Method for reinforcing and modifying through steel truss bridge

A technology of steel truss and down-fitting, which is applied in the field of reinforcement and renovation of down-down steel truss bridges. It can solve the problems of difficult maintenance and repair, high material consumption, and large structural damage, so as to simplify the steps of reinforcement and renovation and shorten the construction period. , Simple and convenient construction

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

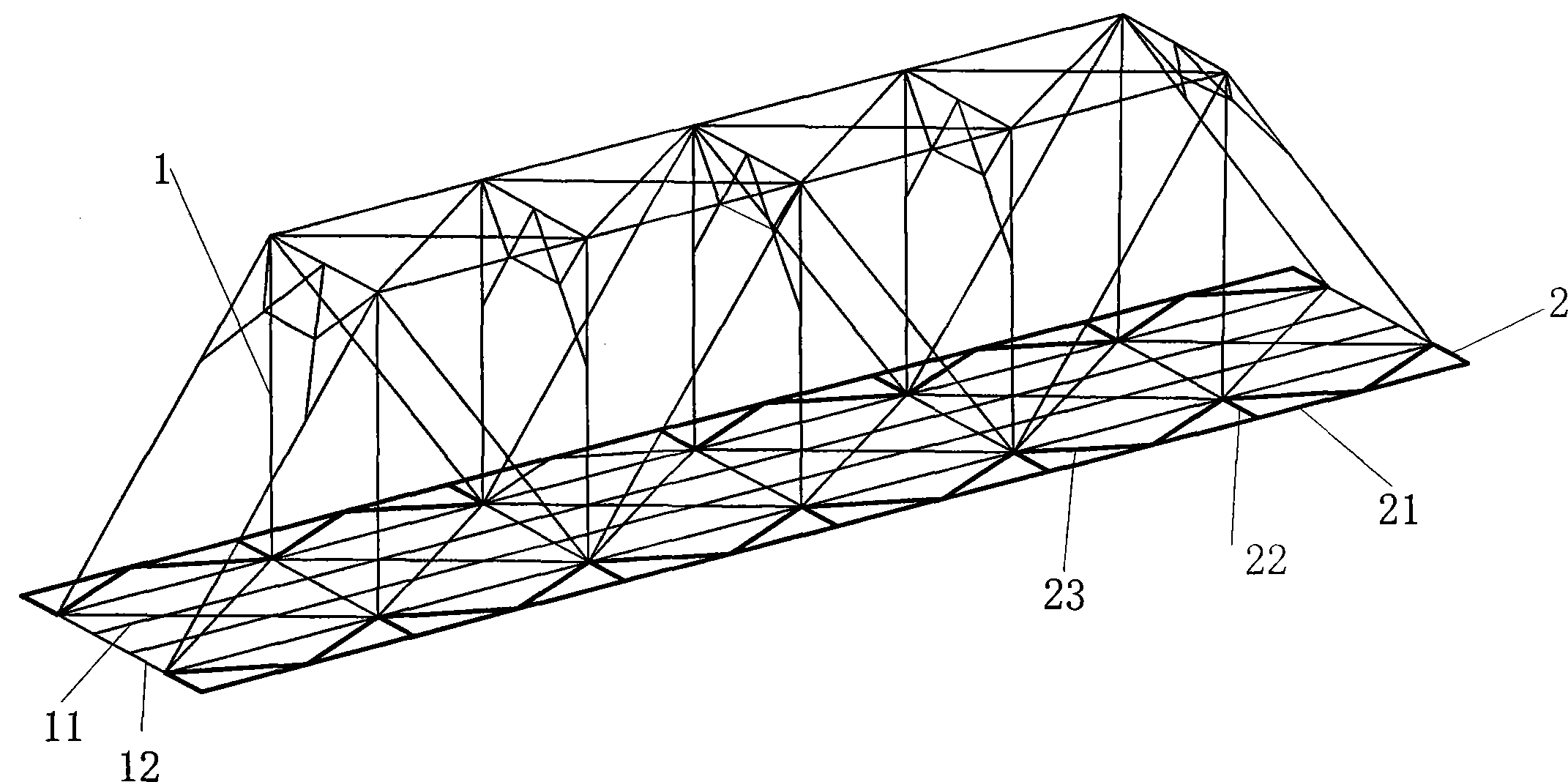

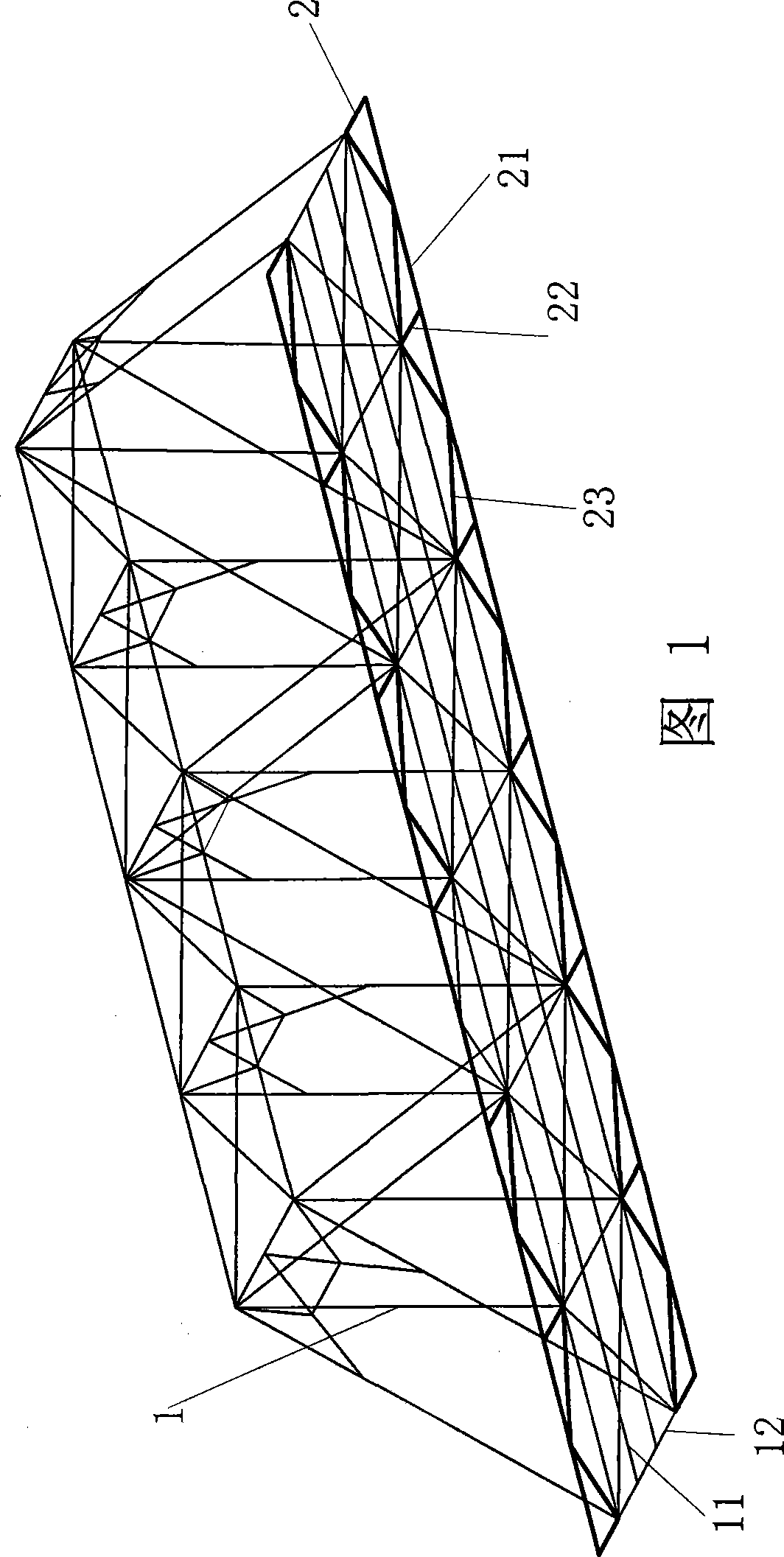

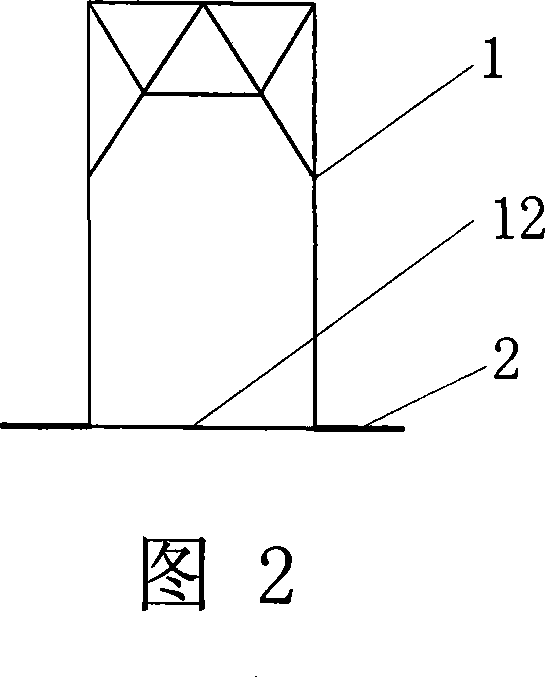

[0017] Figures 1 and 2 show that a specific embodiment of the present invention is: a method for strengthening and reforming a down-supported steel truss bridge, which is as follows: on both sides of the bottom of the truss 1 with a rectangular cross-section, welding or The way of threaded connection is fixedly connecting the plane bracket 2 of the steel structure, and the connected plane bracket 2 is on the same plane as the bottom of the truss 1 .

[0018] Wherein, the specific method of fixedly connecting the plane bracket 2 is: the end of the beam 12 at the bottom of the truss 1 protrudes and connects the cross brace 22; The diagonal braces 23 are obliquely connected in several rectangular internodes formed with the cross braces 22 ;

[0019] The specific method of obliquely connecting the diagonal braces 23 in the rectangular internodes is: connect one or more than one diagonal braces 23 in the rectangular internodes, and at least one end of one diagonal brace 23 is conne...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com