Ozone generator

An ozone generator and isolator technology, applied in ozone preparation and other directions, can solve problems such as components failing to work

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

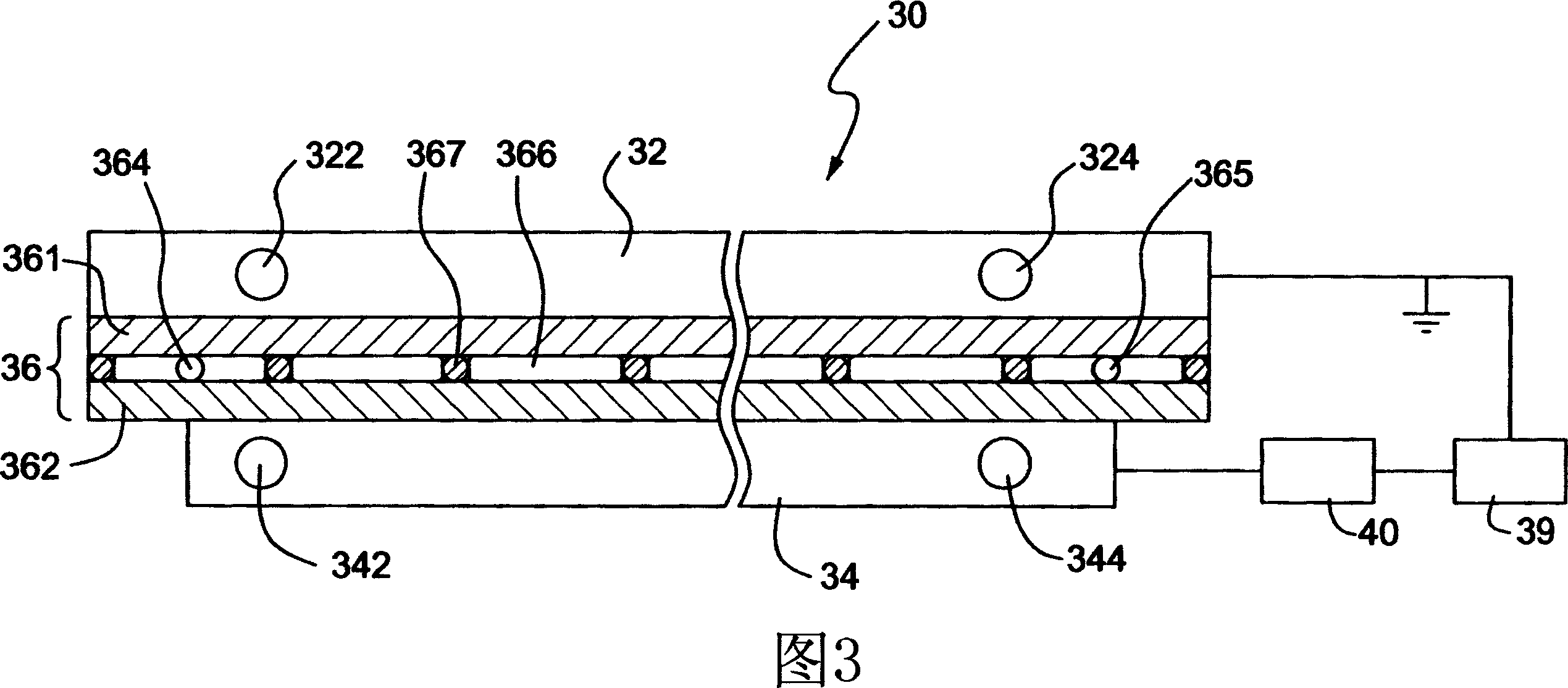

[0021] Fig. 3 illustrates a cross-sectional view of the structure of an ozone generator according to a first preferred embodiment of the present invention. As shown in FIG. 3 , the ozone generator 30 includes a cooling plate 32 , a high voltage plate 34 and a channel structure 36 . A cooling plate 32 is positioned opposite the high voltage plate 34 and a channel structure 36 is arranged between the two plates 32 and 34 . The high voltage plate 34 is further electrically connected to a power source 39 and a transformer 40, and the cooling plate 32 may be grounded. In addition, the cooling plate 32 may be a hollow plate including a hollow portion for filling coolant, and the openings 322 and 324 communicate with the hollow portion to allow the coolant to flow in and out. Similarly, the high voltage plate 34 may be a hollow plate that includes a hollow portion for filling with coolant, and openings 342 and 344 communicate with the hollow portion for coolant to flow in and out. ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com