Passive optical fiber grating submarine sound signal sensor and making method thereof

An underwater acoustic signal and passive optical fiber technology, which is applied in the direction of using optical devices to transmit sensing components, transducers and instruments used underwater, etc., can solve the problem of low sensitivity of underwater acoustic sensors, difficulty in detecting underwater acoustic signals, and pressure sensitivity. Low-level problems, to achieve the effect of small structure, strong anti-interference ability, and extended application field or scope

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

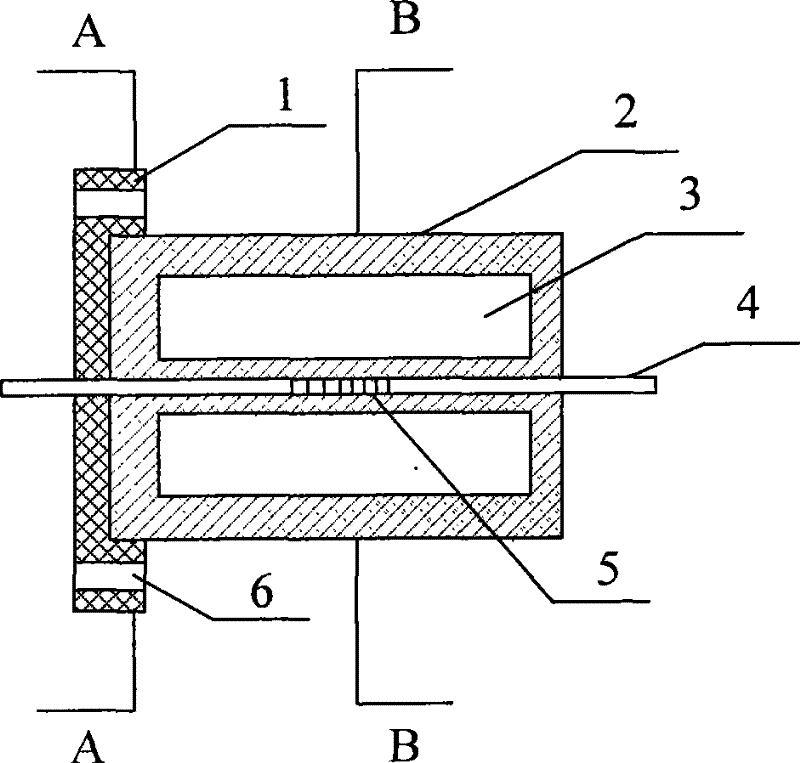

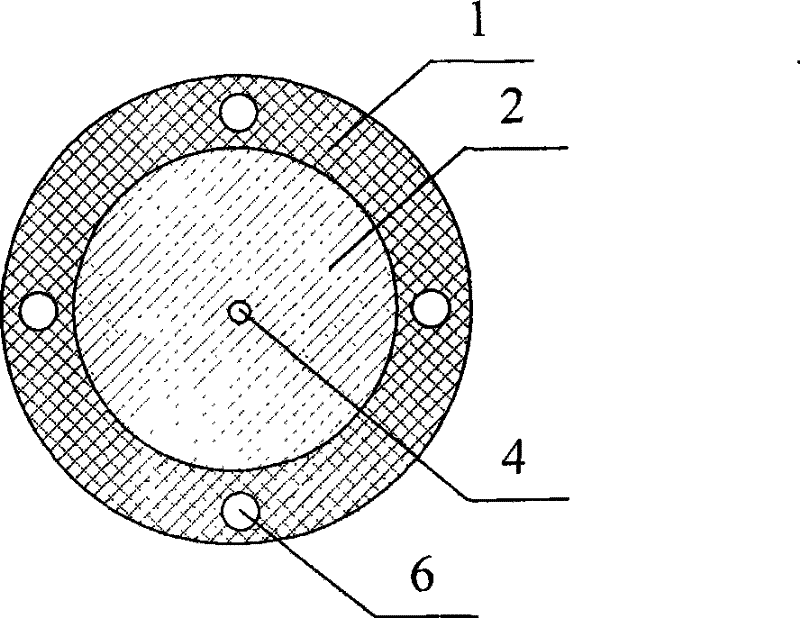

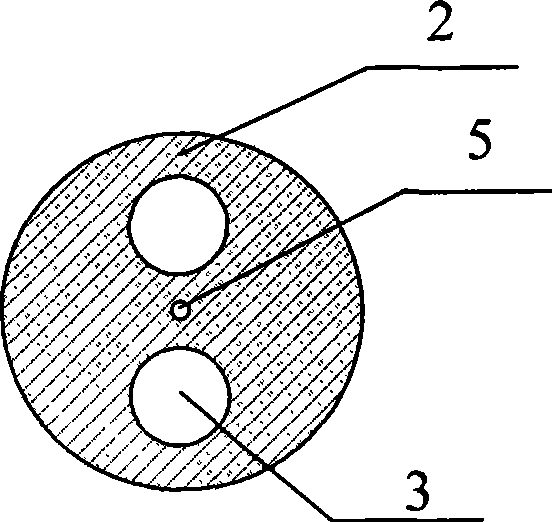

[0023] like figure 1 , figure 2 and image 3 , the simplest structure of the present invention, it is provided with two center-symmetrically distributed cavity bodies 3 inside a polymer package body 2, the two ends of the cavity body 3 are sealed, and a fiber grating 5 passes through and is fixed on The polymer encapsulation 2 is formed on the axis.

[0024] The base 1 is flat or disc-shaped, and the polymer package 2 is embedded in it, and the two are connected by high-strength adhesive.

[0025] There are pigtails at both ends of the fiber grating, and one end of the pigtail passes through the thin through hole in the center of the base, and is used to connect the optical system; the other end is free, or can be used as an array complex of multiple fiber grating hydrophones. Channels are used, and the pigtails 4 of the fiber gratings 5 are sequentially connected in series or in parallel to form an array.

[0026] Further, the pigtail 4 at one end of the fiber grating ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com