Charging battery pack for electric vehicle and method of production

A production method and technology of battery packs, applied in electric vehicles, battery pack parts, secondary batteries, etc., can solve the problems of low energy density of lead-acid batteries, limited effect, increase the weight and volume of lead-acid batteries, etc., and achieve excellent Large battery discharge performance, short battery life and excellent cycle performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

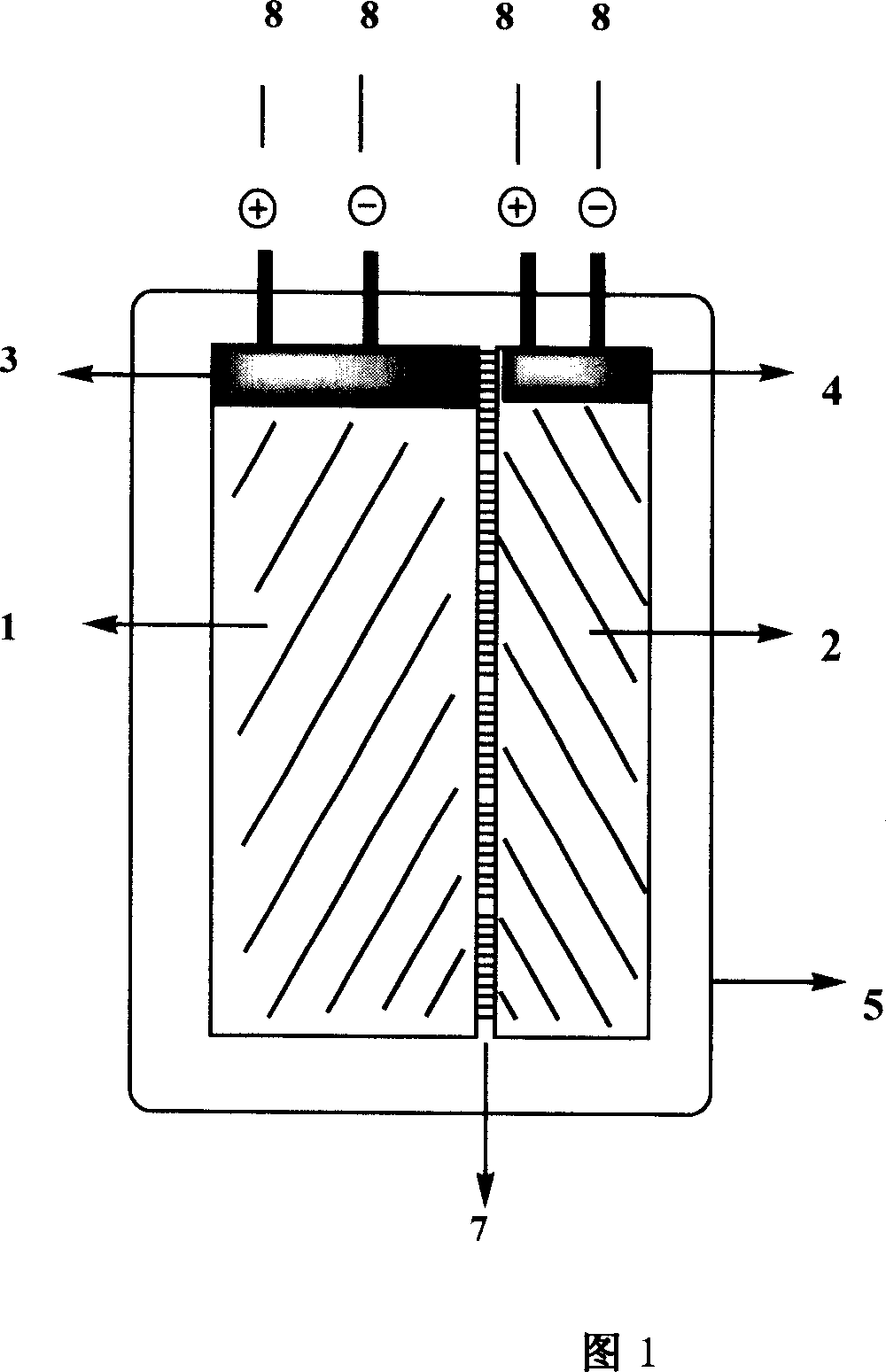

[0035] Using a known production process, a lead-acid battery with a capacity of 10Ah is produced, and then 18 of the lead-acid batteries are connected in series, and a protective circuit board is added to form a lead-acid battery pack with an average output voltage of 36V. Then, a known production process is used to produce a lithium-ion battery with a capacity of 10Ah, and then 10 lithium-ion batteries are connected in series, and a protective circuit board is added to form a lithium-ion battery pack with an average output voltage of 36V. Combining the above-mentioned lead-acid battery pack with the lithium-ion battery pack yields a rechargeable battery pack. The structure of the rechargeable battery pack is shown in Figure 1. Both the lead-acid battery pack and the lithium-ion battery pack are connected to the motor of the electric vehicle.

[0036] The performance of the battery pack is as follows: when the rechargeable battery pack is incorporated into the electric bicycle...

Embodiment 2

[0038] Using a known production process, a lead-acid battery with a capacity of 20Ah is produced, and then 18 of the lead-acid batteries are connected in series, and a protective circuit board is added to form a lead-acid battery pack with an average output voltage of 36V. Then, a known production process is used to produce a lithium-ion battery with a capacity of 20Ah, and then 10 lithium-ion batteries are connected in series, and a protective circuit board is added to form a lithium-ion battery pack with an average output voltage of 36V. Combining the above-mentioned lead-acid battery pack with the lithium-ion battery pack yields a rechargeable battery pack. Both lead-acid and lithium-ion battery packs are connected to the electric vehicle's electric motor.

[0039] The performance of the battery pack is as follows: when the rechargeable battery pack is incorporated into the electric motorcycle, when starting, climbing, and accelerating, it is mainly powered by the lead-acid...

Embodiment 3

[0041] Using a known production process, a lead-acid battery with a capacity of 20Ah is produced, and then 36 of the lead-acid batteries are connected in series, and a protective circuit board is added to form a lead-acid battery pack with an average output voltage of 72V. Then, a known production process is used to produce a lithium-ion battery with a capacity of 20Ah, and then 20 of the lithium-ion batteries are connected in series, and a protective circuit board is added to form a lithium-ion battery pack with an average output voltage of 72V. Combining the above-mentioned lead-acid battery pack with the lithium-ion battery pack yields a rechargeable battery pack. Both lead-acid and lithium-ion battery packs are connected to the electric vehicle's electric motor.

[0042] The performance test of this battery pack is as follows. The rechargeable battery pack is incorporated into the electric tricycle. When starting, climbing, and accelerating, it is mainly powered by the le...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap