Ink jet printing apparatus having non-contact head maintenance station

A technology of inkjet printing and inkjet print head, applied in printing and other directions, can solve problems such as ink drying

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

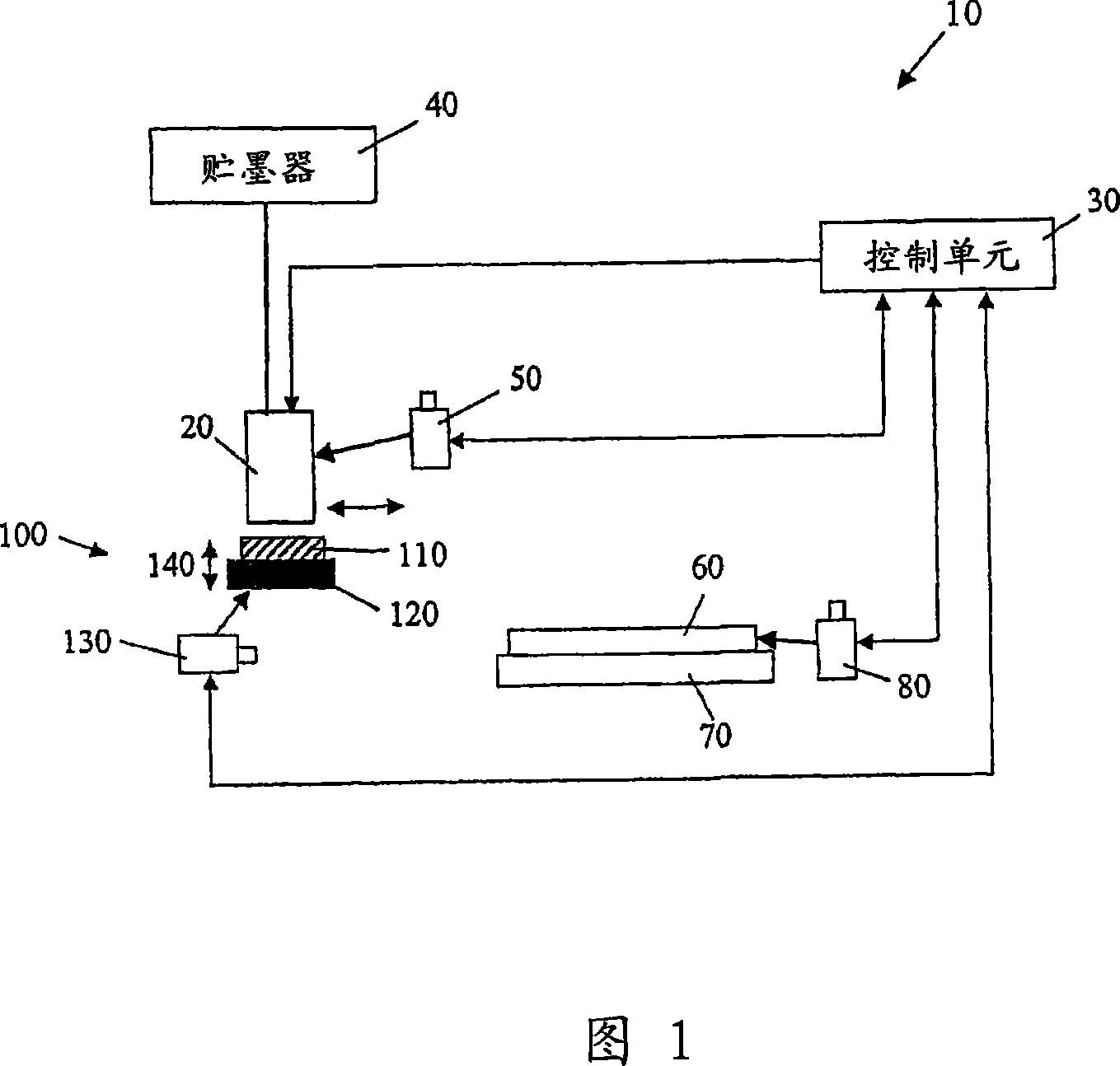

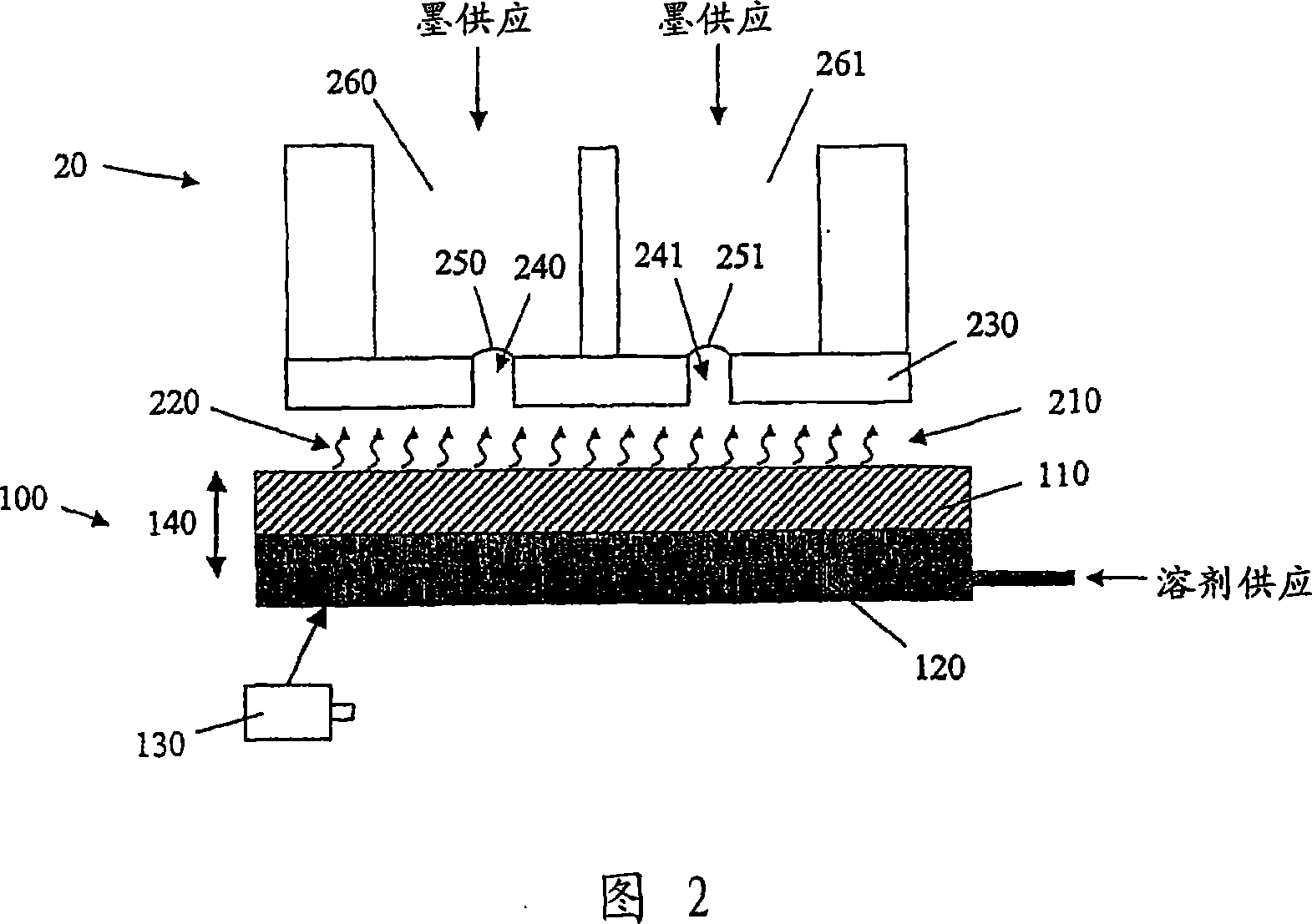

[0015] 1 shows an inkjet printing system 10 that includes an inkjet printhead 20, a controller unit 30 that provides image data and other digital data to the inkjet printhead 20, and a supply of ink to the inkjet printhead 20 through fluid conduits The ink reservoir 40.

[0016] The inkjet printhead 20 may be transported by the head transport mechanism 50 to scan over the ink receiver 60 in a first direction. The ink receiver 60 is provided on the platen 70 . The ink receiver 60 is movable in the second direction under the action of the receiver transfer mechanism 80 . The head transfer mechanism 50 and the receiver transfer mechanism 80 are controlled by the controller 30 .

[0017] Ink jet printheads employing volatile inks such as common solvent and aqueous inks must be handled carefully to prevent the ink from drying out in the ink nozzles. Ink jet printheads are typically capped to prevent ink from drying out in the nozzles when the printhead is idle for extended perio...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com