Fluid bed boiler for combusting biomass

A fluidized bed boiler, biomass technology, applied in the direction of fluidized bed combustion equipment, combustion method, combustion type, etc., can solve the problem of unable to maintain the fuel layer

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

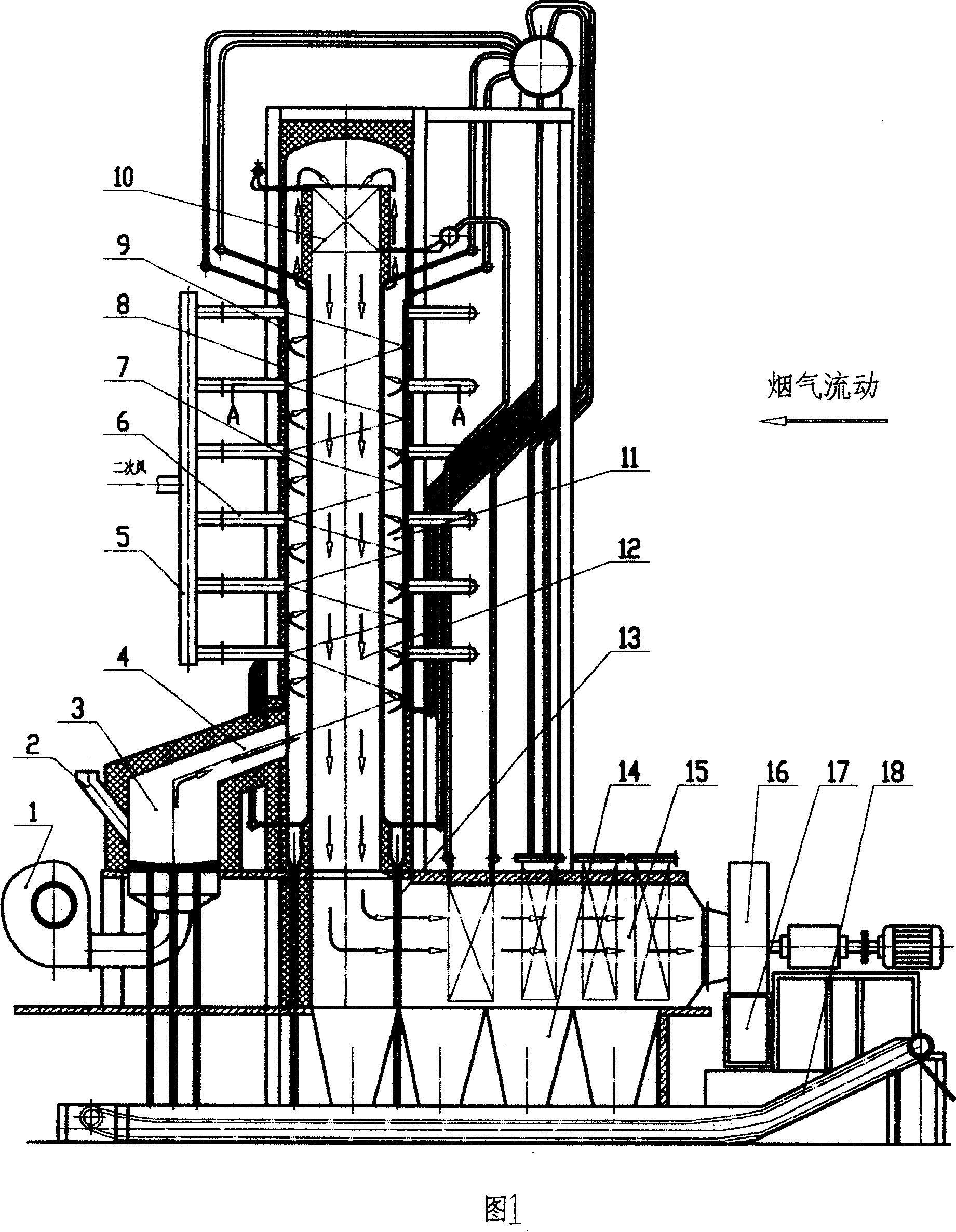

[0010] Below in conjunction with accompanying drawing, the present invention will be further described:

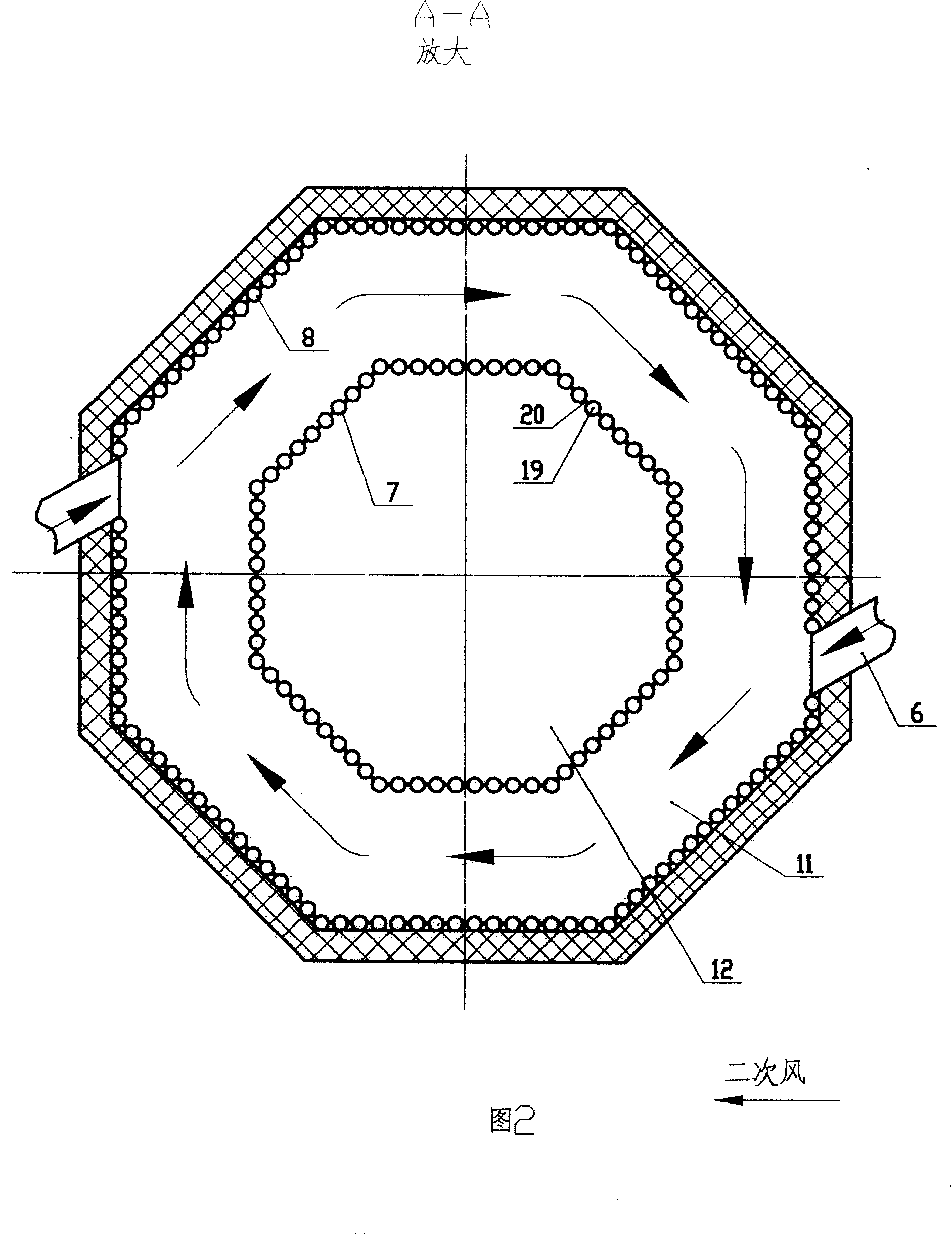

[0011] As shown in Figure 1: the invention mainly includes a fluidized bed boiler body, a blower 1, a feed hopper 2, a furnace 3, a furnace wall 9, a superheater 10, an ash drop pipe 13, an ash hopper 14, an induced draft fan 16, an outlet Smoke port 17, slag remover 18, membrane water-cooled wall tube 19, fins 20; the difference from the known fluidized bed boiler is that an independent high-temperature zone furnace 3 is set, and the biomass pellet fuel passes through the feed hopper 2 enters the furnace 3 in the high-temperature zone, and the biomass pellet fuel burns in the furnace 3 in the high-temperature zone, and the high-temperature flue gas produced enters the annular channel 11 through the transition zone 4 of the furnace under the action of the blower 1, as shown in Figure 2: the annular channel 11 It is formed by the gap formed between the inner cylinder 7 and ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com