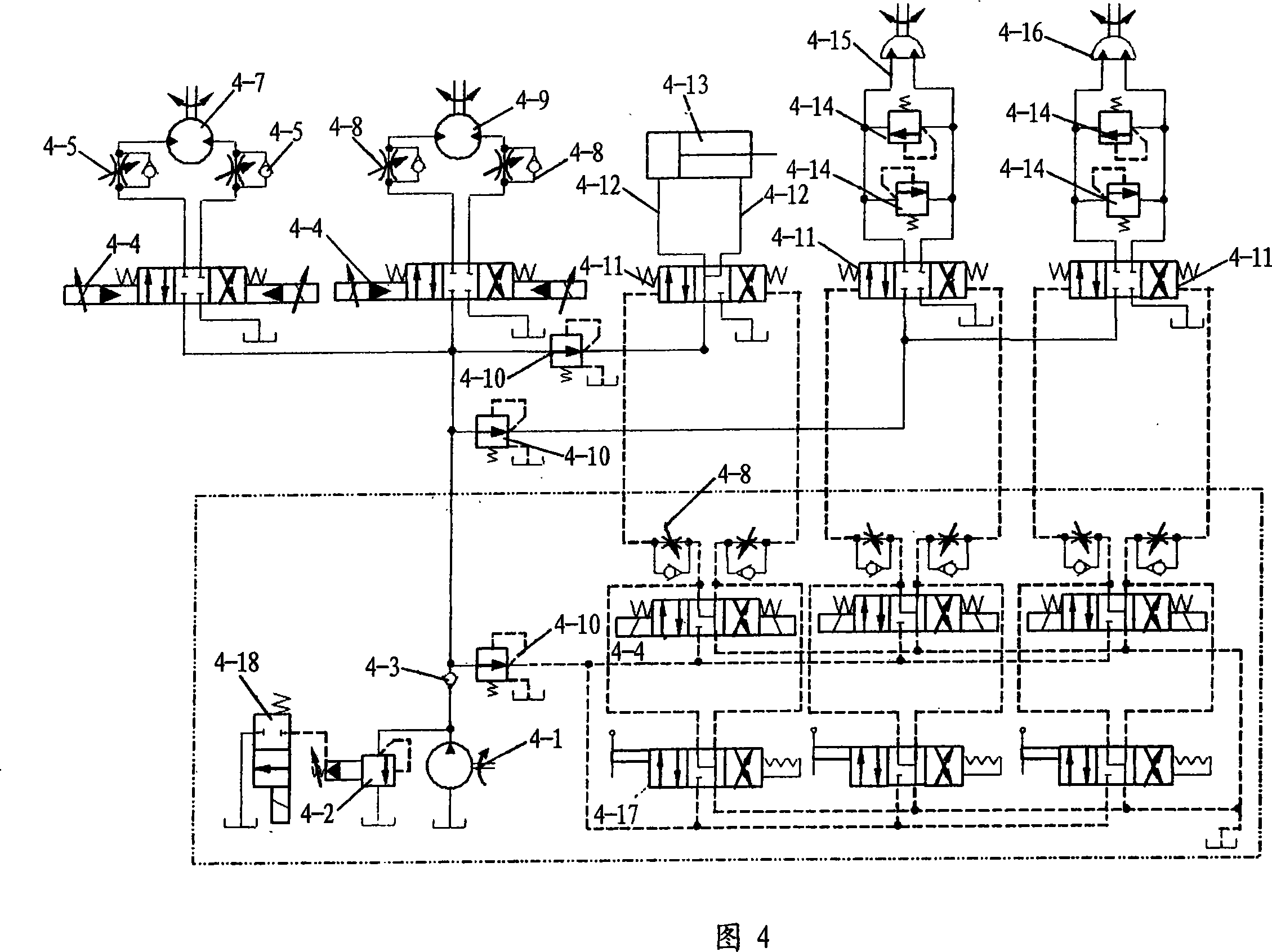

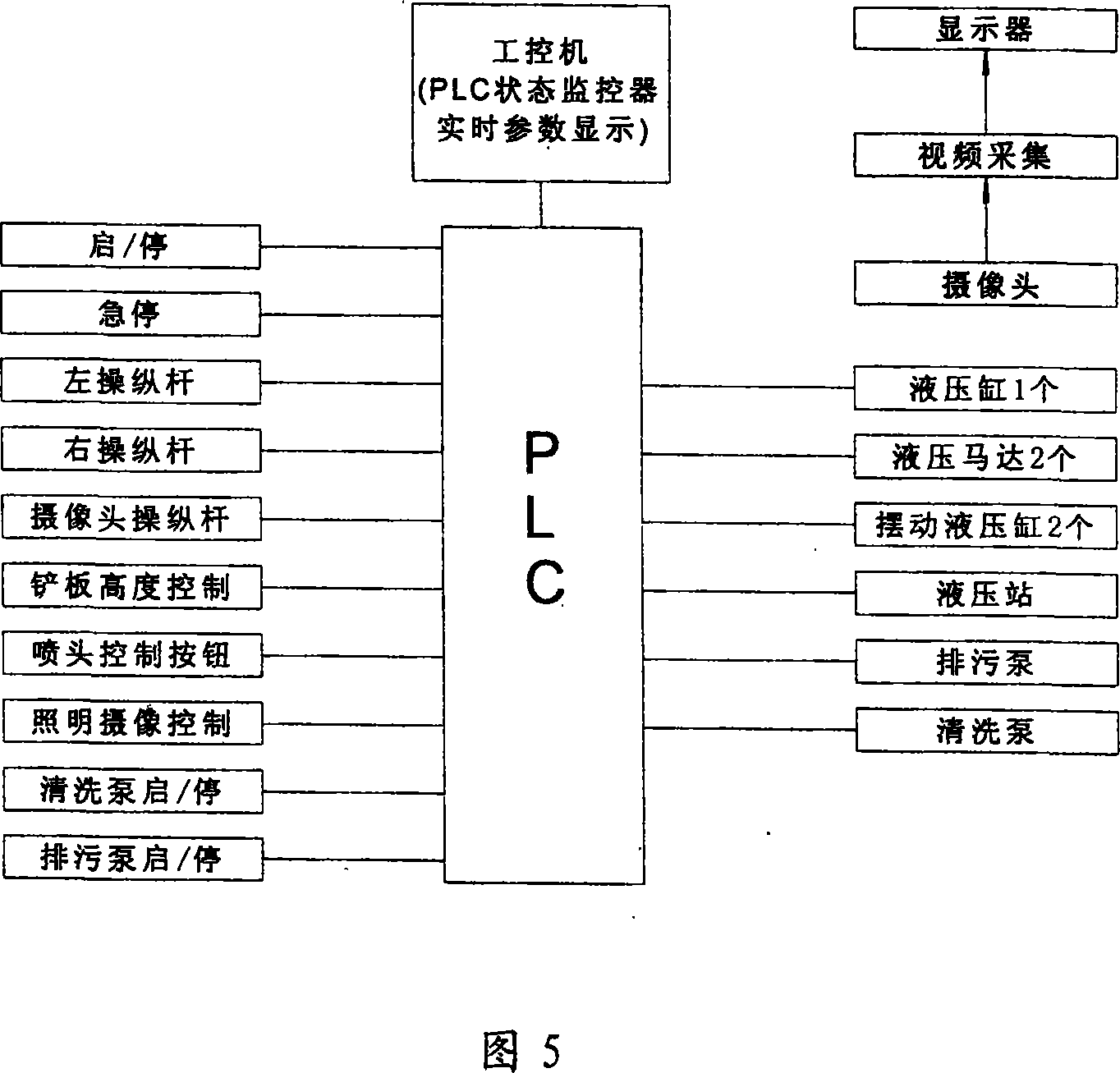

[0029] The invention consists of a robot, a hydraulic system, a control system and a sludge storage and treatment tank, and is characterized in that the robot includes a frame 1, a turntable 2 at the front of the upper end of the frame, and a pitch turntable 3 connected to the turntable shaft, which is parallel to the pitch turntable. The set searchlight 4, spray head 6 and camera 5, the hydraulic pipelines connected with the hydraulic swing cylinders of the two turntables and the spray head, are arranged on the front end of the lower part of the frame, which is connected with the frame shaft mechanism and connected with the hydraulic cylinder 7. The crawler mechanism 9 driven by hydraulic motors on both sides of the lower part of the frame, the hydraulic system includes hydraulic pumps ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com