Adjustable multi-bottle automatic rotating and purifying device

An automatic rotation and bottle technology, which is applied in bottle filling, packaging, bottling machines, etc., can solve the problems of large area occupied by the device, high cost, and slow cleaning process speed, and achieve the effect of improving speed and efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

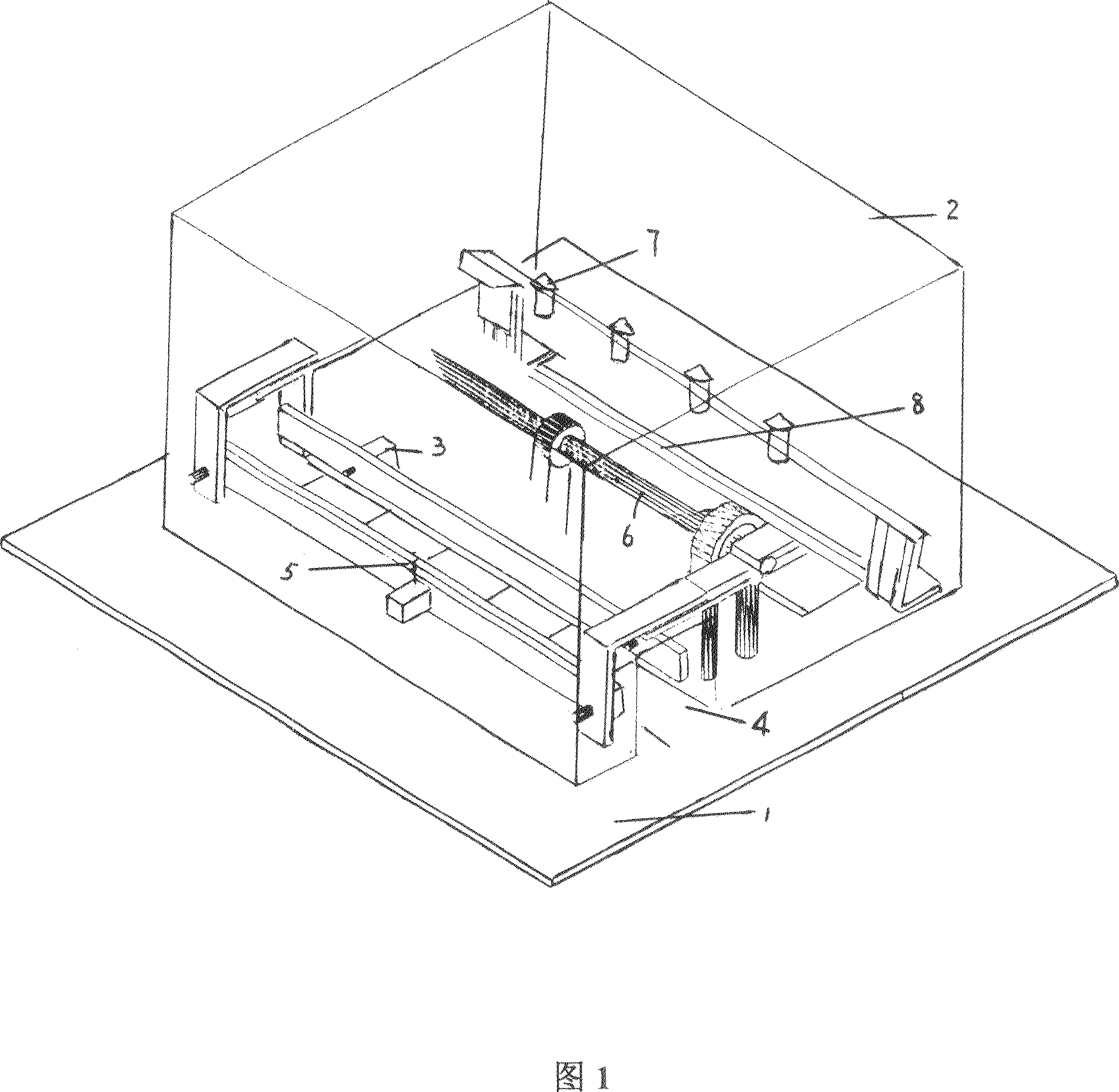

[0024] Please refer to Fig. 1, which is a schematic structural view of a preferred embodiment of the device for automatic rotary purification of multiple bottles that can be adjusted in the present invention. As shown in the figure, the device is mainly composed of a frame 1, a cover 2, two sets of front and rear adjustable and retractable pins 3, a conveyor belt 4, an adjustable bottle clamping mechanism 5, a positioning and rotating mechanism 6, and multiple adjustable spacing. A nozzle 7 and a dust collection device 8 constitute.

[0025] The other mechanisms of the device are all installed on the frame 1, and the cover 2 at the entrance and exit of the conveyor belt 4 has a gap. Subsequent filling process.

[0026] During use, bottle enters this device from conveyer belt 4 after sorting out, and the front positioning pin retracts, and the rear positioning pin protrudes, and the bottle advances on the conveyor belt 4, and is stopped by the protruding rear positioning pin. ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com