Disc carrier for friction clutch

A friction clutch, disc technology, applied in the direction of friction clutch, clutch, mechanical drive clutch, etc., can solve the problems of high tool cost, high cost, time-consuming, etc., and achieve the effect of reduced manufacturing cost, rapidity, cost, and low cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

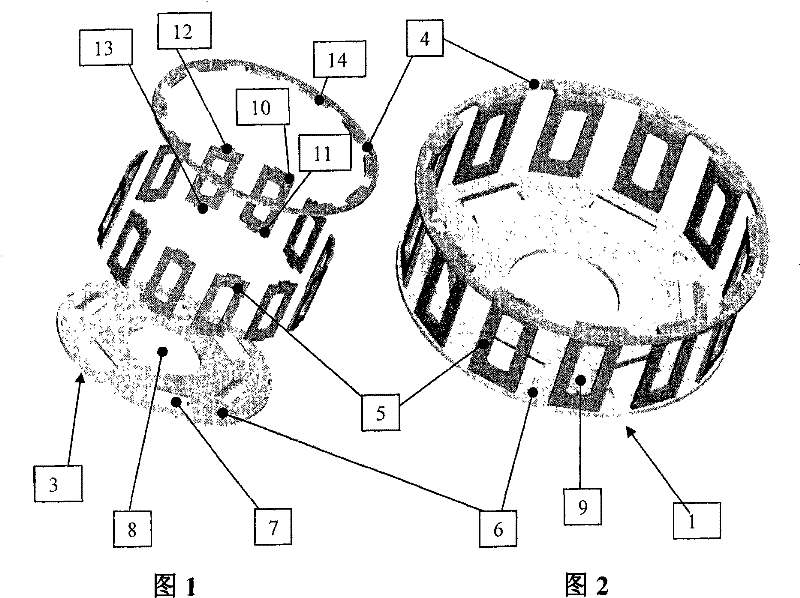

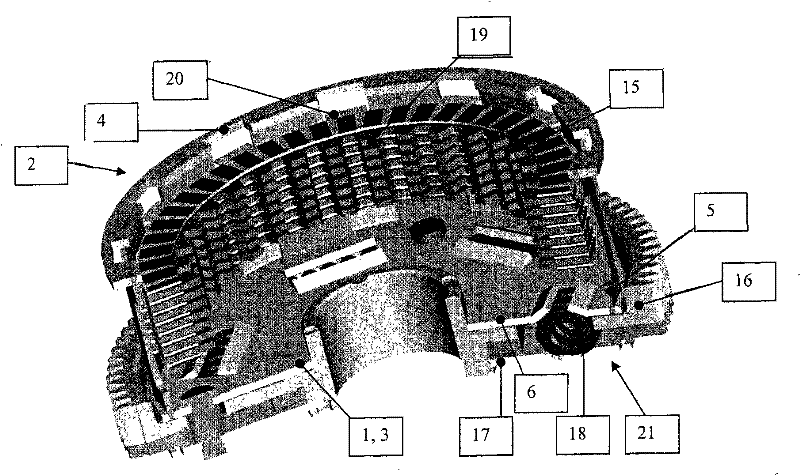

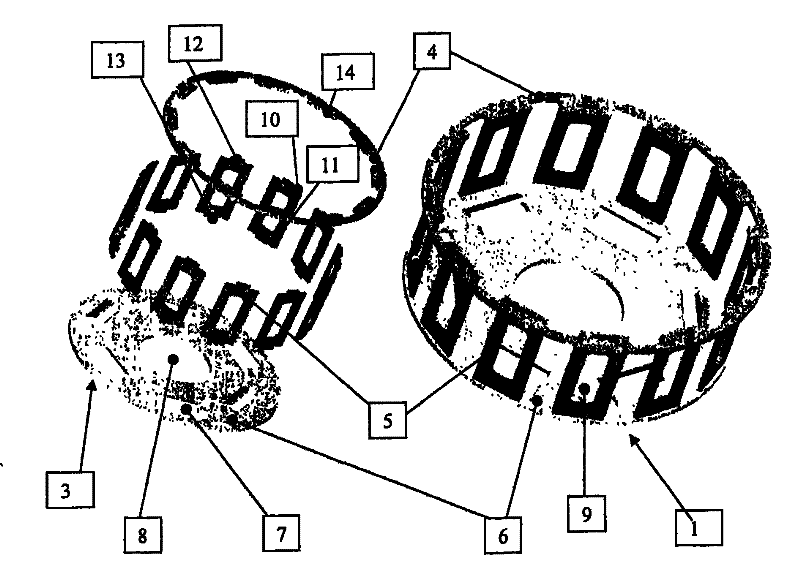

[0045] according to figure 1 and figure 2 Analysis, the structure of disc carrier 1 of the present invention and its modular standard assembly 3 (shown in figure 1 ) will become clear. according to figure 1 , the standard assembly 3 includes a circular retaining ring 4 and a base plate 6 in the example. Such as figure 1 As shown, in the example, a plurality of webs (webs) are arranged between elements 4 and 5, all webs have the same structure, in figure 1 Two meshes are indicated with reference numeral 5 in . In the example, twelve meshes are used, each constructed in the form of a frame and a rectangle with a rectangular central depression 9, as figure 1 as detailed in .

[0046] Tabs 12 and 13 are arranged on the respective narrow sides 10 and 11 of the web 5, in the illustrated embodiment the web 5 with the tabs forming a flat plate member. The protrusions 12 and 13 are used to fix the mesh to the retaining ring 4 and the base plate 6 respectively.

[0047] The re...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com