Device for taking and putting material carrier of ageing oven

A pick-and-place device and an aging furnace technology, applied in the field of aging furnaces, can solve problems such as unfavorable aging processing automation of electronic materials, increase production labor costs, and the number of electronic materials cannot be further increased, etc., so as to improve the automatic processing capacity and quantity The effect of improving and saving labor costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

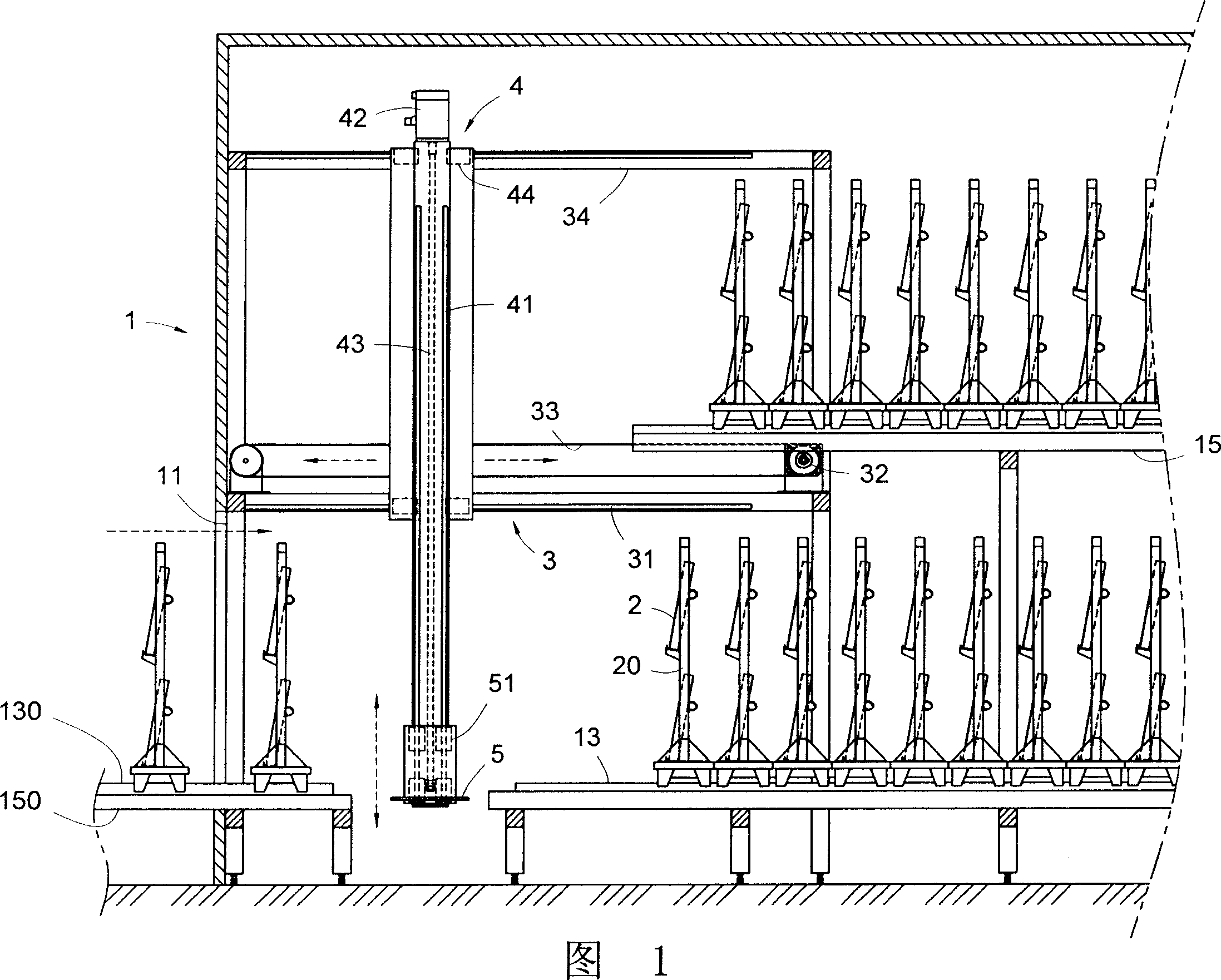

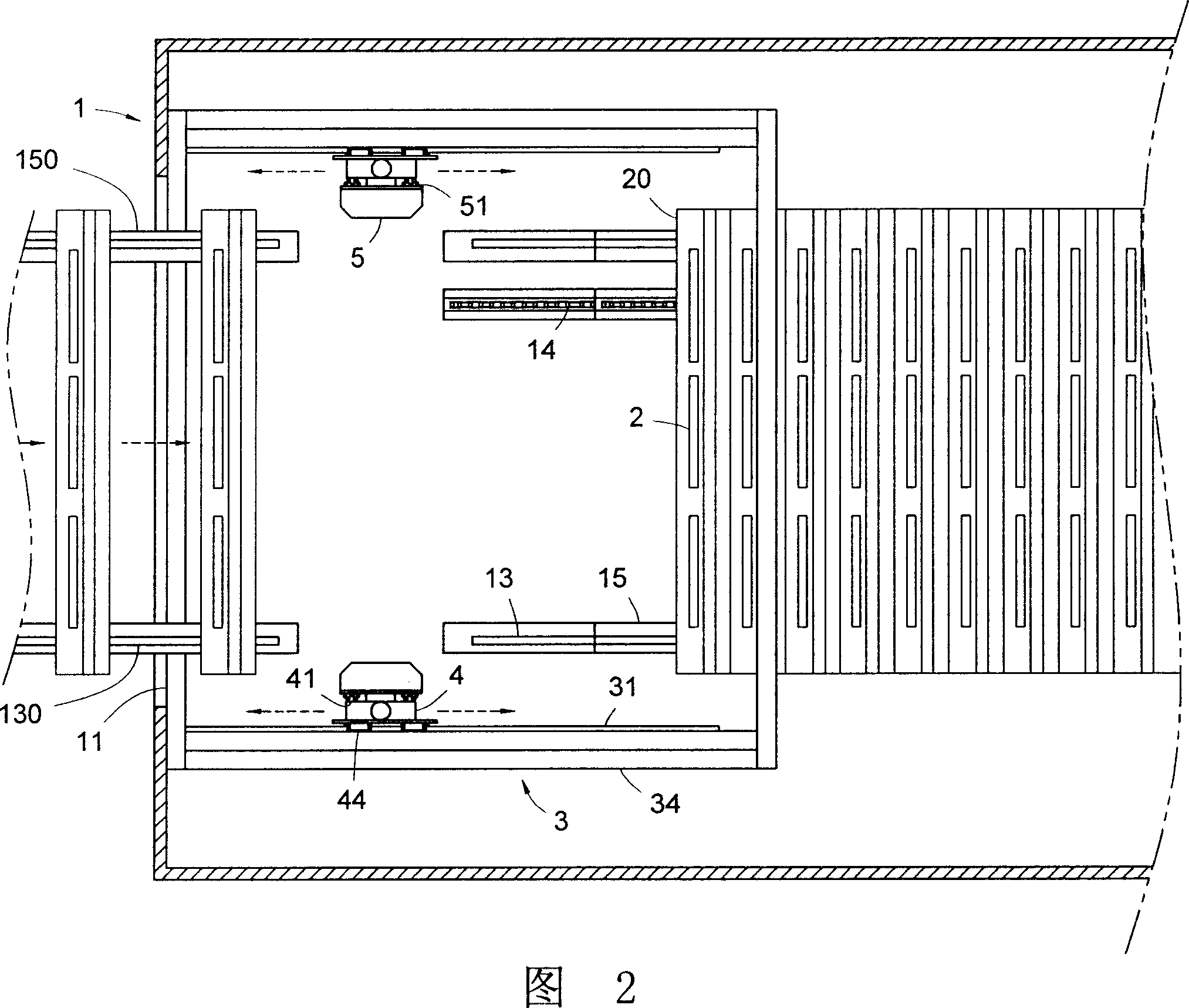

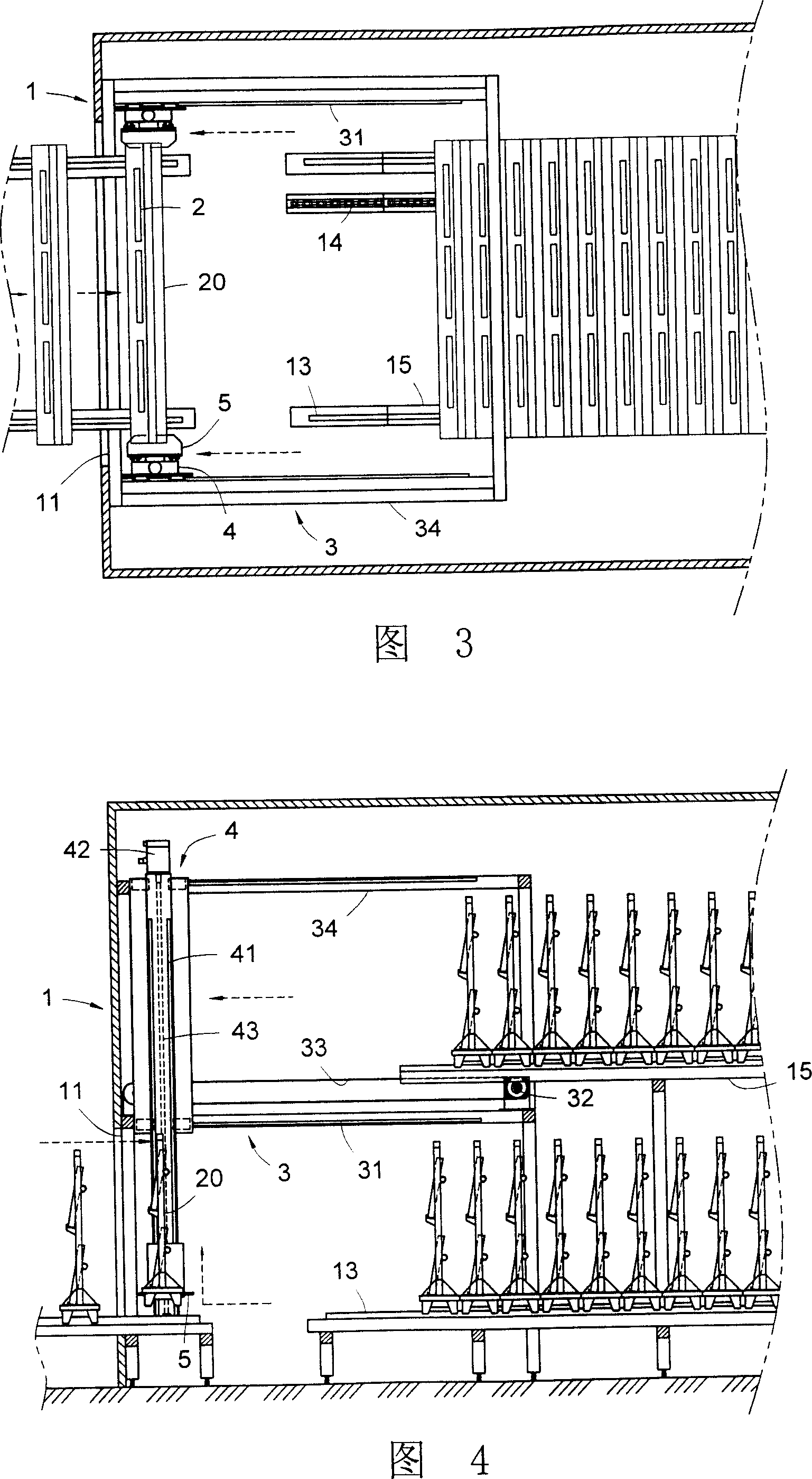

[0021] In order to describe the present invention in detail, a preferred implementation is now described in detail with reference to the accompanying drawings.

[0022] As shown in Fig. 1 and Fig. 2, it is a pick-and-place device for the material carrier of the aging furnace provided by the embodiment of the present invention, which includes:

[0023] An aging furnace 1 is provided with a two-layer support frame 15 inside, each support frame 15 is respectively provided with a track 13, and each layer of track 13 is respectively provided with a transmission chain 14, and on each layer of track 13 is placed a plurality of The carrier 20 is used to accommodate the electronic material 2 , so that the carrier 20 is driven by the transmission chain 14 .

[0024] Two corresponding horizontal transfer units 3 are respectively fixed on two mutually parallel support frames 34 inside the inlet end 11 of the aging furnace 1, and the horizontal transfer unit 3 is respectively provided with...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com