Method for regenerating cartridge

An ink cartridge and ink-holding technology is applied to chemical instruments and methods, cleaning methods and utensils, and cleaning methods using liquids, etc. It can solve problems such as damaged cables, scrapped ink cartridges, and inability to recycle, and achieve cost savings. The effect of simple method

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

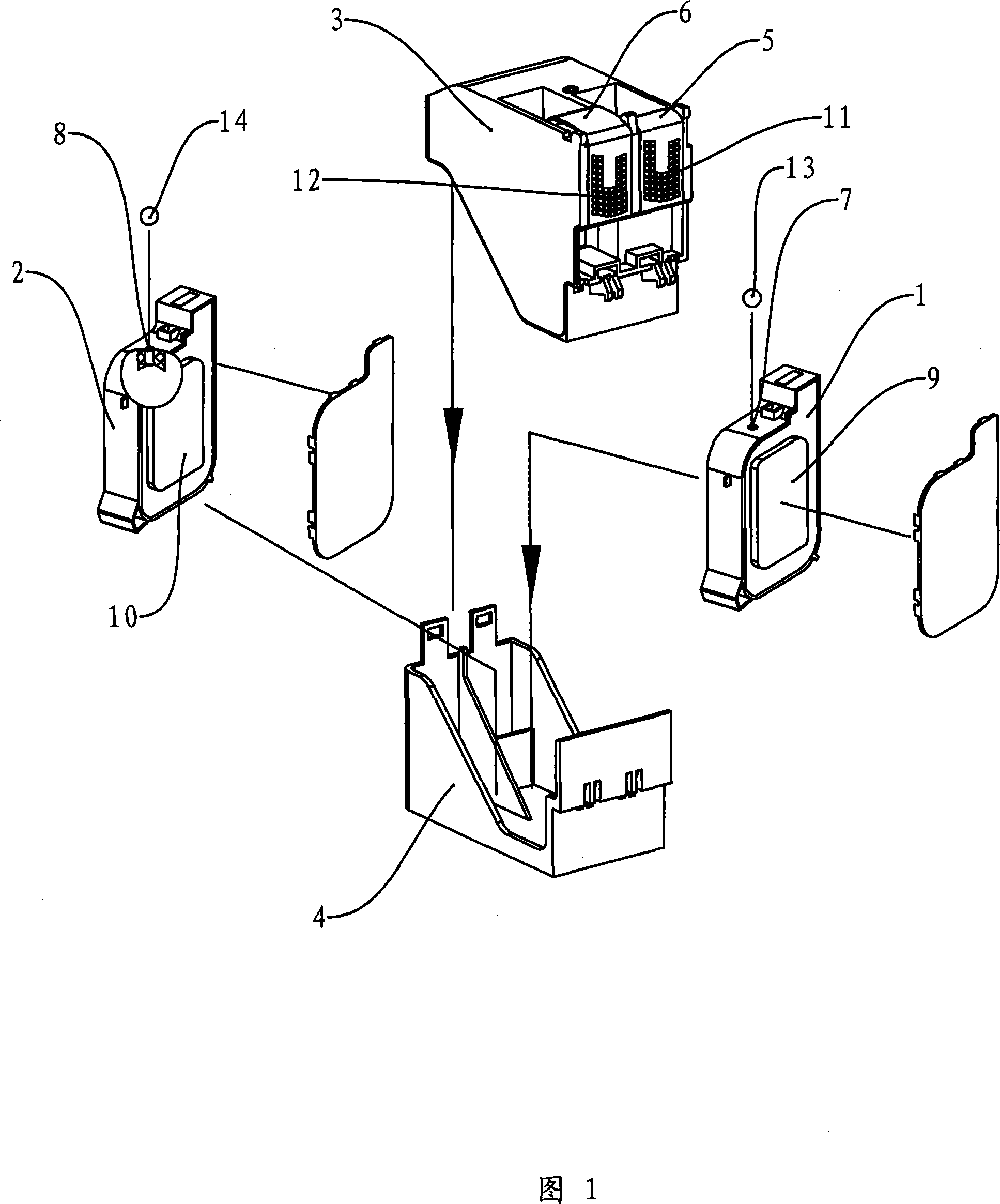

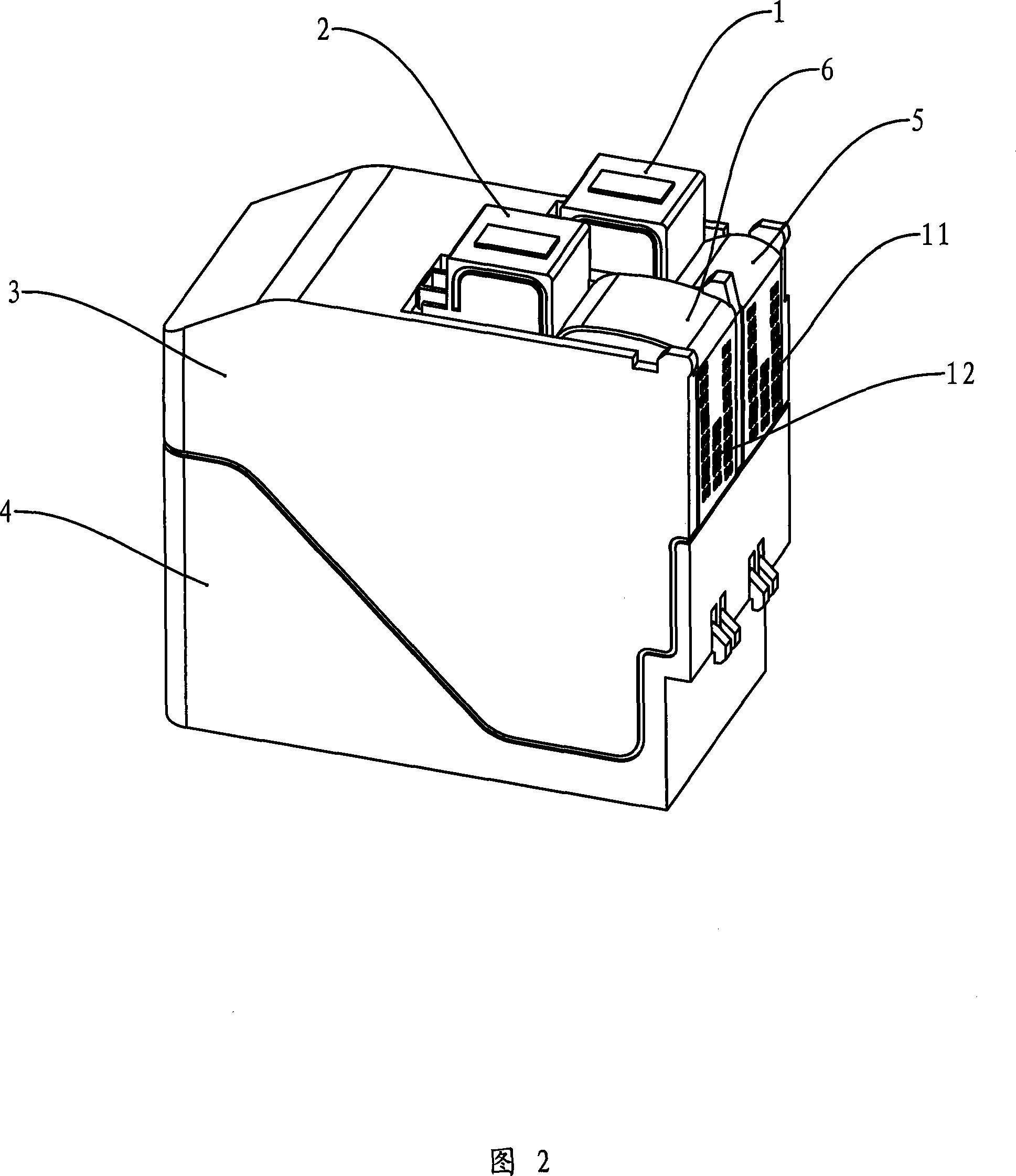

[0025] A method for regenerating an ink cartridge includes the following steps:

[0026] (1) Chip rewriting, using a dedicated rewriter to rewrite the ink cartridge chip to achieve the same or similar original circuit information of the ink cartridge chip.

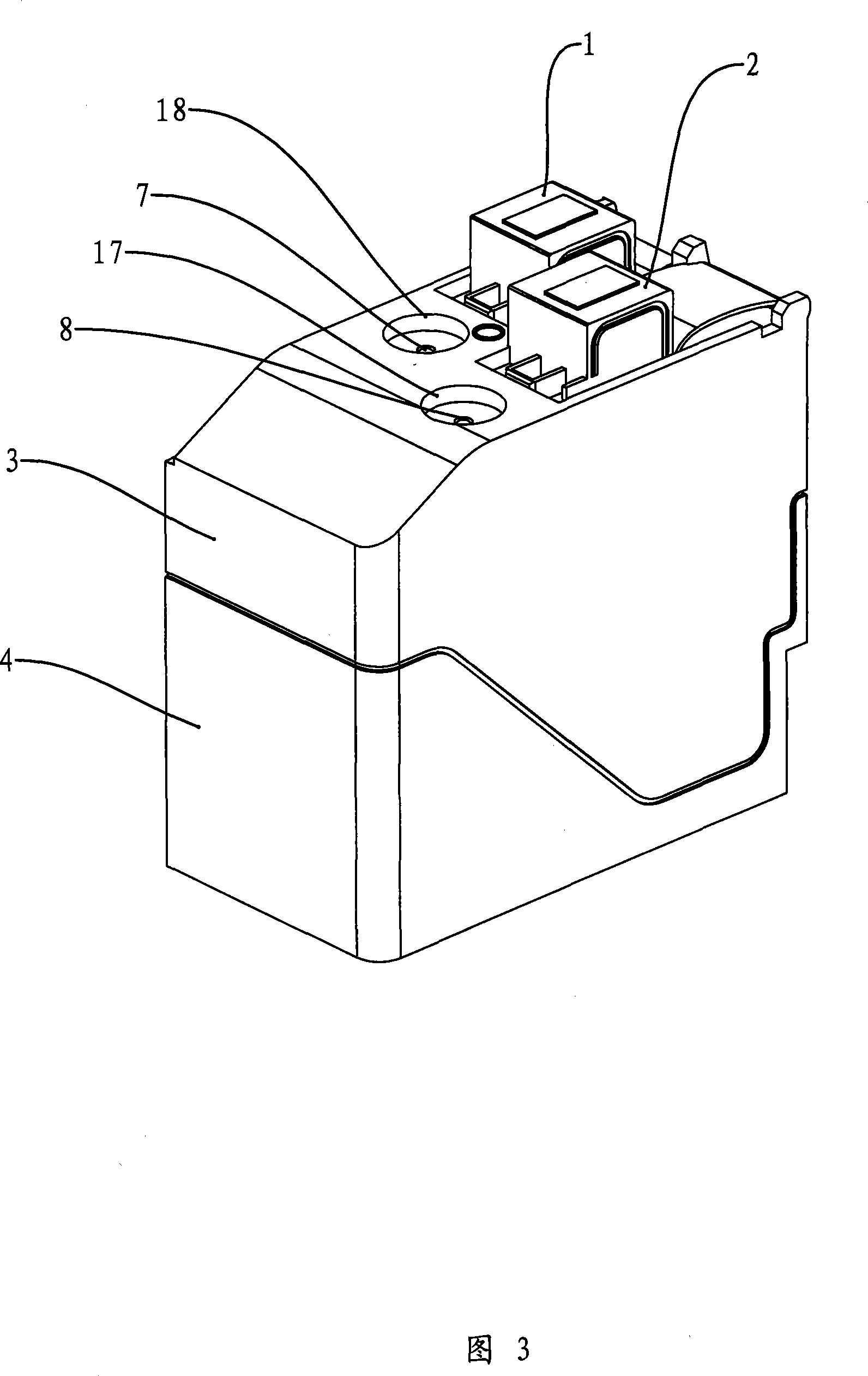

[0027] (2) Drill holes, drill holes 17 and 18 on the outer box of the ink cartridge corresponding to the original ink injection ports 7 and 8 (as shown in Figure 3);

[0028] (3) Remove the steel balls 13, 14 of the original ink filling ports 7, 8 of the gamble, that is, push the steel balls 13, 14 into the ink container or take out the steel balls 13, 14;

[0029] (4) A negative pressure method is used to suck out the remaining ink in the ink cartridge, and the remaining ink in the ink cartridge is sucked out.

[0030] (5) Soak in the cleaning liquid at a temperature of 45℃-55℃, pour the cleaning liquid into the original ink injection ports 9, 10, plug the steel ball holes 17, 18 with a rubber plug, and soak the ink container...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com