Mounting device for electrical component

A technology for mounting devices and electrical components, which is applied in the direction of electrical components, electrical components, and electrical components to assemble printed circuits, etc., which can solve problems such as increased misalignment, inability to fully ensure the reliability of the initial on-resistance connection, and misalignment of the IC chip substrate , to achieve the effect of preventing positional misalignment

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0038] Hereinafter, embodiments of an electrical component mounting device according to the present invention will be described in detail with reference to the drawings.

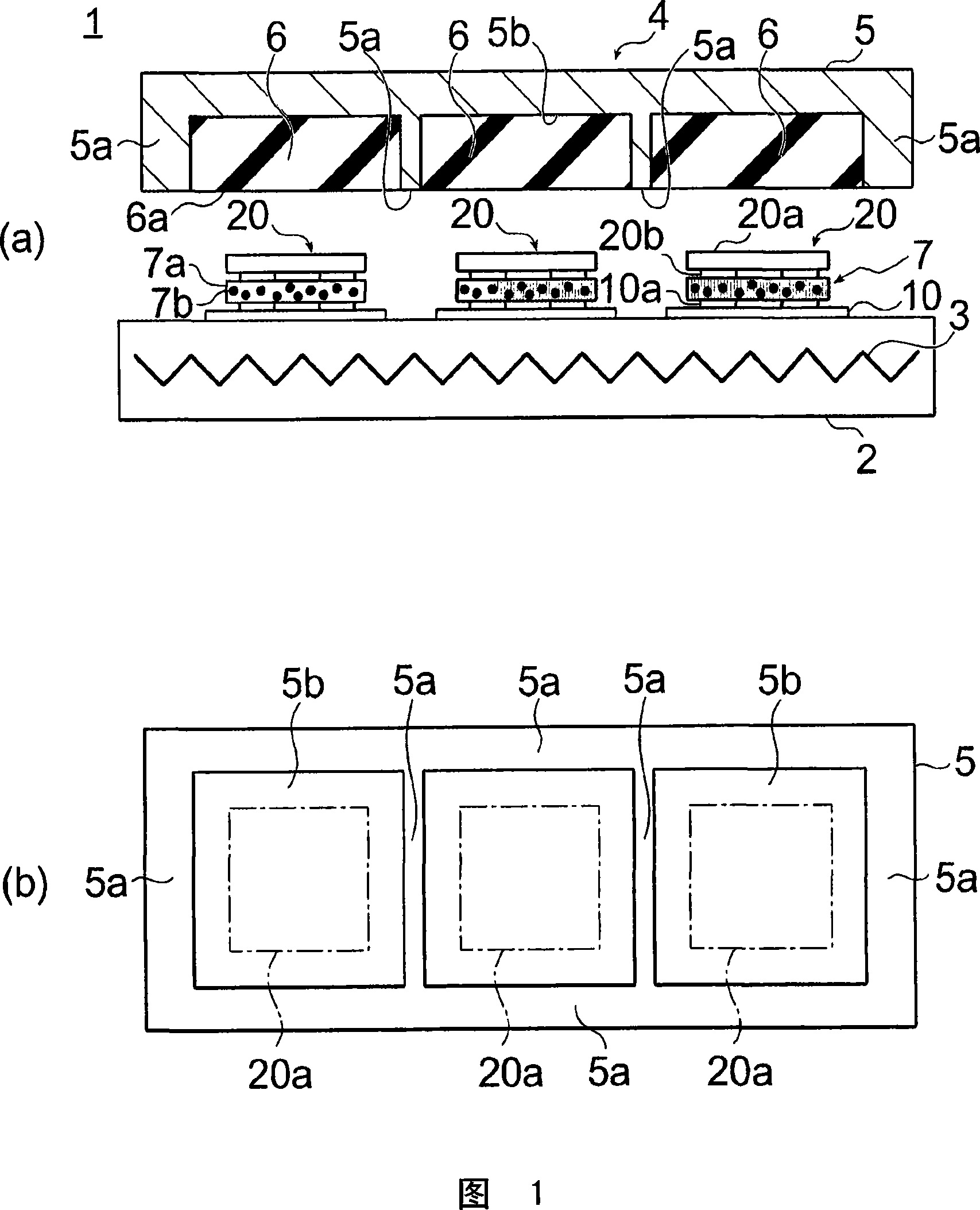

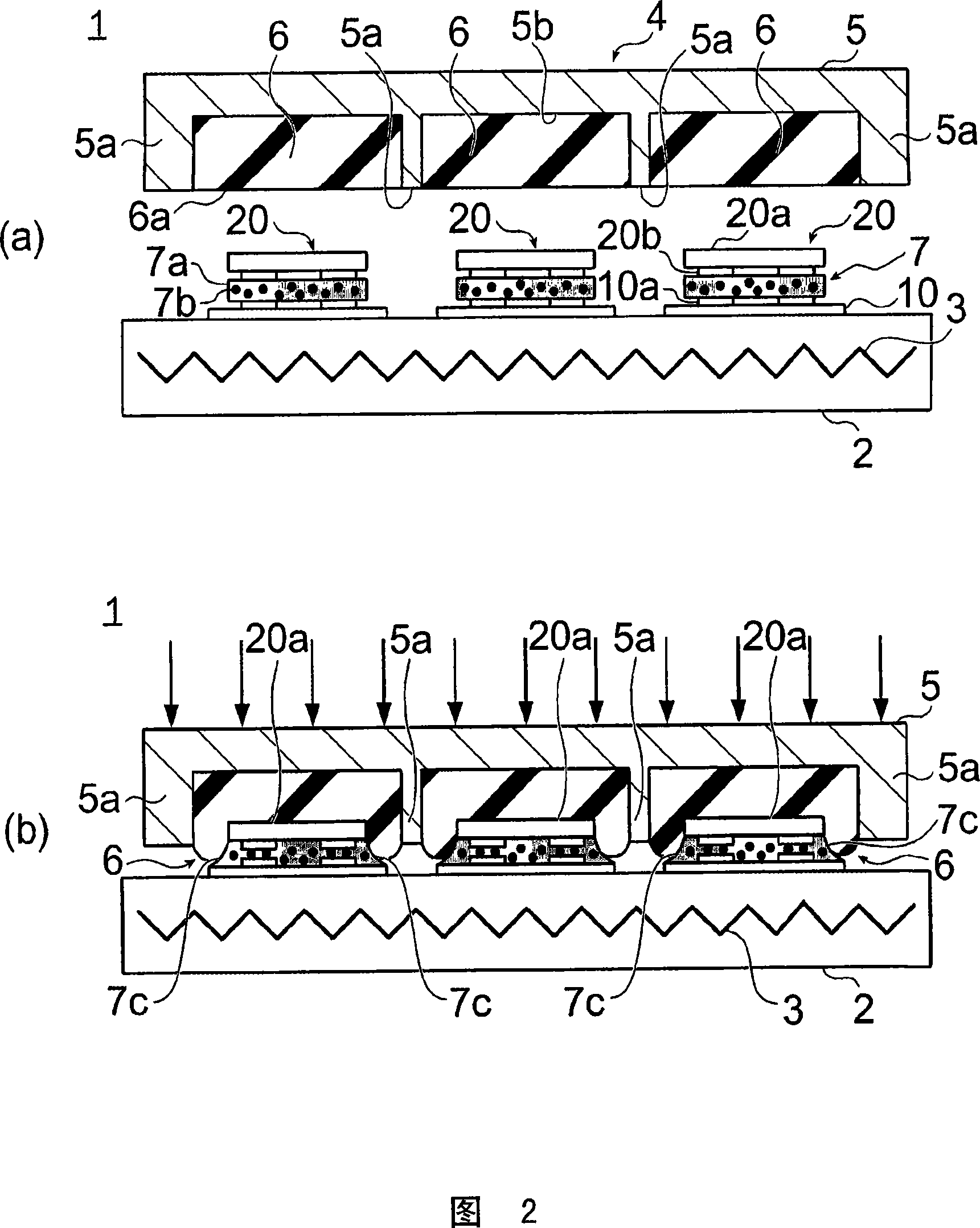

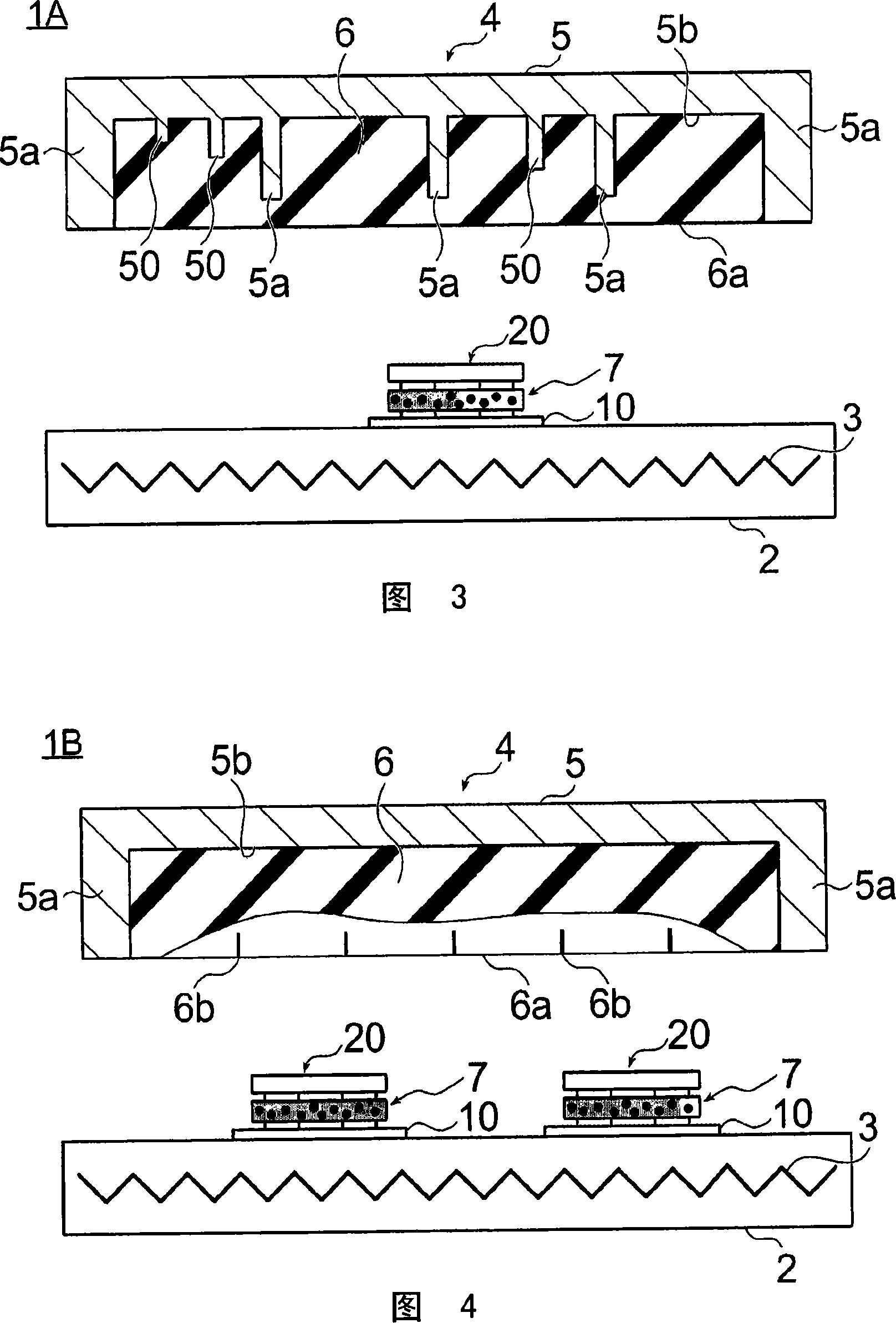

[0039] FIG. 1( a ) is a schematic configuration diagram showing a main part of a mounting device according to this embodiment, and FIG. 1( b ) is an explanatory diagram showing a positional relationship between a thermocompression joint and an IC chip of the mounting device.

[0040] As shown in FIG. 1(a) and FIG. 1(b), the mounting device 1 of this embodiment includes: a base 2 on which a wiring substrate 10 on which a wiring pattern 10a is formed is placed; and a base 2 on which a bump 20b is provided. The thermocompression joint 4 that pressurizes and heats the IC chip (electrical component) 20 .

[0041] Here, the base 2 is made of a predetermined metal, and a heater 3 for heating is provided inside it.

[0042] On the other hand, the thermocompression head 4 has a head body 5 made of a predetermined me...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com