Process and device for manufacturing printed products composed of a block of sheets and a cover

A technology for printed matter and book case, which is applied in the field of production and installation of printed matter composed of book block and book case, can solve the problems of maintaining the original order and the impossibility of book case, and achieves the effect of simple control technology

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

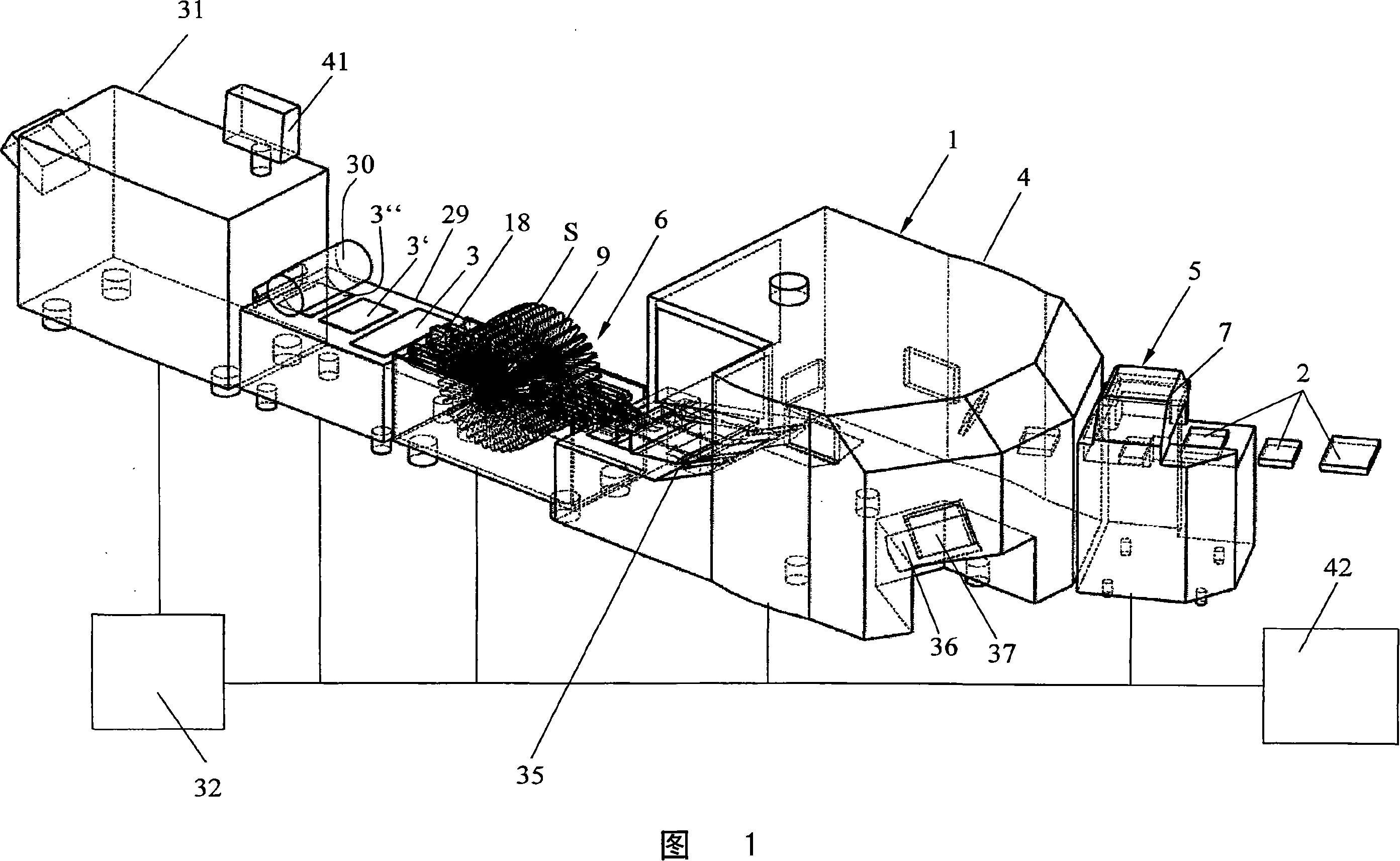

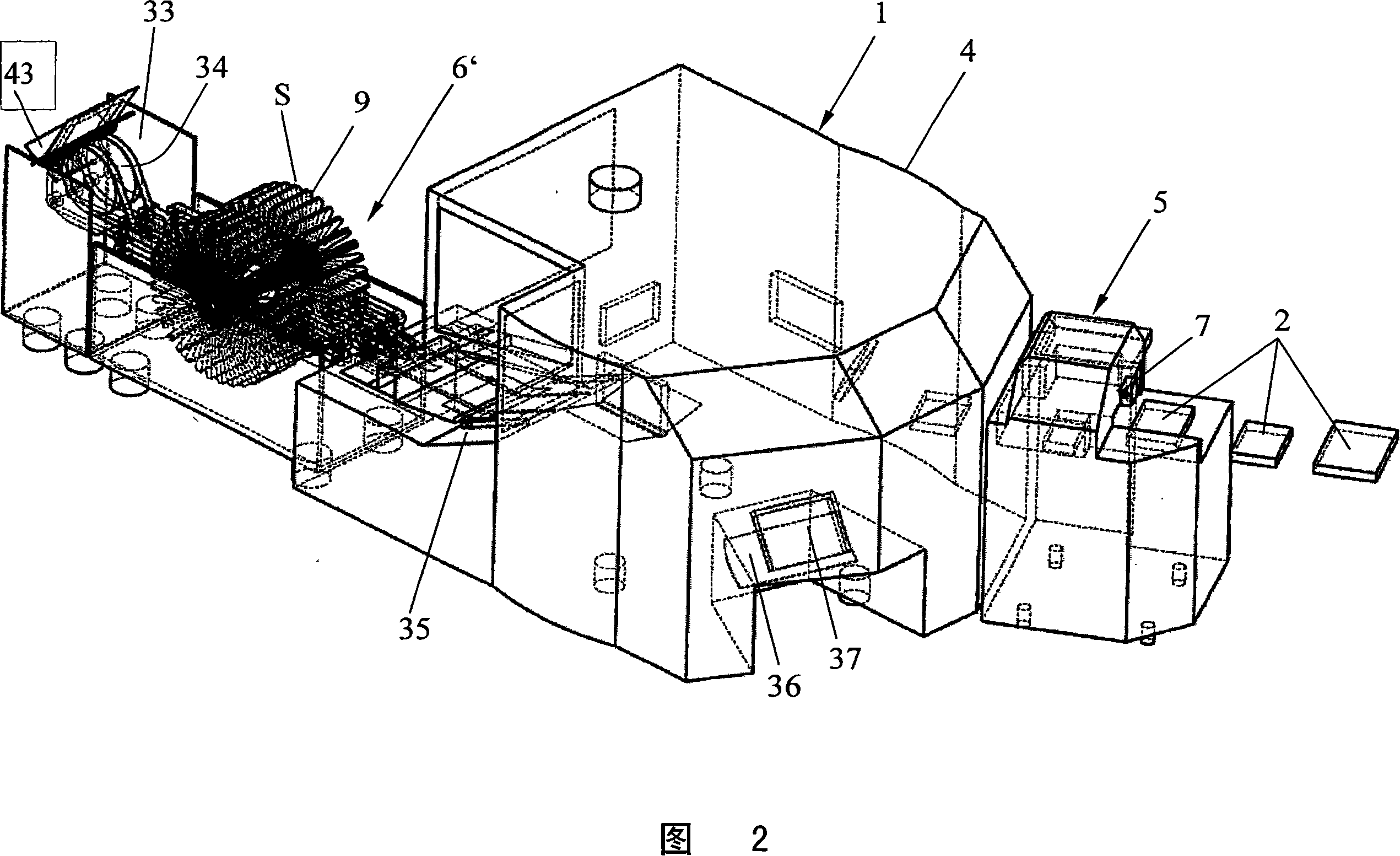

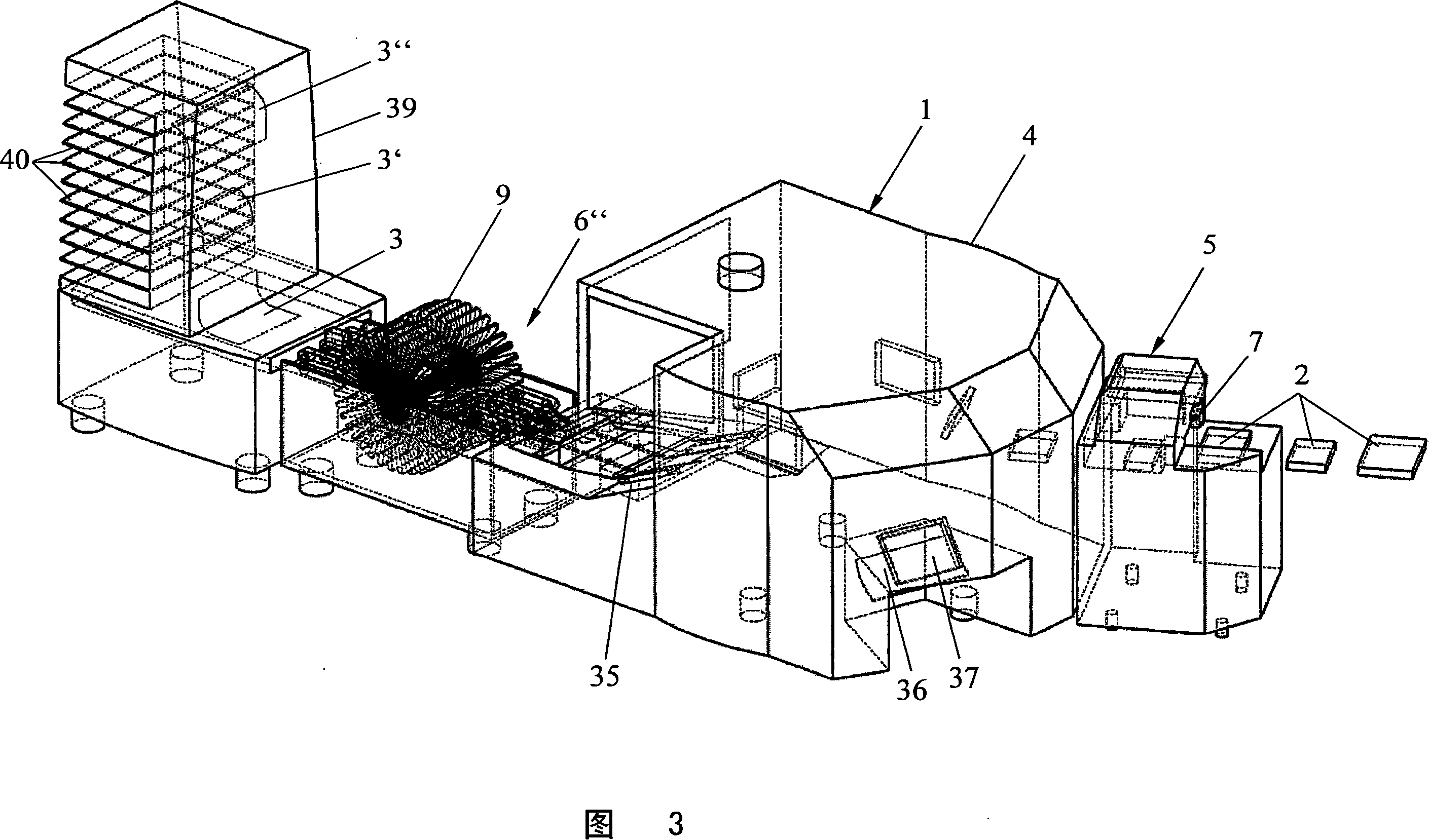

[0020] The device 1 shown in FIG. 1 has a processing device 4, in particular a perfect binder such as proposed in EP 1199187A, which can consist of a rotary table, but can also be of another type, for example with a linear Arranged multi-station. In this processing device 4 a book block 2 is always assigned a book case 3 . The book block 2 is produced in a book block printing machine 42 which is only schematically shown here. The book block printing machine 42 is preferably a digital printing machine with which printed products 2 can be produced sequentially. The latter book block 2 may differ both in its content and in its format. These book blocks 2 can be produced in the book block printing press 42 in small and very small runs and single prints.

[0021] The book block 2 is fed into the processing device 4 at the first input station 5 . The input is done with a conventional transport device not shown here, for example a conveyor belt. The first input station 5 has a r...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com