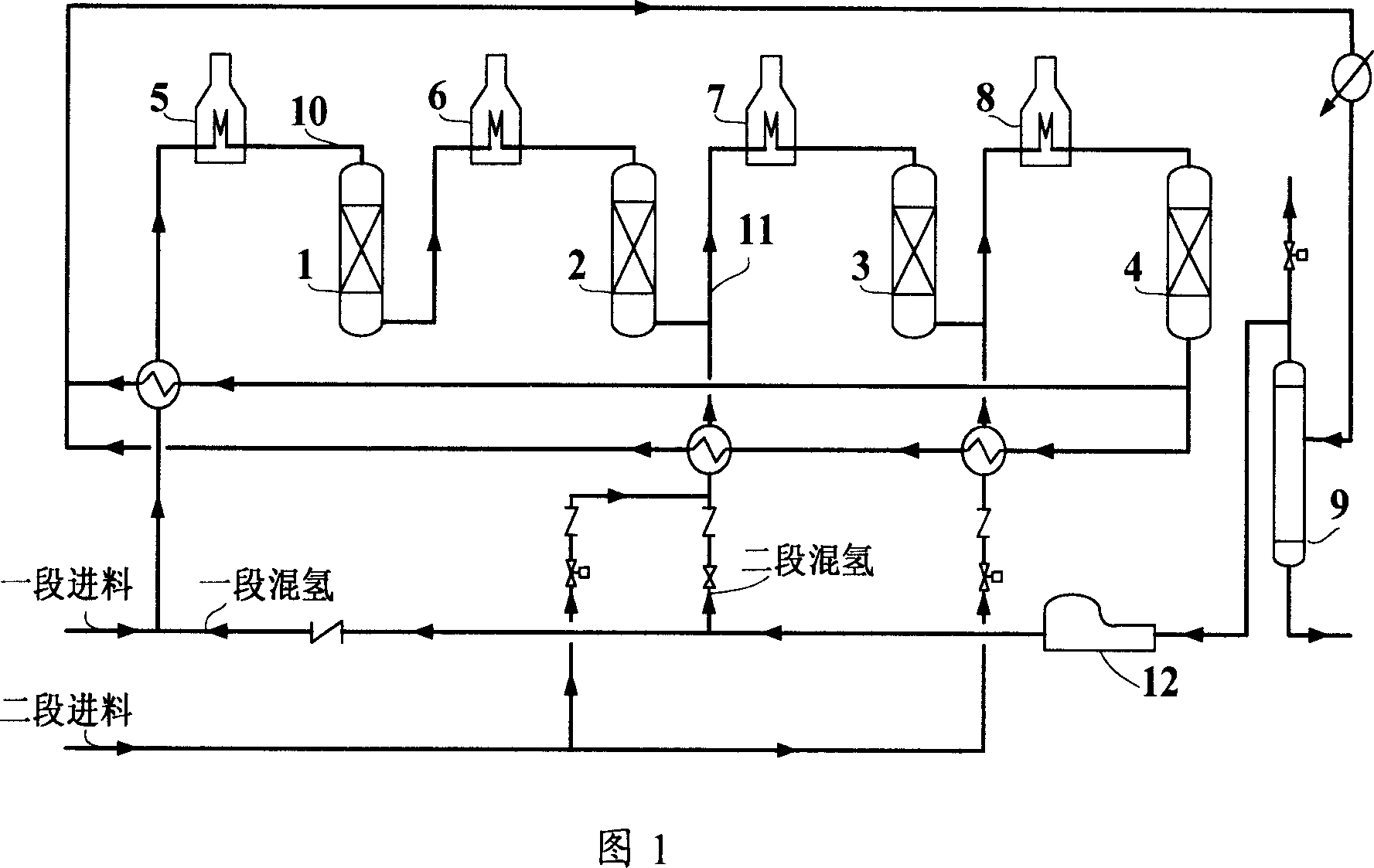

Multistage feeding semi-regenerating catalytic reforming method

A catalytic reforming and semi-regenerative technology, applied in the catalytic reforming of naphtha, etc., can solve the problem of no fresh feed, and achieve the effect of reducing the amount of carbon deposits, prolonging the service life, and evenly distributing the amount of carbon deposits.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

example 1

[0029] The pre-refined reformed raw material is dehydrated through a container equipped with molecular sieves under a pressure of 0.05-0.1 MPa, and its water content is controlled to be ≤3ppm.

[0030] A 100ml reforming test device with two reactors connected in series is used, and the device is equipped with a molecular sieve drying system for removing water in circulating hydrogen. The catalyst loading capacity of the first reactor is 20 ml, and the catalyst loading capacity of the second reactor is 30 ml. A hydrogen circulation is established in the reaction system, and the temperature is raised under the conditions of a pressure of 1.0 MPa and a gas / agent volume ratio of 2000 / 1. When the reactor inlet temperature was 400°C, the raw material A after dehydration was introduced into the first reactor, and the feeding amount was 70ml / hr; then the raw material B was introduced into the second reactor, and the feeding amount was 30ml / hr, and the The feed amount was 30% by volum...

example 2

[0032] The method for adopting example 1 adopts two-stage feed to carry out catalytic reforming, and difference is that raw material A enters the feed rate of the first reactor is 80ml / hr, and raw material B enters the feed rate of the second reactor is 20ml / hr, The feed amount of raw material B is 20% by volume of the total feed amount, and the results are shown in Table 2.

example 3

[0034] The method for example 1 adopts two-stage feed to carry out catalytic reforming, and difference is that what introduces the second reactor is raw material C, and the feeding amount that raw material A enters the first reactor is 95ml / hr, and raw material C enters the second The feed rate of the reactor was 5ml / hr, and the feed rate of raw material C was 5% by volume of the total feed rate. The results are shown in Table 2.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com