Highly-water-soluble thermosetting phenolic resin and method for synthesizing the same

A technology of phenolic resin and synthesis method, which is applied in the field of resin synthesis, can solve problems such as inconvenient use and short storage period, and achieve the effects of prolonging storage period, improving performance and market competitiveness

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

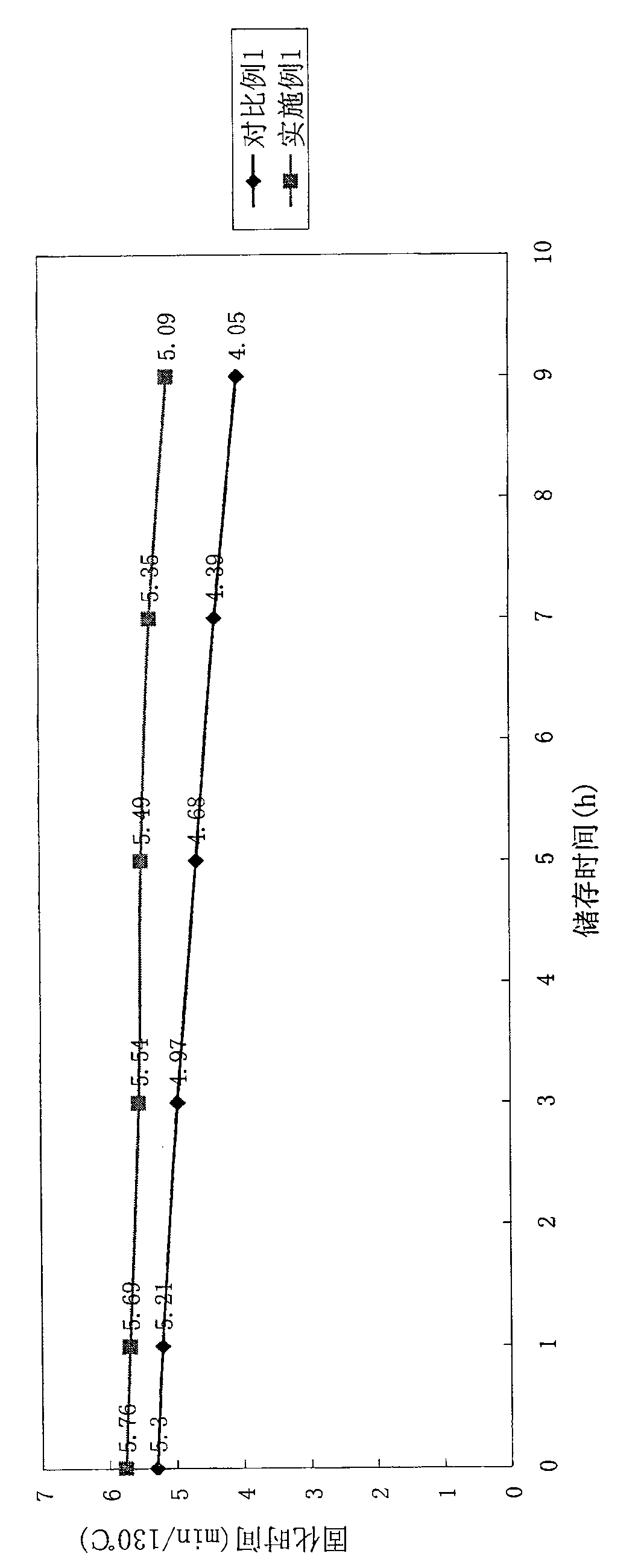

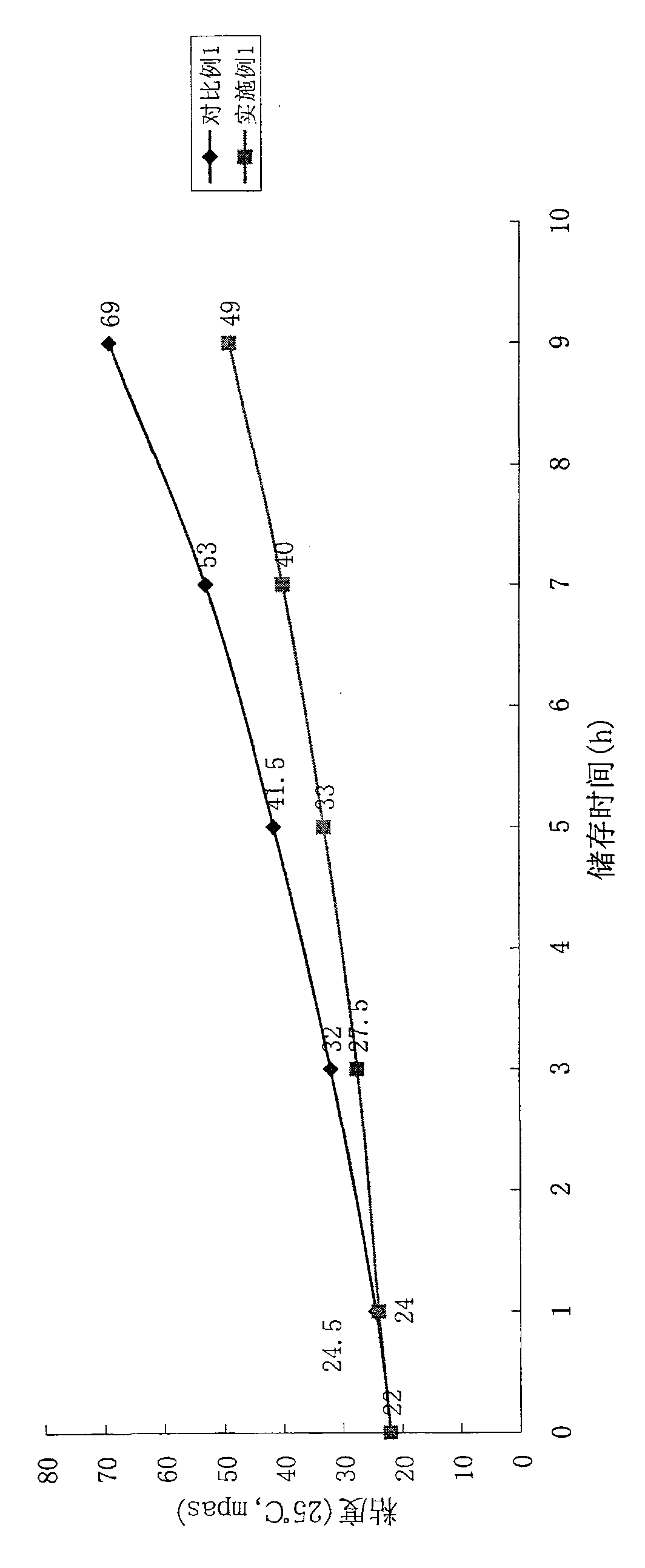

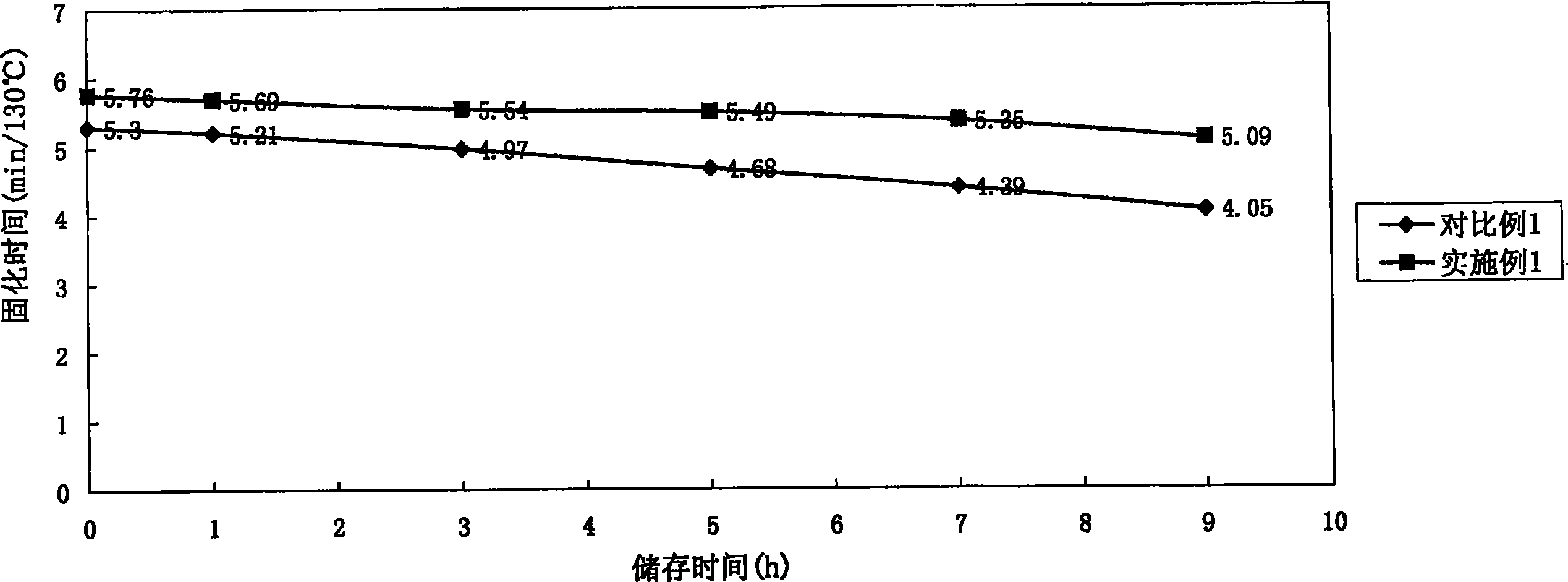

Embodiment 1

[0010] Add 90g of water, 38g of sodium sulfite, and 60g (37%) of formaldehyde into a 2000ml reactor, stir at room temperature for 40min, add 11.2g of sodium hydroxide (47%), and 376g of phenol; heat up and reflux for 60min, then cool down to 60°C, and add formaldehyde 748g (37%), heat up to 80°C for constant temperature reaction, and control the curing time at 5-7min / 130°C. Immediately lower the temperature to below 40°C and discharge to make a thermosetting resin.

Embodiment 2

[0012] In 2000ml reactor, add 90g water, 22g sodium sulfite, 18g sodium bisulfite, 67g (37%) formaldehyde, stir 40min at normal temperature, add sodium hydroxide 21g (47%), phenol 420g, heat up and reflux after 50min and cool down to At 60°C, add 845g (37%) of formaldehyde, raise the temperature to 80°C for constant temperature reaction, and control the curing time at 5-7min / 130°C. Immediately lower the temperature to below 40°C and discharge to make a thermosetting resin.

Embodiment 3

[0014] Add 90g of water, 52g of sodium metabisulfite, and 75g (37%) of formaldehyde into a 2000ml reactor, stir at room temperature for 60min, add 21g of sodium hydroxide (47%), 420g of phenol, heat up and reflux for 50min, then cool down to 60°C, add formaldehyde 809g (37%), heat up to 80°C for constant temperature reaction, and control the curing time at 5-7min / 130°C. Immediately lower the temperature to below 40°C and discharge to make a thermosetting resin.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com