A woven material comprising tape-like warp an dweft, and an apparatus and method for weaving thereof

A fabric material and warp technology, applied in textiles, papermaking, auxiliary weaving equipment, textiles, etc., can solve problems such as inability to know, and achieve uniform fiber distribution and orientation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

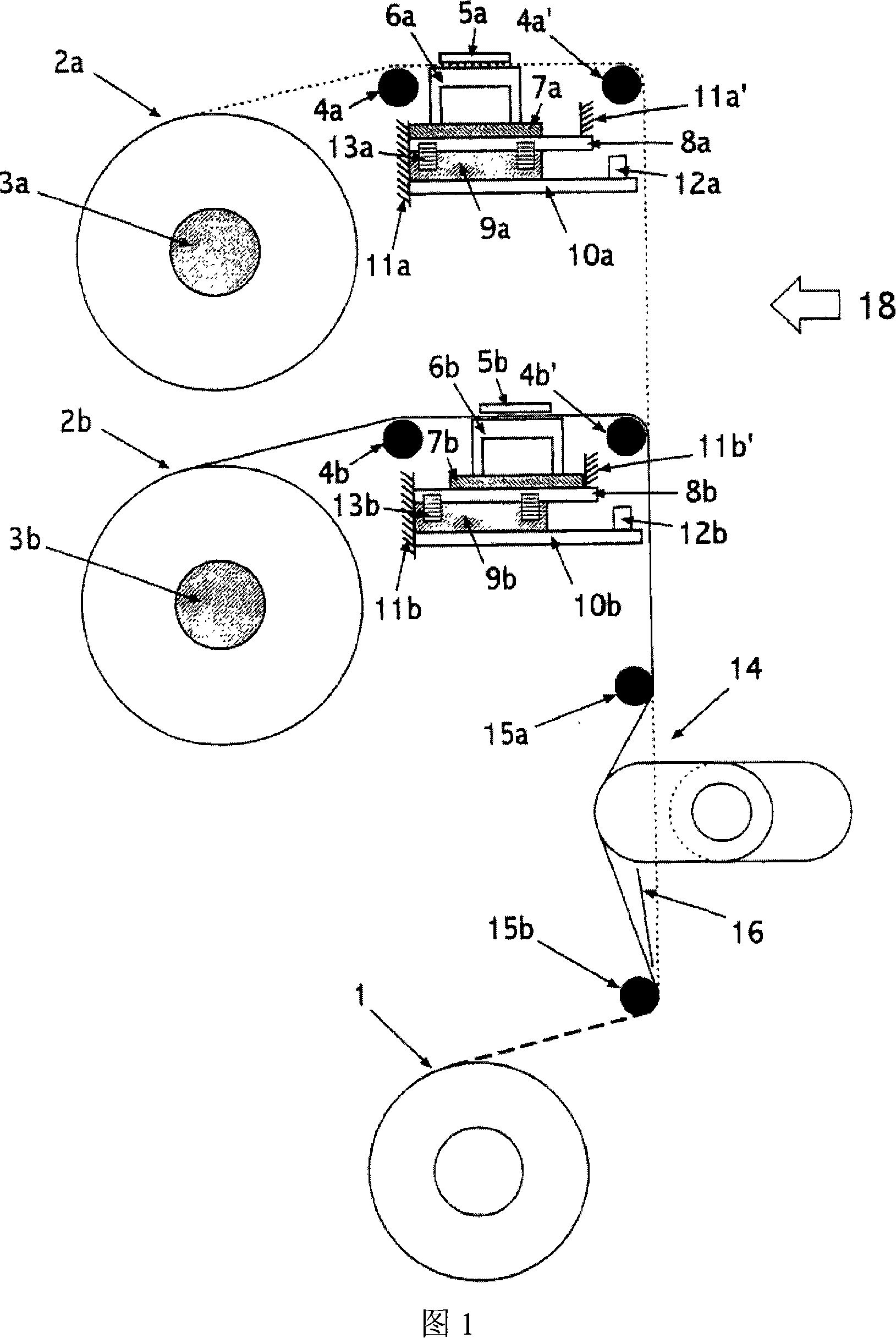

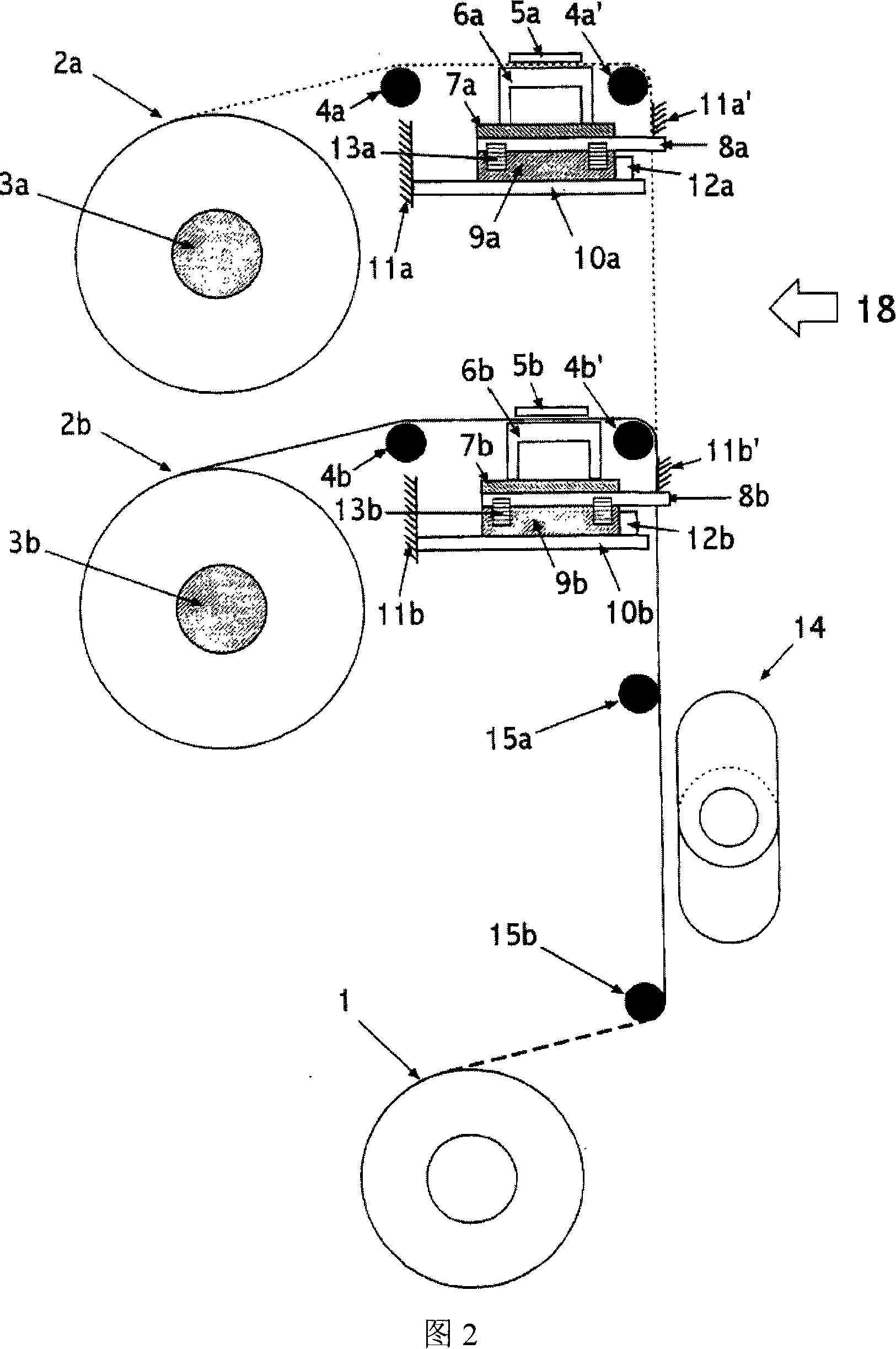

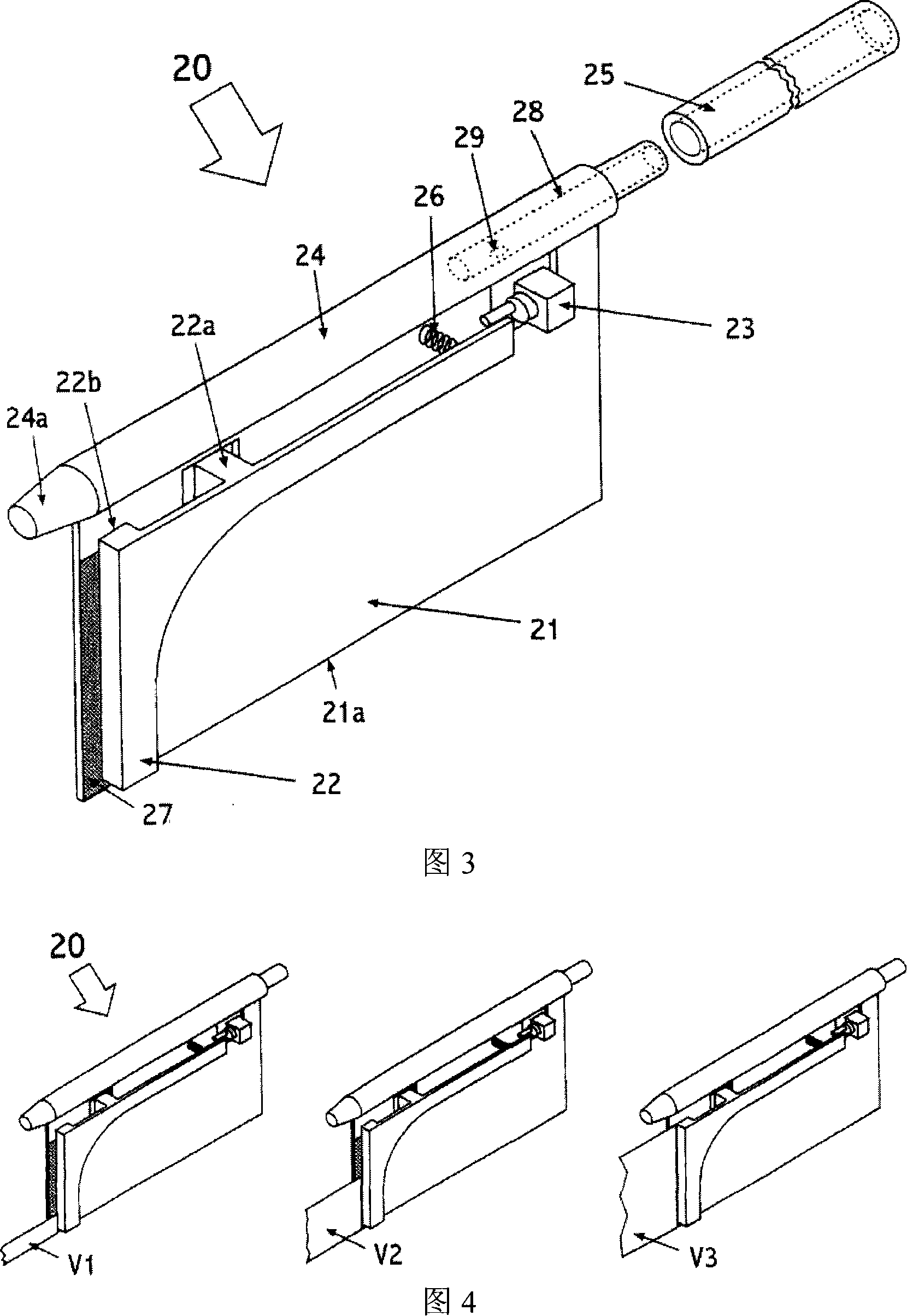

[0071] Various embodiments of the invention are now described separately. Although any other fabric can also be produced, the gist of the invention will only be described by way of example of the production of a flat woven material. In order to describe the present invention within the appropriate scope, the introduction of relevant background aspects with reference to each operating system is described separately.

[0072] (a) Devices for feeding tension-free warp yarns for shedding and fabric take-up

[0073] In traditional weaving, the warp yarns are usually wound together on a warp beam and conveyed horizontally to the weaving equipment through a let-off system. For weaving most materials, one warp beam is used. In terry weaving, two warp beams are used: one for creating the loops and the other for creating the base fabric. Multiple warp beams can also be used, for example, when spinning relatively thin materials, such as conveyor belt cloth. In the manufacture of cert...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com