Method and apparatus for humiture test box shortening high-temperature high moisture-humidity balancing time

A technology that balances time, temperature and humidity. It is used in the calibration of instruments, instrument parts, and analytical materials. It can solve the problems of unstable high temperature and high humidity conditions, inability to meet higher requirements, and long humidity balance time.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 2

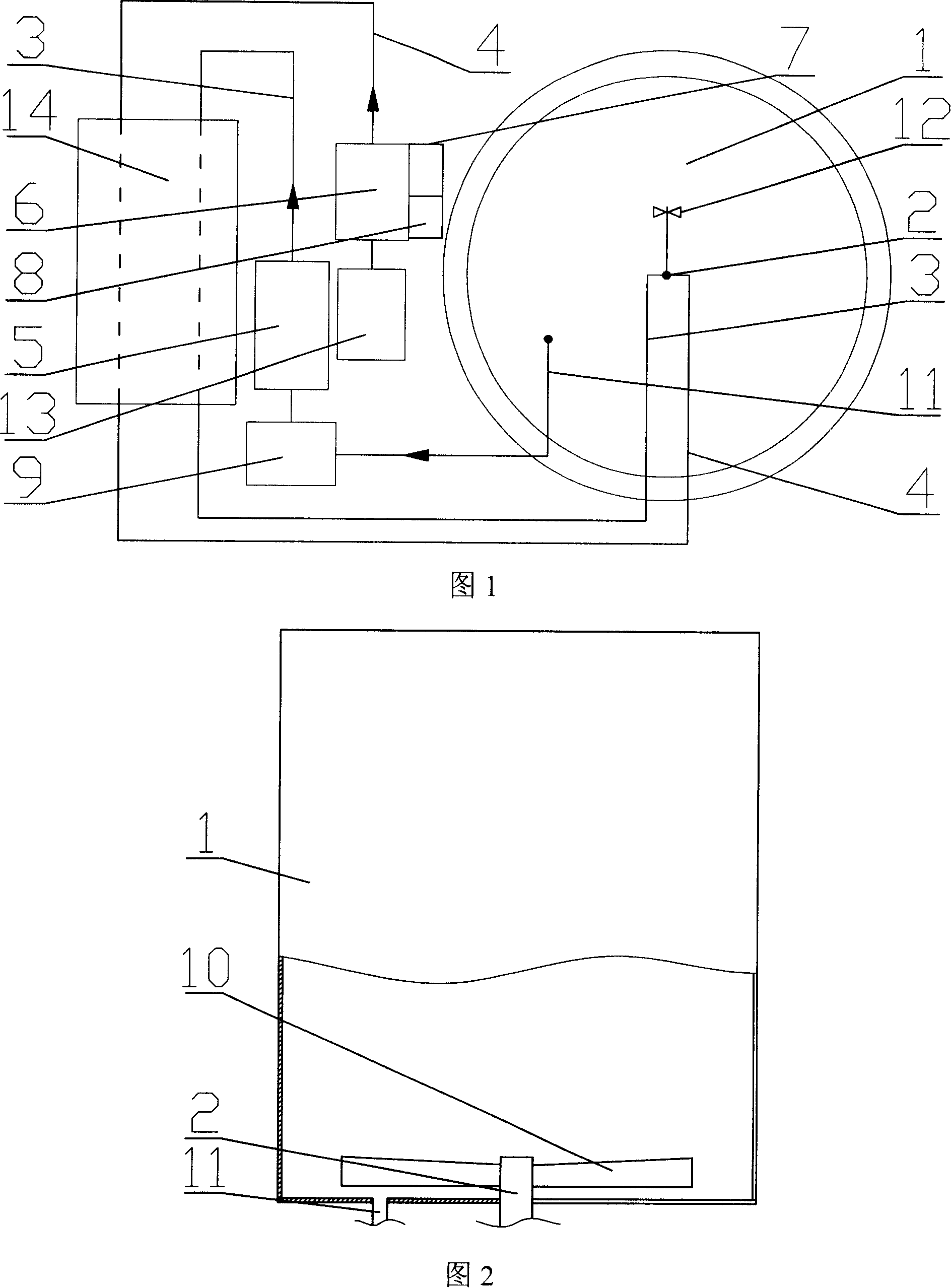

[0017] Embodiment 2 of the present invention: connect the dry gas pipeline (3) and the wet gas pipeline (4) respectively on the interface (2) of the working area (1) of the temperature and humidity test box, and the dry gas pipeline (3) connects the drier ( 5), there is a molecular sieve desiccant in the drier (5), which absorbs the moisture in the gas to obtain dry gas, and the drier (5) is connected to the fan (9); the wet gas pipeline (4) is connected to the saturator (6), and the saturated The device (6) adopts the existing bubbling saturator to obtain saturated moisture input into the working area (1), the inlet of the saturator (6) is connected to the blower fan (13), and the interface (2) is connected with a vent valve ( 12); a heater (7) and a temperature sensor (8) are installed on the saturator (6), and the heater (7) and the temperature sensor (8) control the temperature of the saturator (6) independently.

[0018] When the humidity is to be reduced in the working a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com