Rare earth backflow extraction method and rare earth fully separating process employing the method

An extraction and rare earth technology, applied in the field of solvent extraction and separation of rare earths, can solve problems such as difficult regulation, complex process, incomplete separation, etc., and achieve the effect of reducing the impact of yield, improving the separation effect, and completely separating rare earths

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

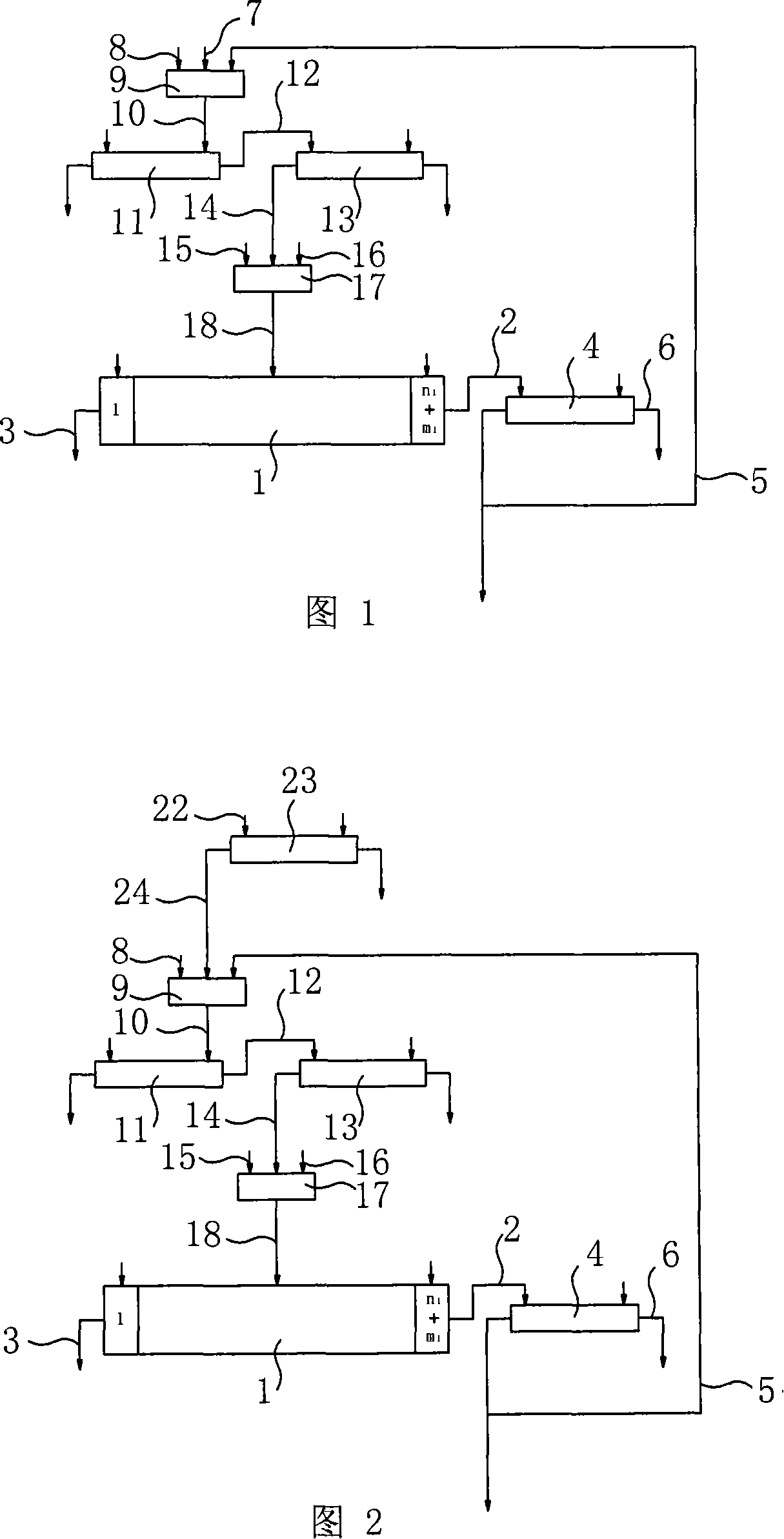

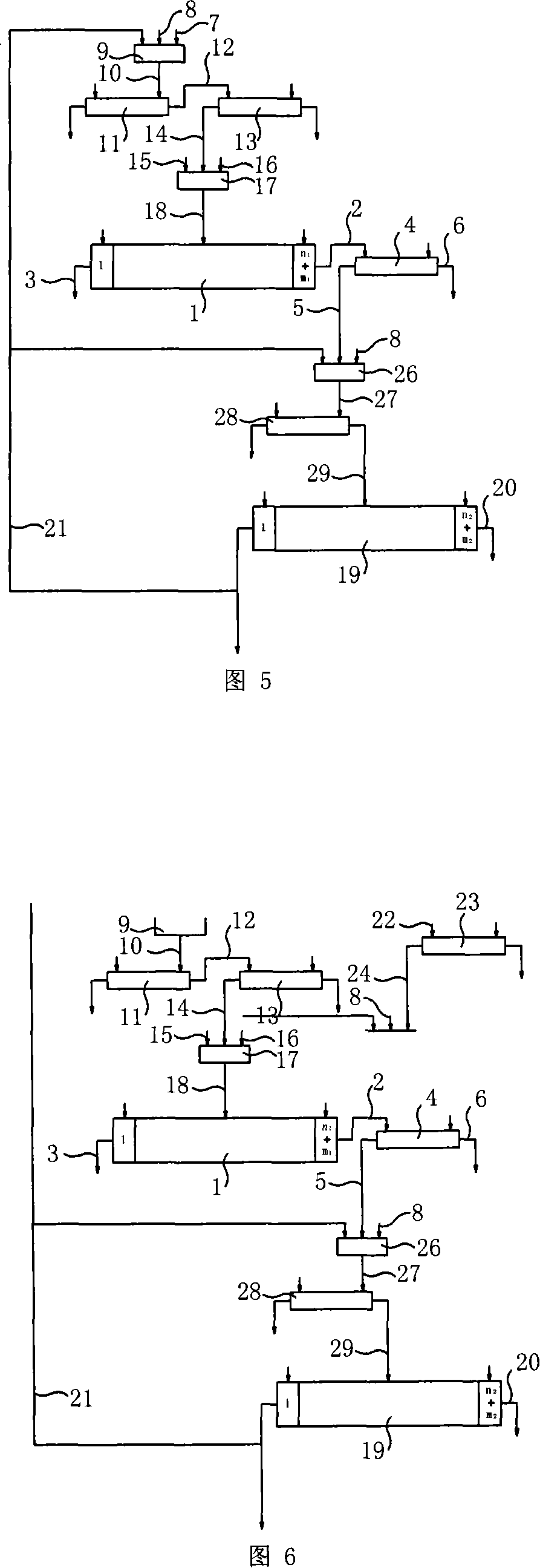

[0030] Referring to Fig. 1, the rare earth raw material is an aqueous solution 7, wherein A 1 It is the only rare earth metal in group A, and it is a reflux metal. The reflux extraction unit only contains one reflux extraction 1, which uses water phase feed, and the outlet water phase 3 of reflux extraction 1. If it only contains B 1 A rare earth metal, then it becomes B 1 The product liquid output, if it contains two or more rare earth metals, it will become the rare earth raw material for the next reflux extraction unit. The outlet organic phase 2 of the reflux extraction 1 is subjected to high-acid stripping in the multi-stage stripping tank 4, and the outlet organic phase 6 of the stripping tank 4 is desaponified and recycled after saponification. Part of the stripping solution is used as A 1 The product liquid output, a part as reflux liquid 5. After the raw material aqueous solution 7, the reflux liquid 5 and the concentrated alkali 8 are mixed into a low-acid solutio...

Embodiment 2

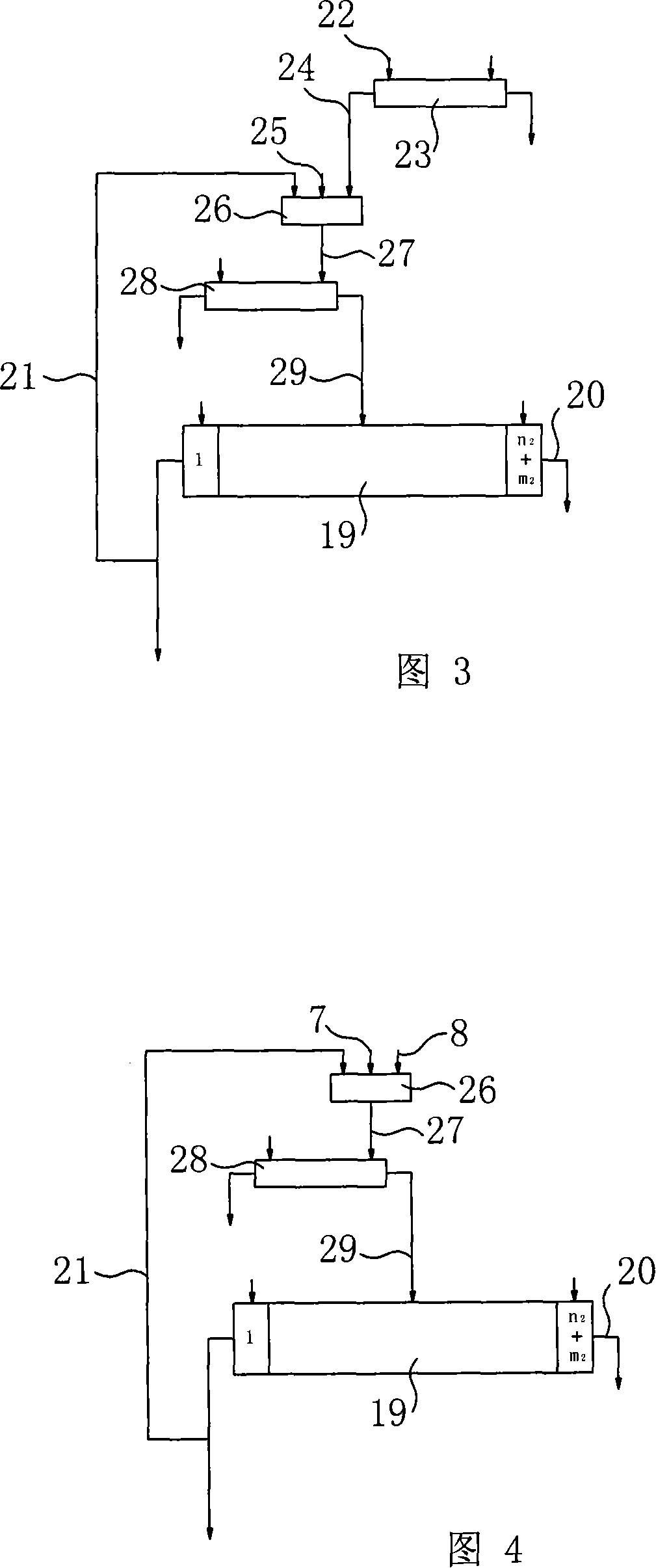

[0032] Referring to shown in Figure 2, the rare earth raw material is an organic phase, where A 1 It is the only rare earth metal in group A, and it is a reflow metal. This embodiment is basically the same as embodiment 1, except that the rare earth raw materials are different, one is the organic phase 22, and the other is the aqueous solution 7. The organic phase 22 is subjected to high-acid countercurrent stripping in the stripping tank 23, and the organic phase at the outlet of the stripping tank 23 is desaponified and recycled after saponification. The outlet water phase 24 of the stripping tank 23 is equivalent to the aqueous solution 7 in the embodiment 1, and others are the same as the embodiment 1.

Embodiment 3

[0034] Referring to Fig. 3, the rare earth raw material is an organic phase 22, wherein B 1 It is the only rare earth metal in group B, and it is a reflux metal. The reflux extraction unit only includes a reflux extraction 19, which uses an organic phase feed, and the outlet organic phase 20 of the reflux extraction 19. If it only contains A 1 , then after it is stripped, the stripped liquid becomes A 1 The product liquid is output. If the organic phase 20 contains two or more rare earth metals, it will become the rare earth raw material for the next reflux extraction unit. Outlet aqueous phase 21 of reflux extraction 19, a part is as B 1 The product liquid output, a part as reflux liquid 21. The raw material liquid organic phase 22 is subjected to high-acid stripping in the multi-stage stripping tank 23, and the organic phase at the outlet of the stripping tank 23 is desaponified and recycled after saponification. After the outlet water phase 24, reflux liquid 21 and conce...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com