Cross cramp for steel wire

A cross buckle and wire rope technology, applied in the direction of transmission elements or pulley ropes or cables, protective equipment, textile cables, etc., can solve problems such as wire rope damage, and achieve the effects of easy protection, low processing cost, and material saving

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

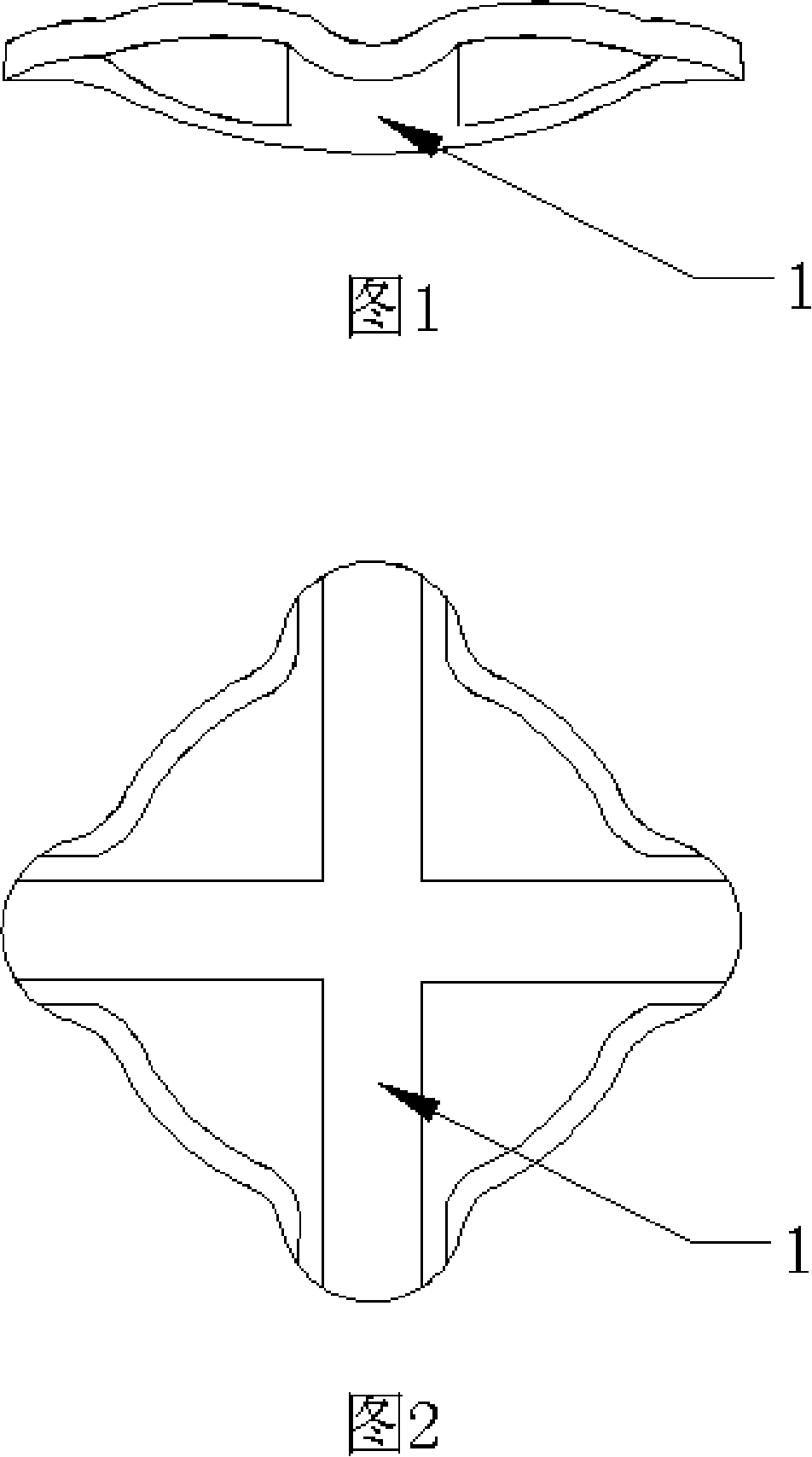

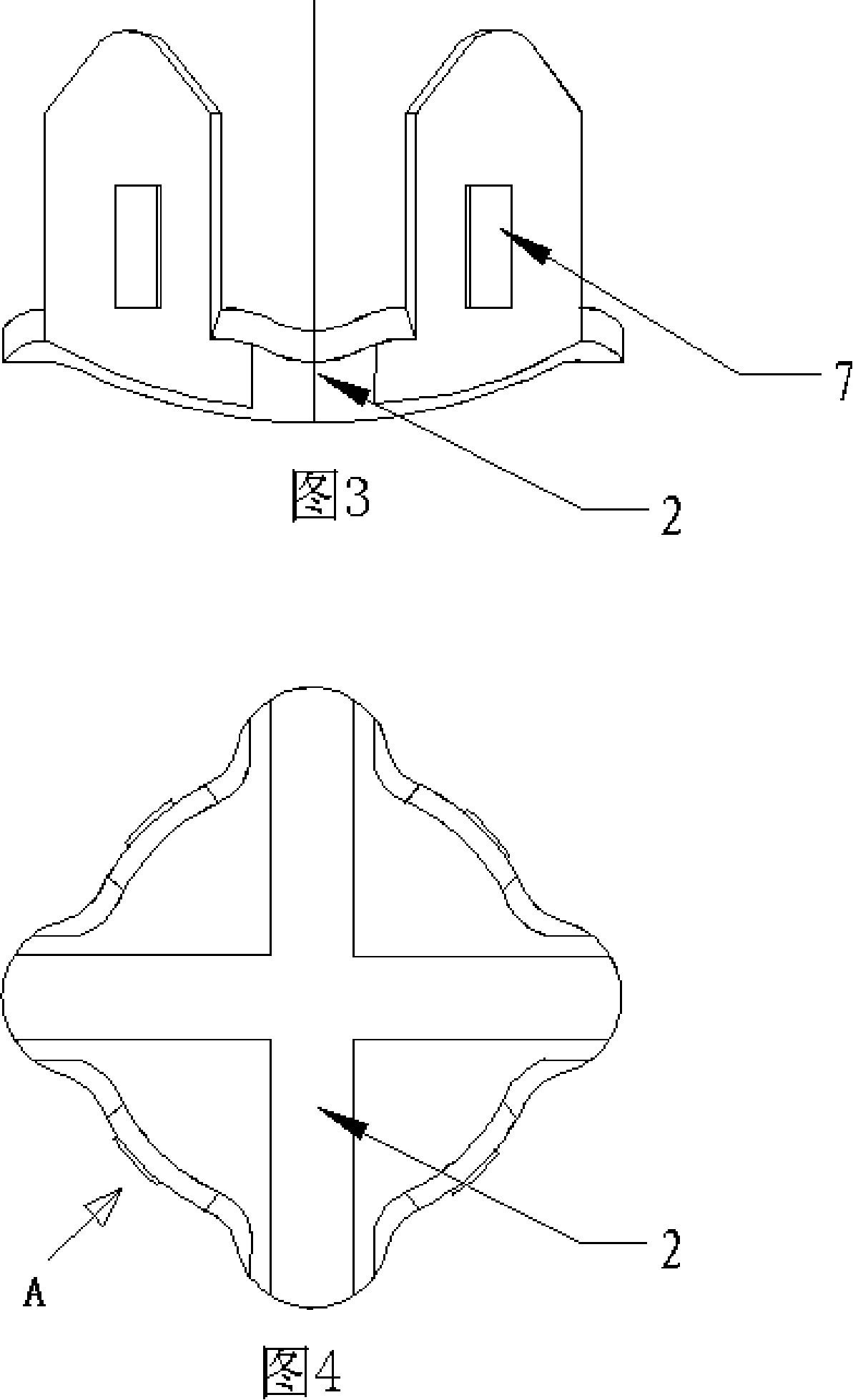

[0022] As shown in Fig. 1, Fig. 2, Fig. 3, Fig. 4 and Fig. 5, the steel wire rope cross buckle of the present invention includes an upper card 1 and a lower card 2, and four claws 3 are arranged on the bottom surface of the lower card 2. The bottom surfaces of the card 1 and the lower card 2 are concave arc-shaped bottom surfaces. Therefore, when the upper card 1 and the lower card 2 are fastened together, they have a hollow cavity shape with an upper convex and a lower concave. After the cross buckle is fastened with force, the intersection of the wire ropes still enjoys enough accommodation space between the cards. The pressing force of the upper and lower cards on the steel wire rope is reduced, and the intersection of the steel wire rope can be well protected.

[0023] In this way, the wire rope cross buckle can be fastened by pressing the four claws 3 of the lower card 2 on the upper card 1 with only one claw pressing tool.

Embodiment 2

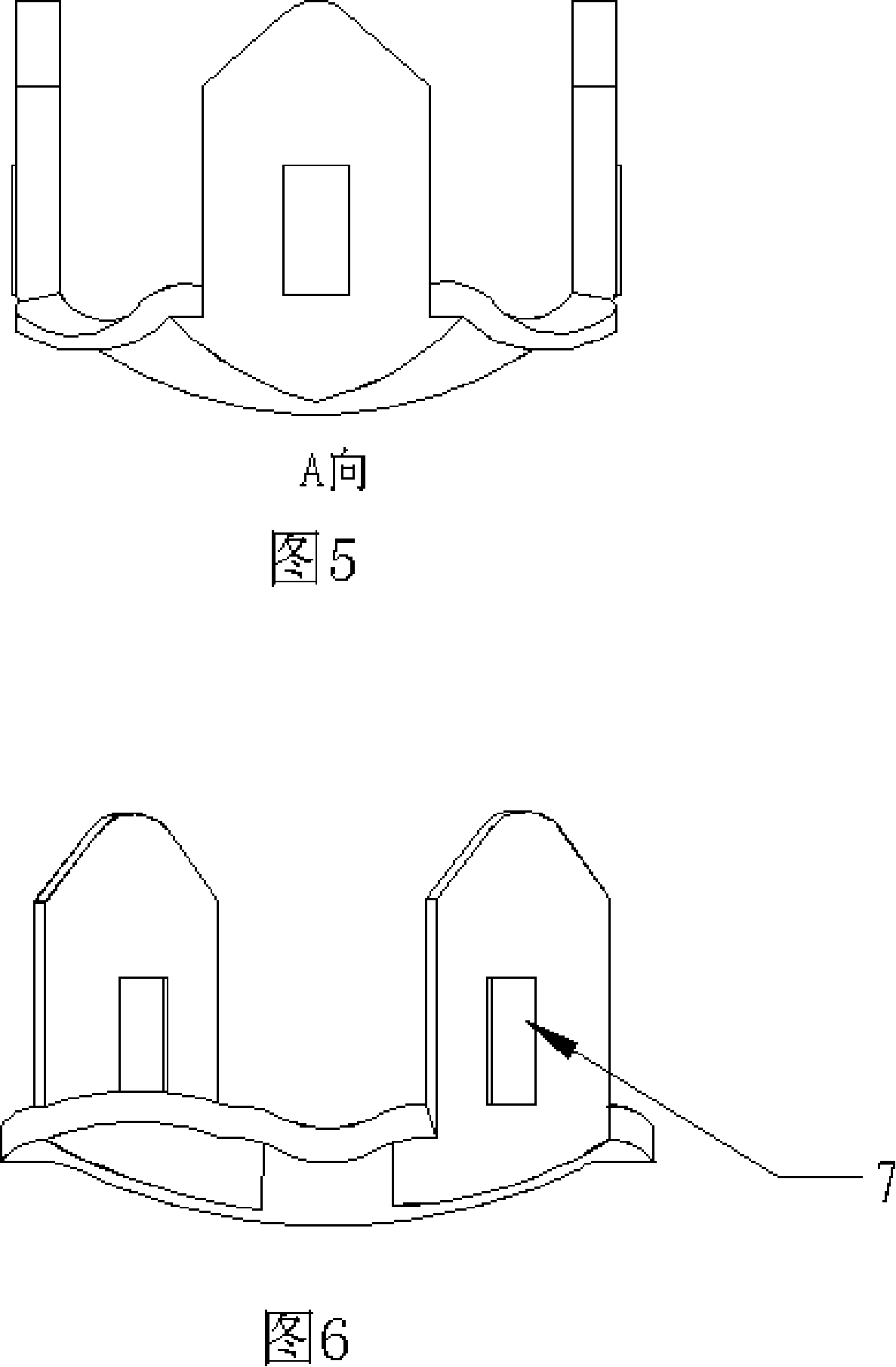

[0025] As shown in Fig. 6, Fig. 7 and Fig. 8, the bottom surfaces of the upper and lower cards are concave arc-shaped, and both have two claws 3 and can exchange positions.

[0026] At this time, the upper card 1 and the lower card 2 are interchangeable, and only one set of molds is required for processing, but after the fastening, it is necessary to use a claw tool twice to press the claws 3 on the upper card 1 and the lower card 2.

[0027] As shown in the figure, the upper card 1 and the lower card 2 are round in shape. When the peripheral shape of the upper card 1 and the lower card 2 is a regular shape of a circle or a square, it is easy to process, the force is reasonable and the claws are evenly arranged.

[0028] When the claw 3 has an arc shape suitable for the upper card 1 and the lower card 2 , it can fit the upper card 1 and the lower card 2 better.

[0029] When there is a strip-shaped convex shape on the outer surface of the joint between the upper card 1 and th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com