Method for manufacturing titanium base composite pipe-rod materials

A technology of titanium-based composite materials and manufacturing methods, applied in the direction of manufacturing tools, metal rolling, heat treatment process control, etc., can solve the problems of complex manufacturing process, low production efficiency, high production cost, etc., achieve simple and efficient manufacturing methods, avoid material Effects of waste and avoidance of lamination defects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

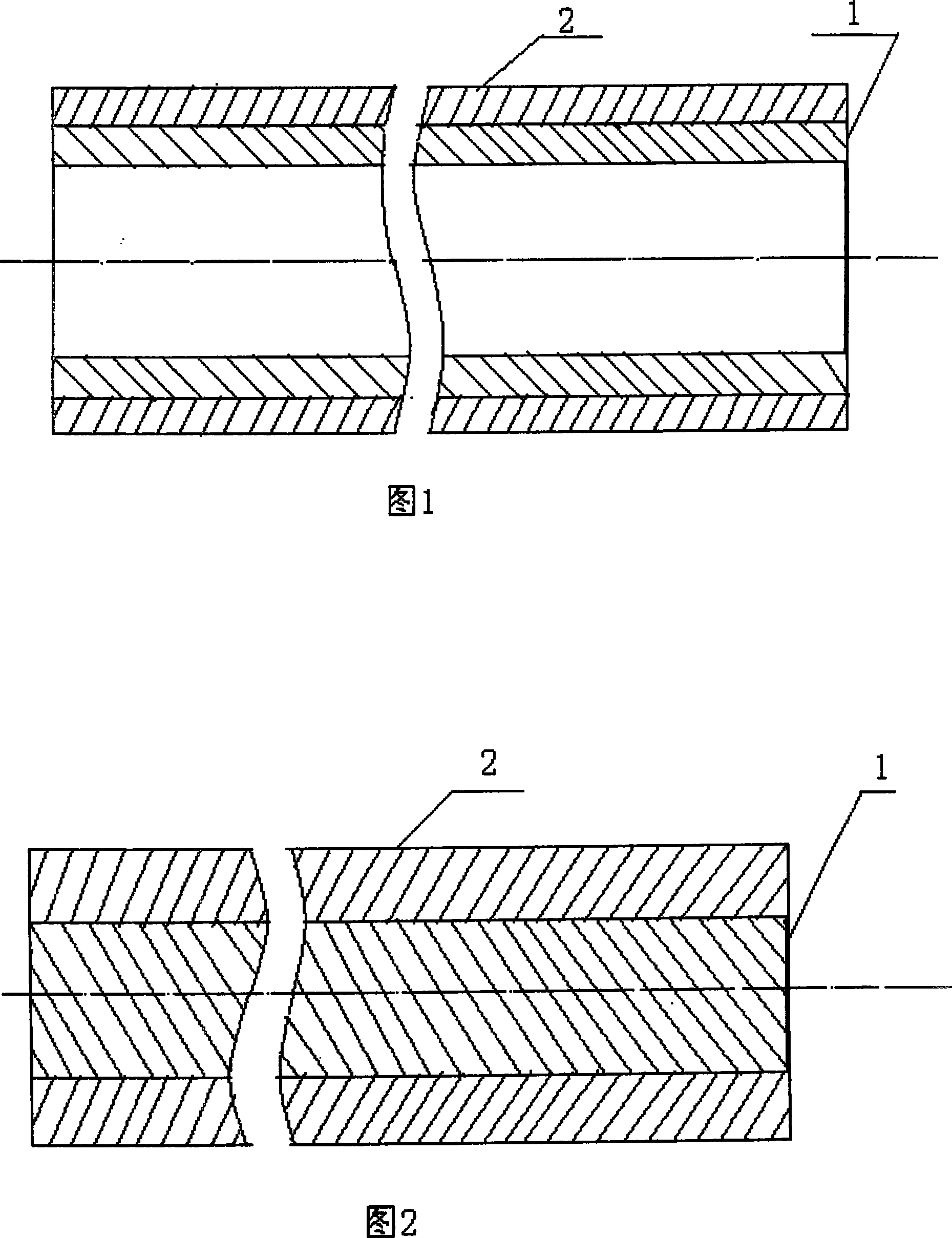

[0012] Below in conjunction with accompanying drawing, specific embodiment of the present invention is described in further detail:

[0013] In Fig. 1, at first, the outer wall of the material core (1) and the inner wall of the titanium tube (2) are cleaned and fully dried by mechanical and chemical methods such as lathe turning inner and outer circles, chemical pickling, etc. The outer wall of the core (1) is covered with a titanium tube (2), and the outer wall of the material core (1) is closely attached to the inner wall of the titanium tube (2) through drawing and extrusion processes, and then rolled into a rectangular cross section by rolling Titanium-based composite pipes of various shapes such as polygons and polygons.

[0014] In order to obtain a good rolling effect, the resistance furnace can be used to protect the heating with inert gas and hold it for a certain period of time before rolling. The heating temperature during this period is 750°C-900°C, and the holding...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com