Shorting or breaking circuit testing method of polyalcohol flexible packing

A testing method and flexible packaging technology, applied in the direction of measuring electricity, measuring devices, measuring electrical variables, etc., can solve problems such as battery leakage and swelling, and achieve the effect of ensuring reliability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

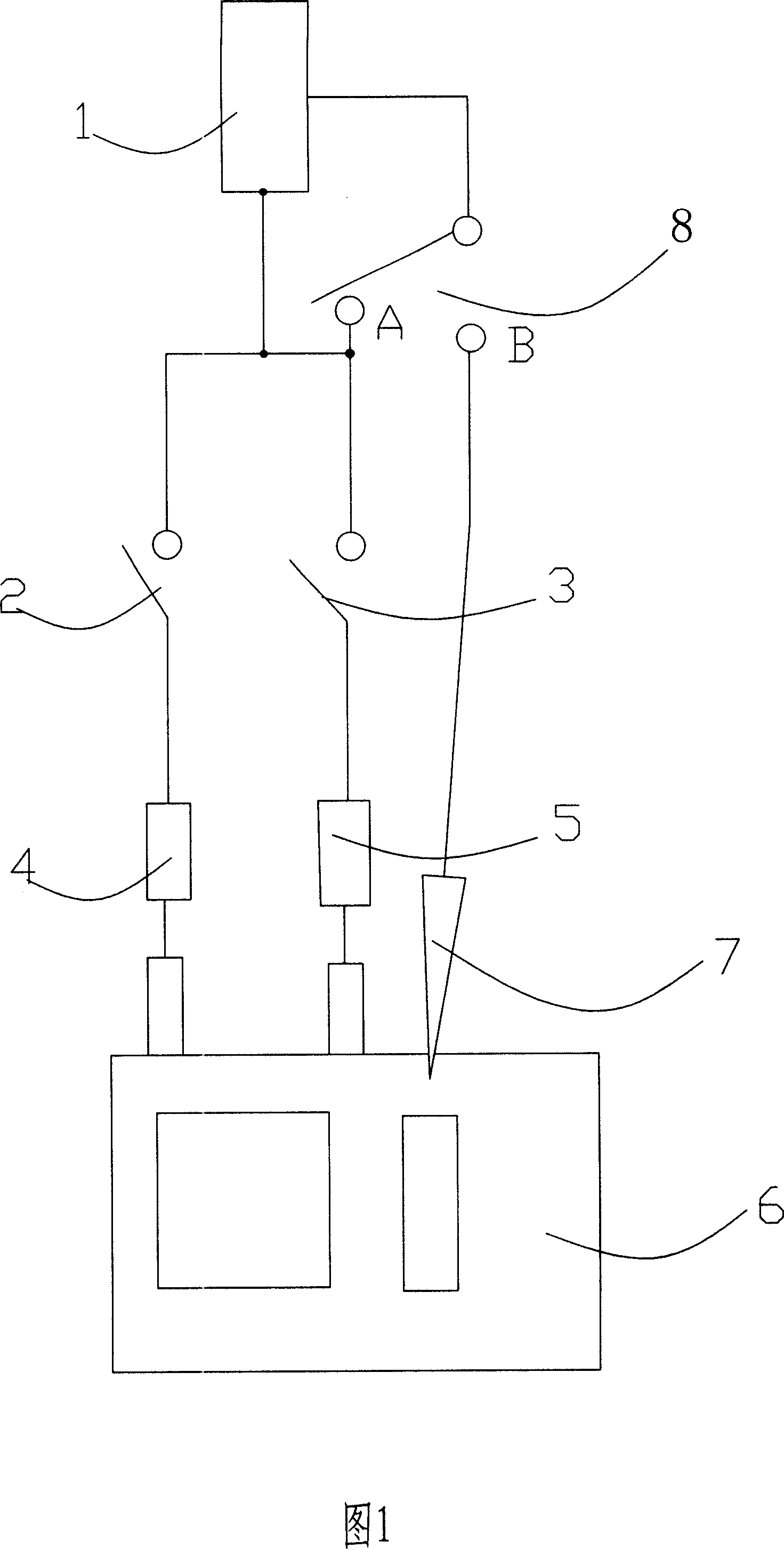

[0011] Please refer to shown in Fig. 1, below in conjunction with embodiment description a kind of short circuit, open circuit test method of polymer flexible packaging provided by the present invention, its technological process: first prepare a short circuit, open circuit tester 1, then to this instrument 1 a The input end is modified, that is, two lines with positive and negative button switches 2 and 3 are connected in parallel on the input end, one line corresponds to the positive ear 4 of the battery, and the other line corresponds to the negative ear 5 of the battery.

[0012] Next, connect the other output end of the detection instrument 1 to one end of the composite switch, and the other end of the composite switch is connected to a needle-shaped conductor connector 7 .

[0013] If it is detected whether there is a short circuit between the positive electrode ear 4 and the aluminum-plastic film 6 welded on the positive electrode sheet, first close the positive electrod...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com