Preparation method of fiber grating hydrophone for measuring near-field sound pressure distribution of high-frequency transducer

A technology of high-frequency transducers and optical fiber gratings, applied in the direction of measuring ultrasonic/sonic/infrasonic waves, instruments, measuring devices, etc., can solve the problems of poor precision, low efficiency, and low sound pressure sensitivity, and achieve small size and sound pressure High sensitivity and good spatial resolution

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0021] The present invention will be described in detail below in conjunction with the accompanying drawings and embodiments.

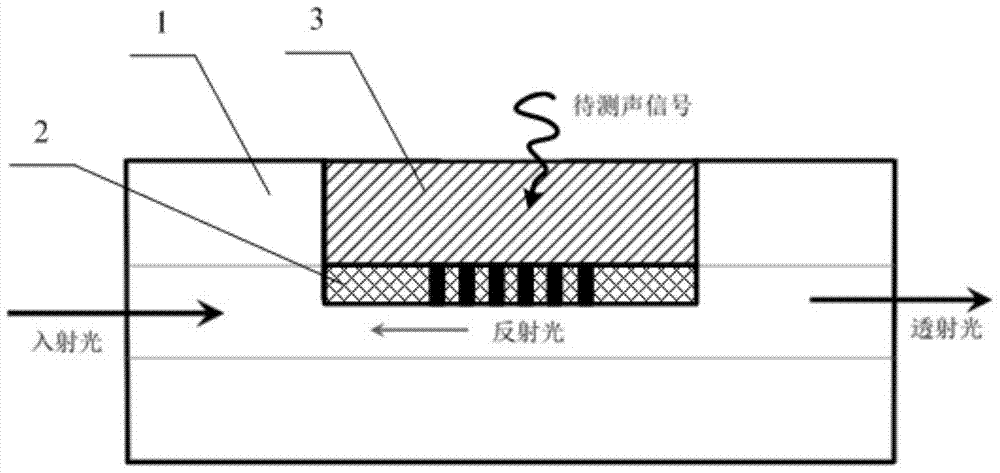

[0022] Such as figure 1 As shown, the fiber Bragg grating hydrophone for measuring the near-field sound pressure distribution of the high-frequency transducer is composed of a D-type standard single-mode fiber 1, a polymer ridge-shaped thin-film optical waveguide Bragg grating 2 and a polymer-coated filling layer 3; D-type standard single-mode fiber 1 is a silicon oxide standard single-mode fiber whose side is polished to form a coating groove; polymer ridge-shaped film optical waveguide Bragg grating 2 covers the bottom surface of the D-type standard single-mode fiber 1 filling groove; polymer coating The filling layer 3 covers the polymer ridge film optical waveguide Bragg grating 2 for encapsulation protection and further acoustic sensitization; the polymer ridge film optical waveguide Bragg grating 2 consists of a polymer ridge film optical wavegu...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com