Integral wall plate digitalized composite shaping process based on bending and moving point heat source

A kind of integral wallboard and compound forming technology, applied in the direction of digital control, electrical program control, etc., can solve the problems such as the overall strength reduction of formed parts

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

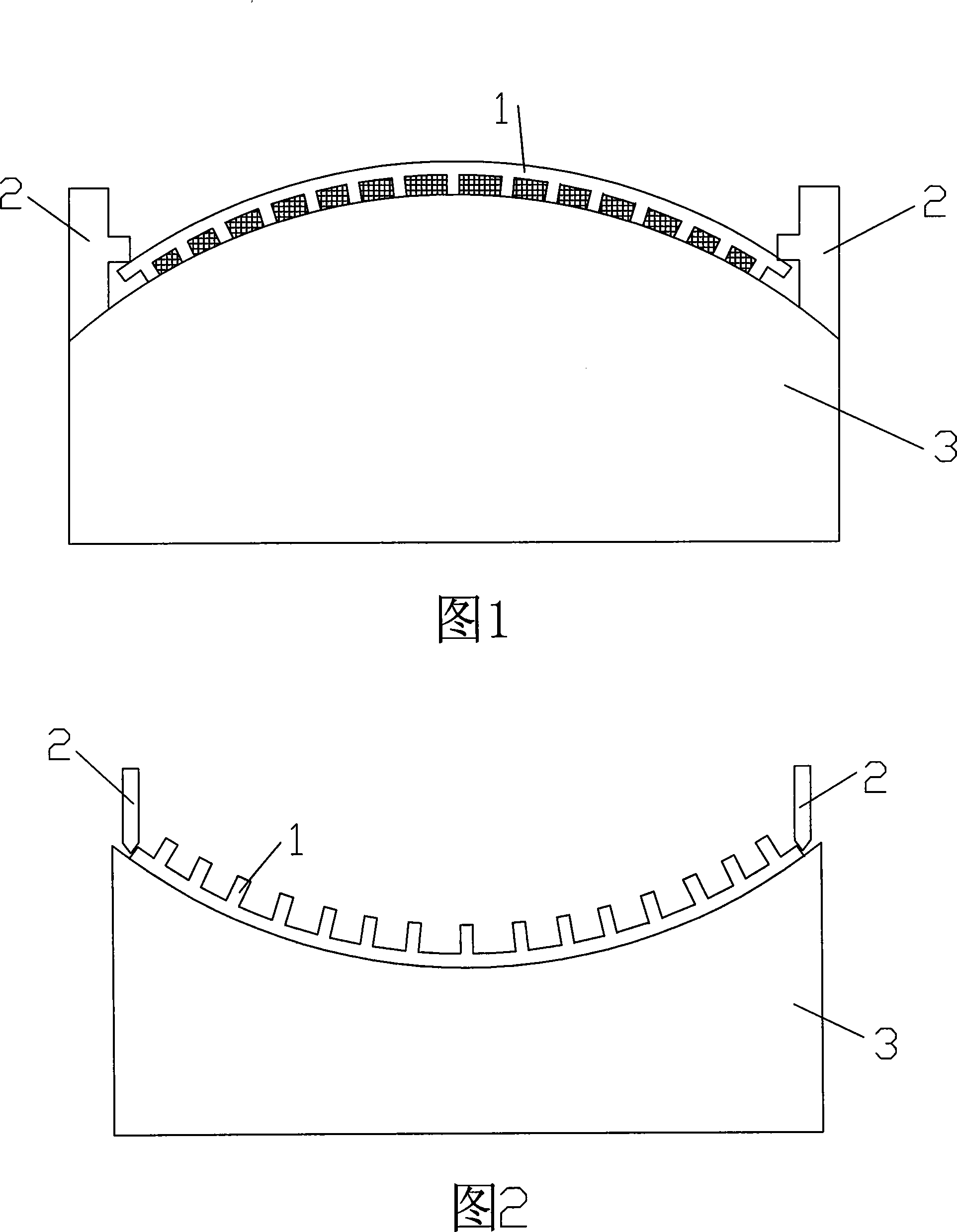

[0028] The present invention is specifically described below in conjunction with accompanying drawing and embodiment:

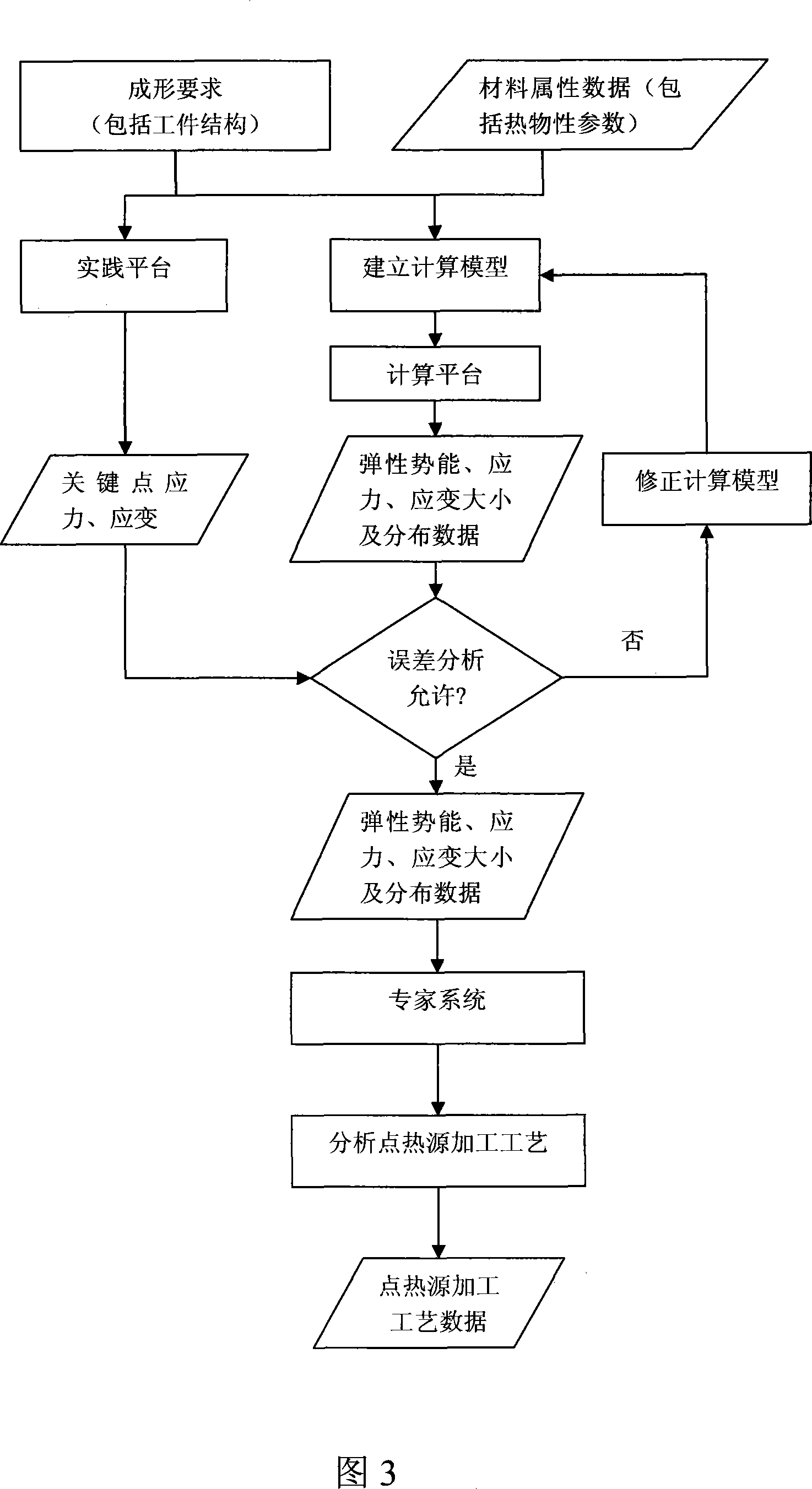

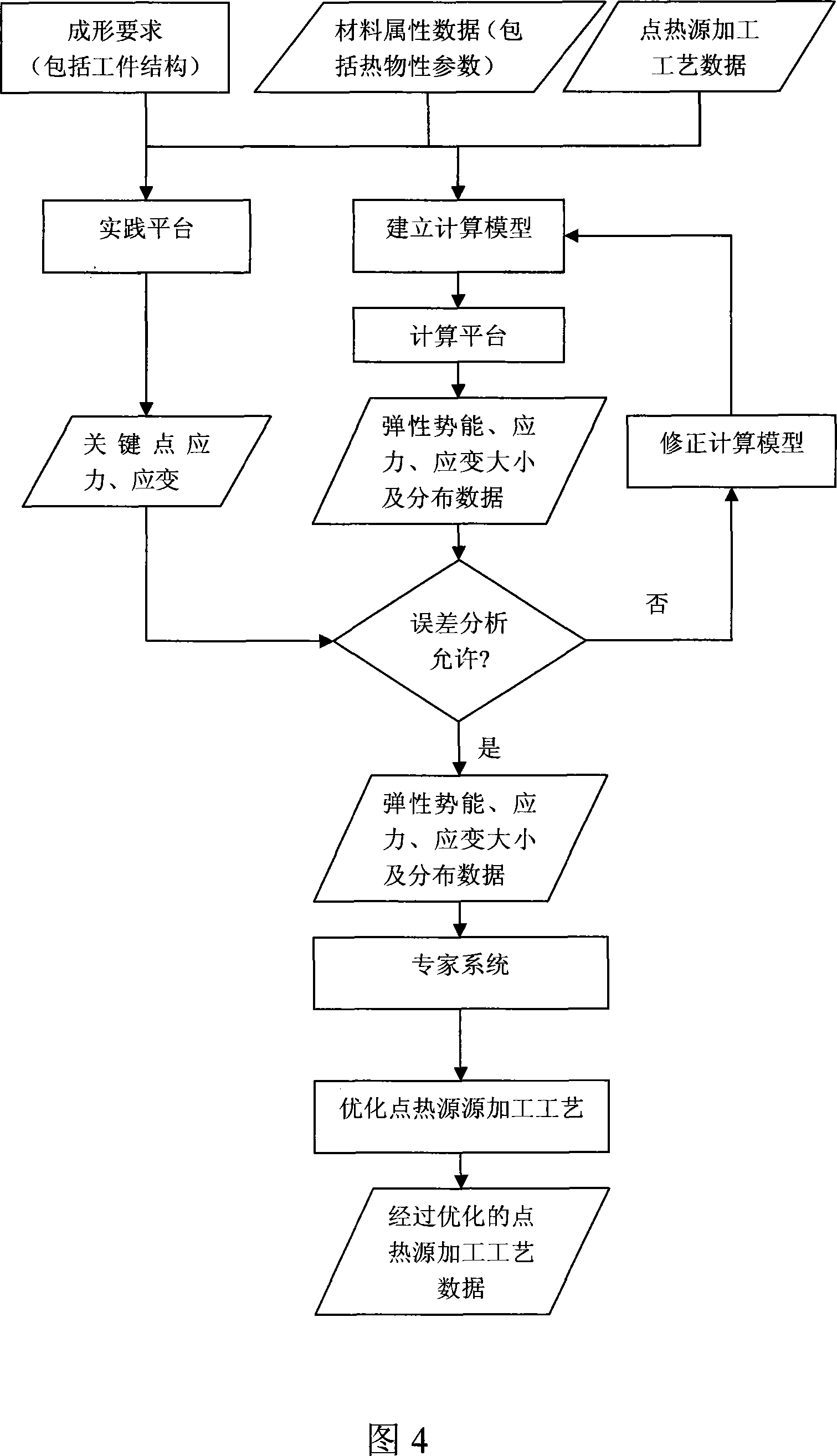

[0029] When the wall panel is bent and formed, the hard-to-deform area often corresponds to the local area where the elastic potential energy is relatively concentrated, and a moving point heat source with a certain intensity is introduced into this area in a certain way and path in a timely manner, and the deformation resistance of the material is reduced by building a local temperature field. And enhance its plastic deformation ability, promote the conversion of elastic potential energy into plastic deformation work, thereby improving the forming ability and forming accuracy of parts. The method can be divided into two working schemes: shaping and fine-tuning. The so-called forming scheme is to input a point heat source energy to the difficult-to-deform part of the part while forming by pressing or rolling. When this method is used for forming, the thermal...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com