Magnetic stabilization fluid bed device capable of being in the high-pressure environment and method of use thereof

A high-pressure environment, application method technology, applied in chemical instruments and methods, chemical/physical processes, solid solvent extraction, etc., can solve the problem of not fully revealing magnetically stable fluidized beds, not suitable for high-pressure operation, and not revealing how to transport powder. And other issues

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

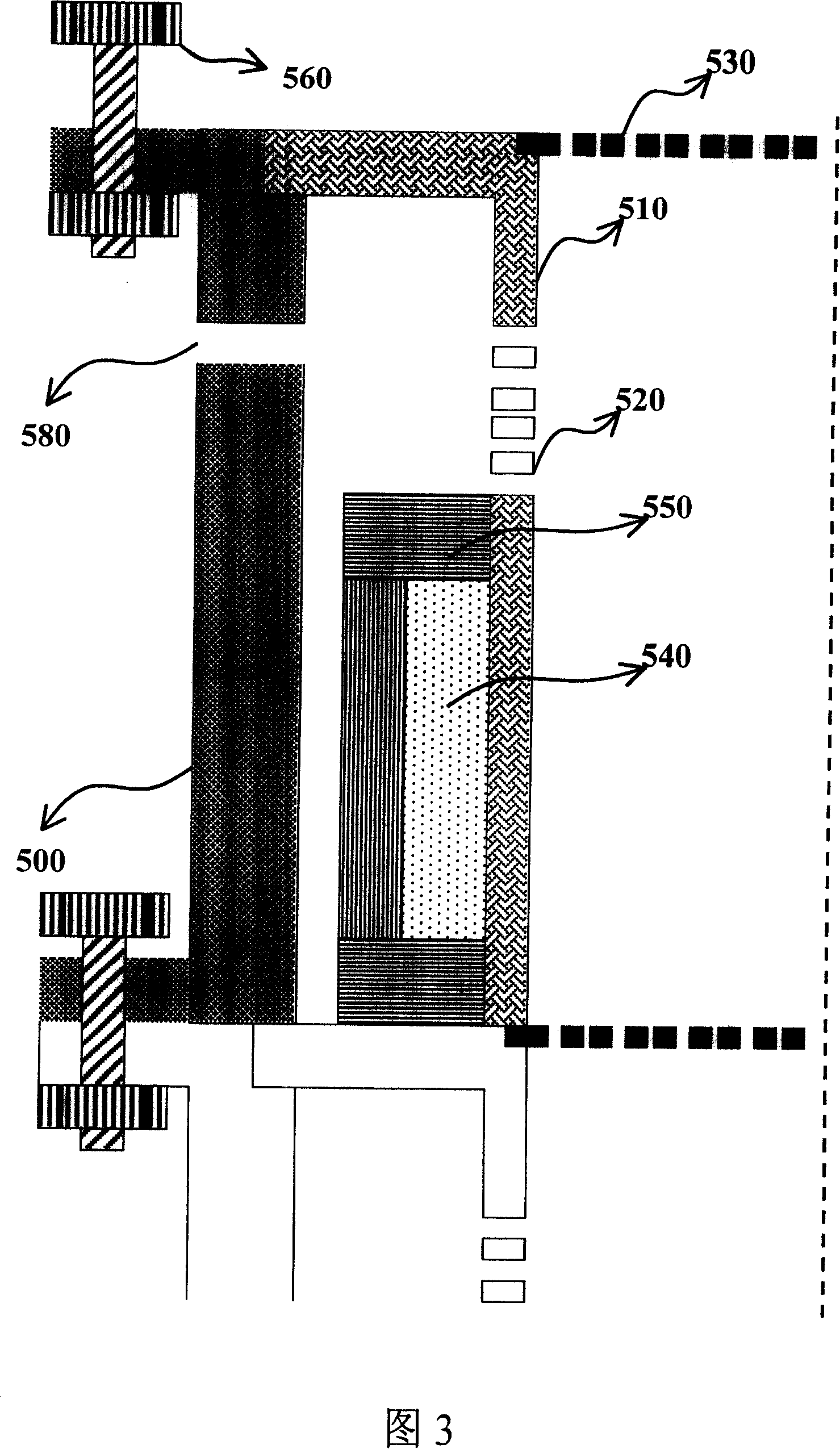

[0063] The content, features, and embodiments of the present invention are described below through the drawings, so that your examiner has a better understanding of the present invention.

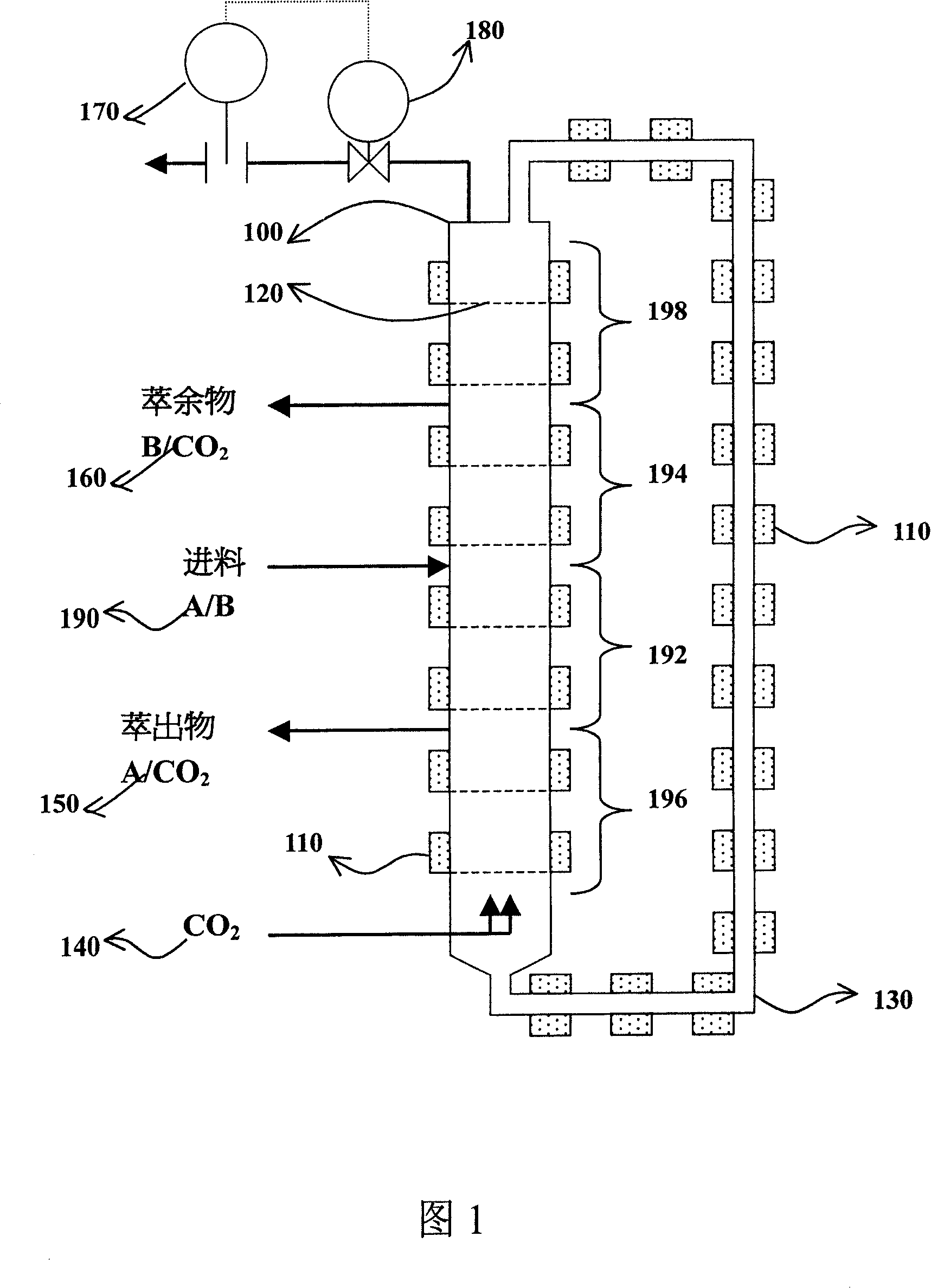

[0064] Please refer to Figure 1 to reveal the process of the present invention:

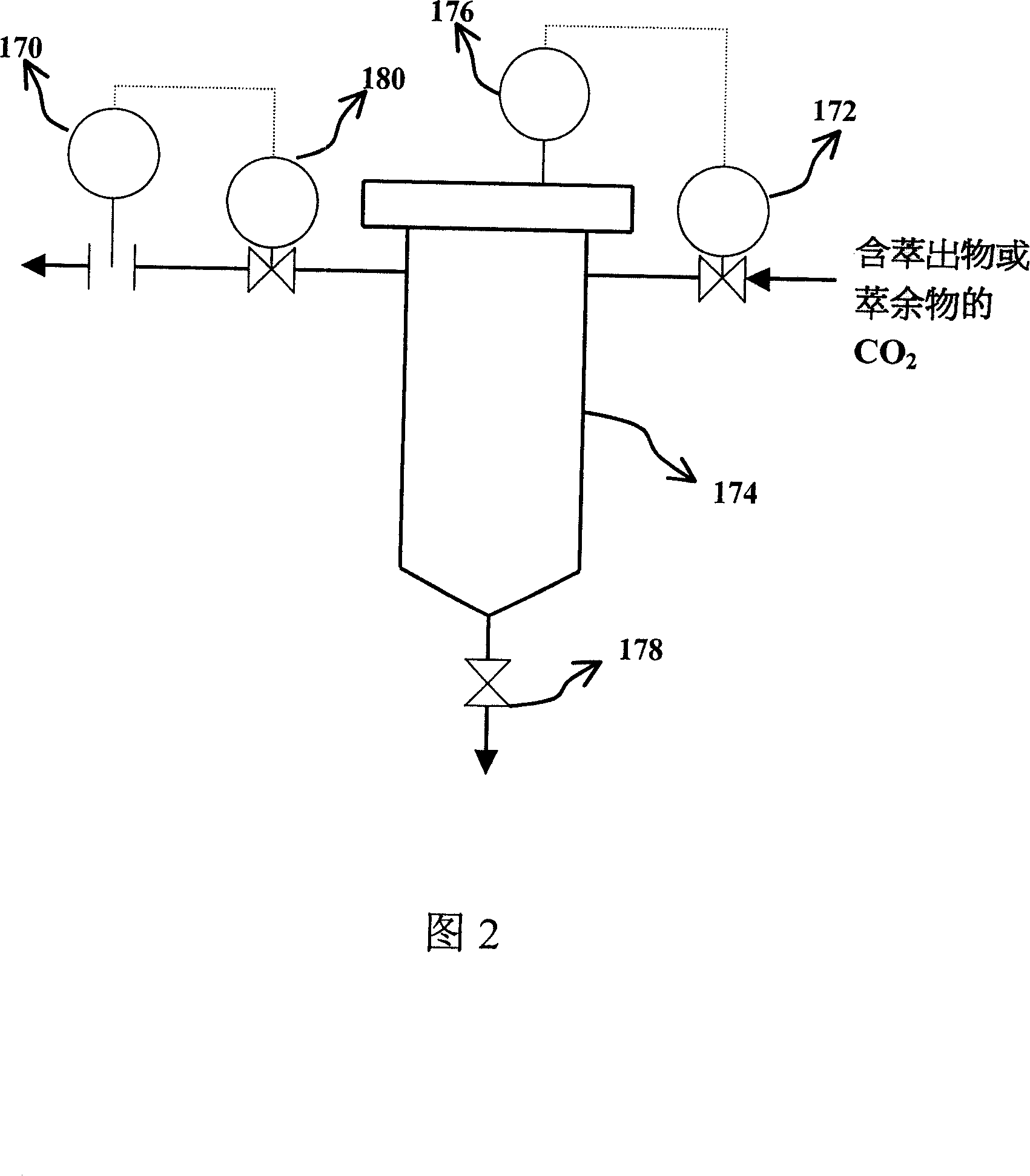

[0065] 1. On a reverse contact column 100, a plurality of electromagnetic coils 110 are arranged, and a mesh sieve plate 120, and the magnetic valve 180 is used as an example to cooperate with the magnetic valve to control the downward flow rate of the powder as shown in FIG. 2. A space with low magnetic flux is maintained above the solenoid 110 of each solenoid valve 180 so that the density of magnetizable powder particles in the space can be reduced as much as possible, and most of the powder is immobilized at the bottom.

[0066] 2. Control the closing and closing of the current of the electromagnetic coil 110, load a certain amount of magnetizable powder above each solenoid valve 180, and put it in the rising ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com