Overhead type bus fuel battery motor ventilating dustproof and rainproof design

A technology of fuel cells and engines, which is applied to electric vehicles, the arrangement of cooling combination of power plants, power plants, etc., and can solve problems such as structures, shapes, and sizes that are quite different, can not achieve waterproof effects, and are difficult to design

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

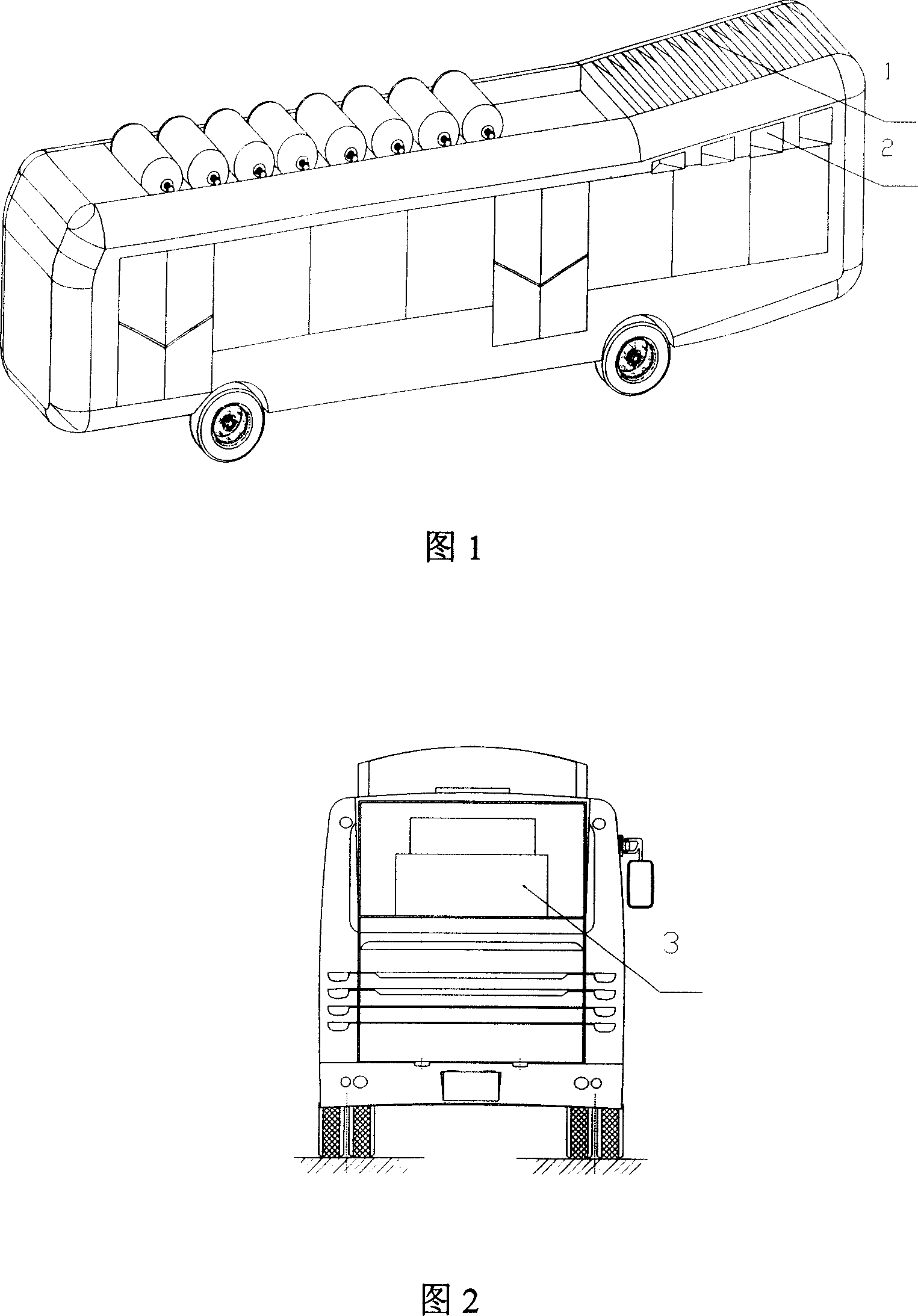

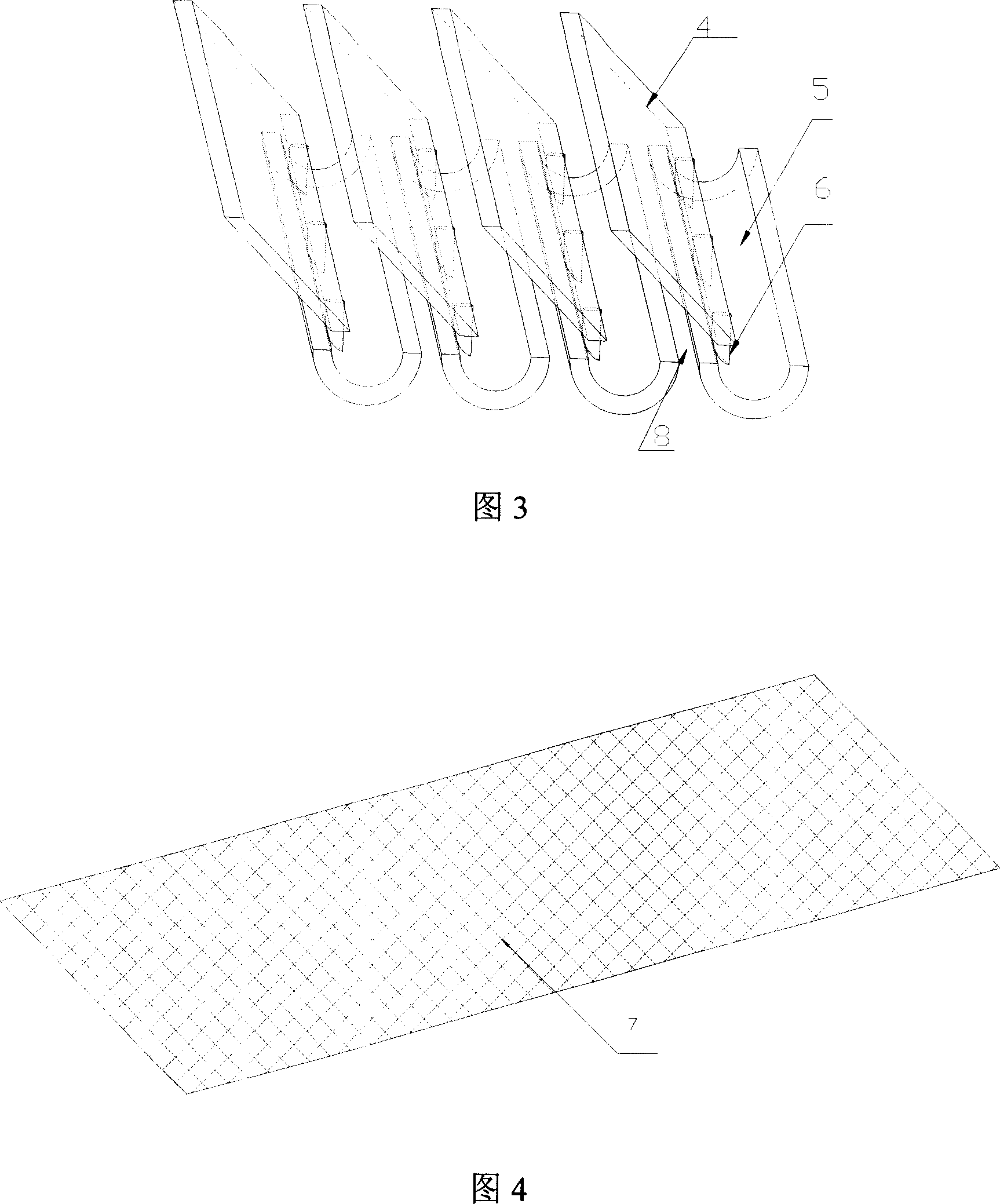

[0035] As shown in Figures 1, 2, 3, and 4, the 100-kilowatt roof-mounted bus fuel cell engine is designed to be ventilated, dust-proof and rain-proof. In this design, the fuel cell engine 3 is installed on the top of the bus. The louver blade 4 is provided with a dust-proof net 7, and the car shell on both sides beside the louver is provided with several vents 2, and the vent is provided with a dust-proof net 7, and the opening direction of the vent points to the bus rear. The louvers include multiple groups of single leaves, which are composed of blades 4 and grooves 5 connected thereto under the blades, and narrow and long gaps 8 are provided between the grooves. The blades of the louvers form an acute angle with the direction of the front of the bus, and are arranged in the shape of a car traveling against the wind. The blades of the shutters are fixed on the grooves connected thereunder by several screws 6 . For the single leaf of the louver, the rear single leaf blade is...

Embodiment 2

[0037] Referring to 1, 2, 3, and 4, the ventilation, dust, and rain-proof design of the 100 kW roof-mounted fuel cell engine on the bus is designed. The fuel cell engine is installed on the top of the bus. The car shells on both sides are provided with several air vents, the air vents are provided with dust-proof nets, and the opening direction of the air vents points to the rear of the bus. The louvers include multiple groups of single leaves, which are composed of blades and recesses 5 connected thereto under the blades. There are narrow and long gaps between the grooves, and dust-proof nets are arranged under the grooves. The blades of the louvers form an acute angle with the direction of the front of the bus, and are arranged in the shape of a car traveling against the wind. The blades of the louvers are welded to the grooves connected to them under the blades. For the single leaf of the louver, the rear single leaf blade is inclined to the direction of the front of the v...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com