Fuel filter system

A filter system and fuel technology, applied in the direction of charging system, filter circuit, filter separation, etc., can solve the problems of water separation performance deterioration, reduction, loss of water separation performance, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

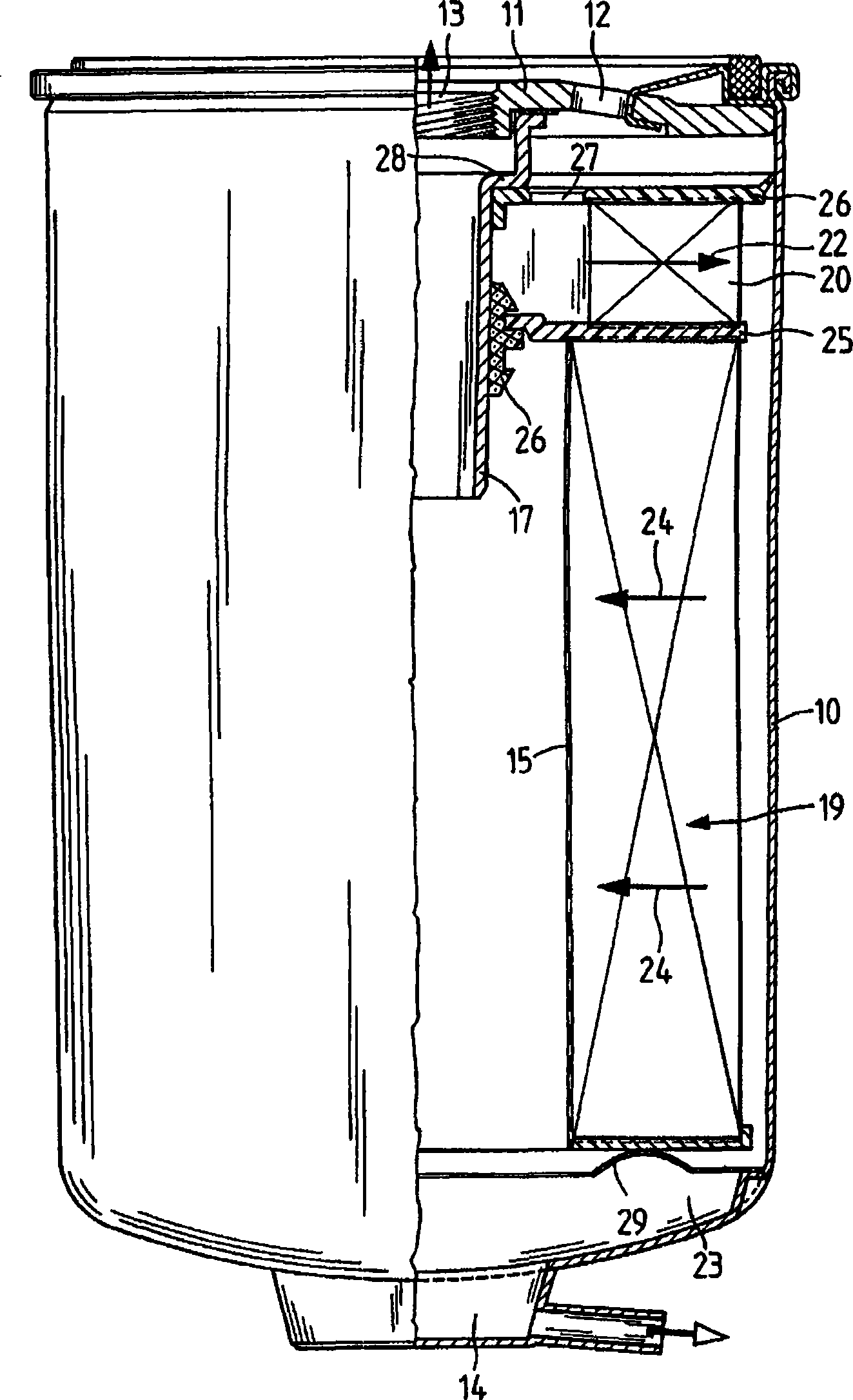

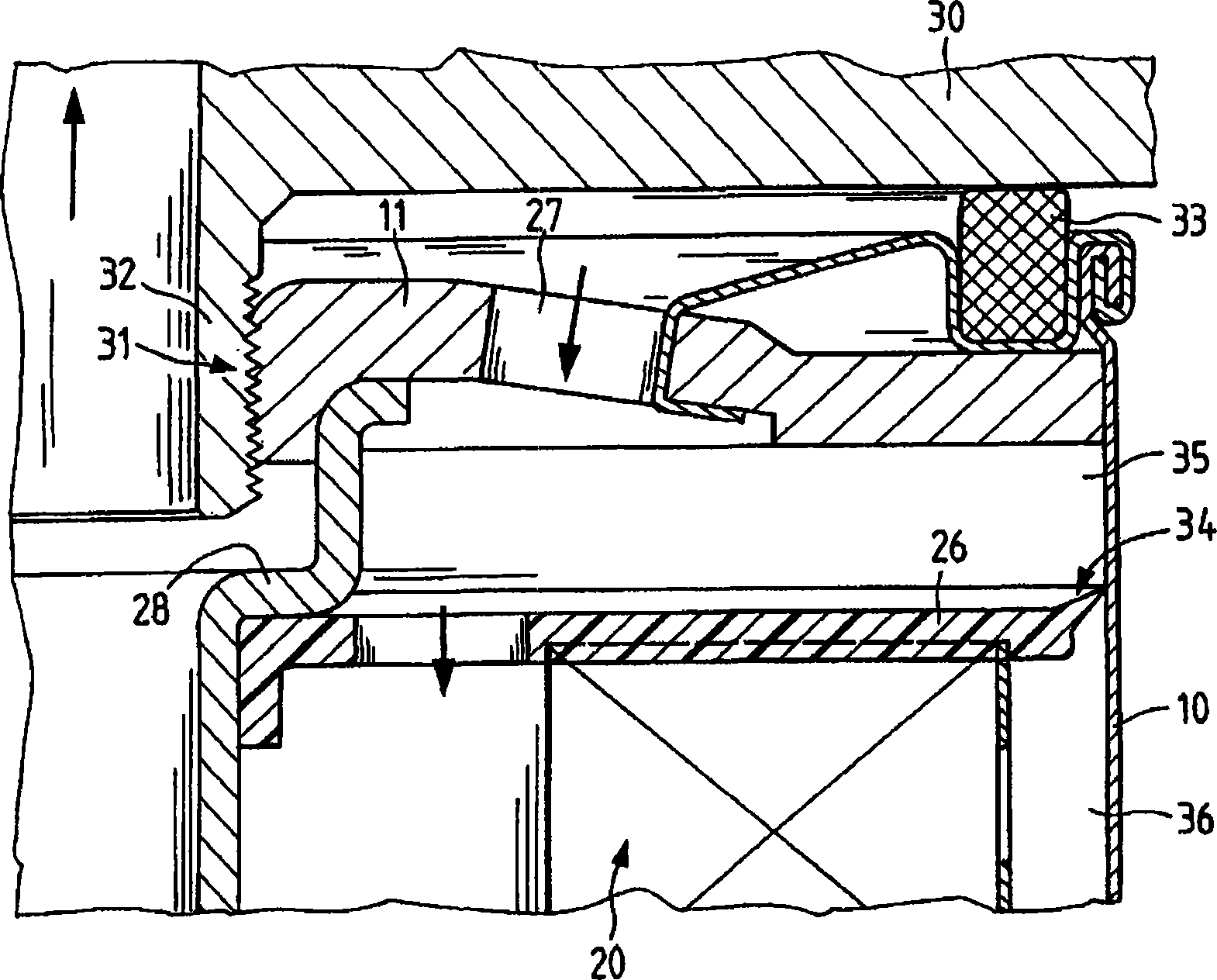

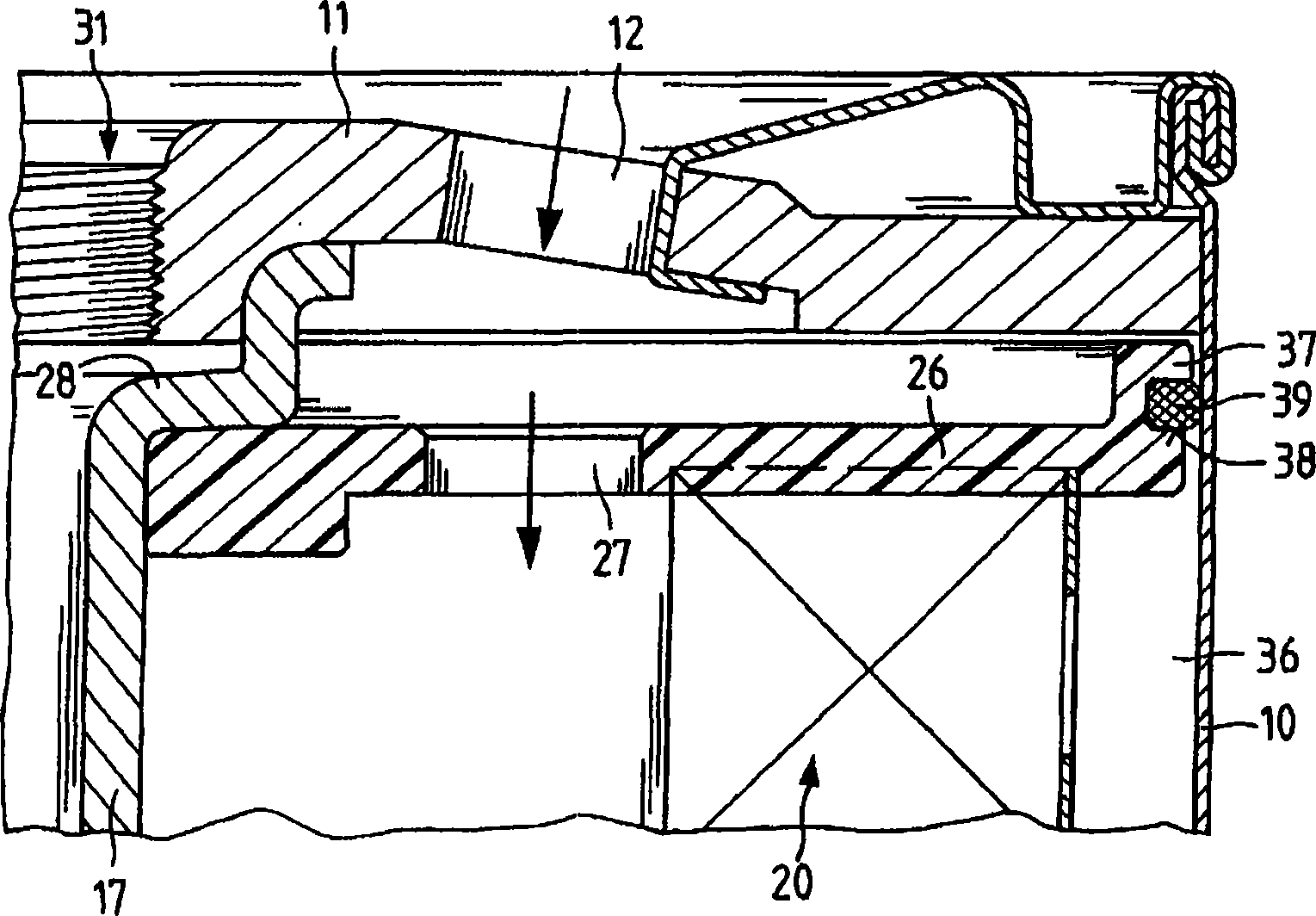

[0016] according to figure 1 The fuel filter includes a housing 10 . The housing 10 is substantially pot-shaped. The housing is closed in the upper region by a cover 11 which has openings 12 for the inflow of fuel, one of which is shown here. The inlets are arranged as perforations on a partial circle and are evenly spaced. Furthermore, an outlet 13 is provided, from which cleaned fuel can be removed. At the lower end of the housing 10 there is a drain valve 14 , which is only schematically shown here. Inside the housing there is a standpipe 17 . In the housing 10 there is a particle filter 19 which is made of a zigzag-folded filter material, which can have a multi-layer structure, for example. A coalescing element 20 is arranged above the particle filter 19 . In the exemplary embodiment shown, this condensation element 20 is likewise produced from a zigzag folded medium. This medium may be a polyester material, polyamide or other material with condensation properties f...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com