Lateral motion reciprocating fire grate system

A horizontal movement and reciprocating technology, applied in the direction of mobile grates, furnace grates, incinerators, etc., can solve the problems of inconspicuous breaking up, no lateral movement, and insufficient combustion of garbage, etc., to achieve increased penetration effect, It is not easy to coke, and the effect of reducing the rate of heat loss

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0028] Further illustrate the present invention below in conjunction with accompanying drawing and embodiment:

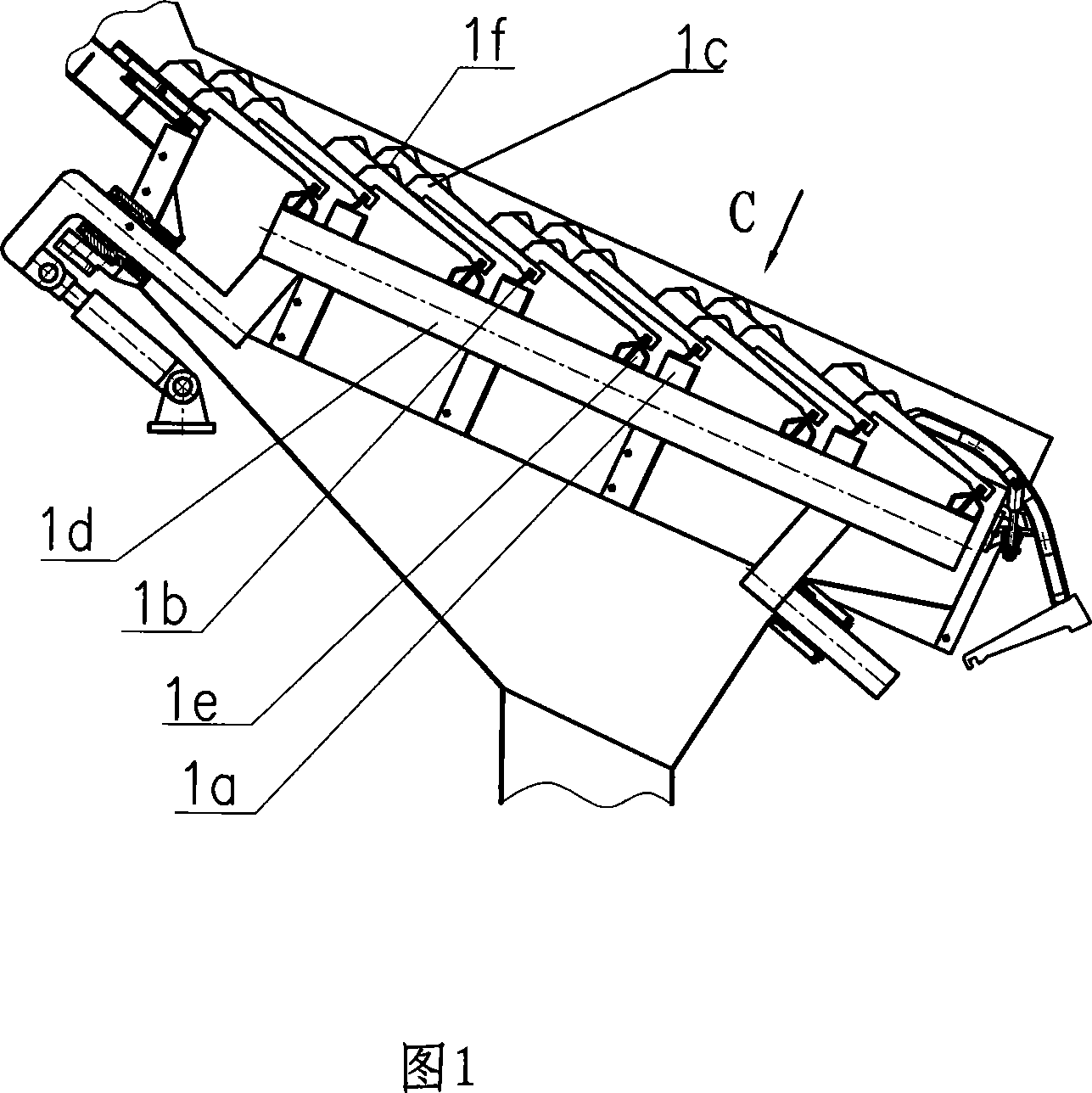

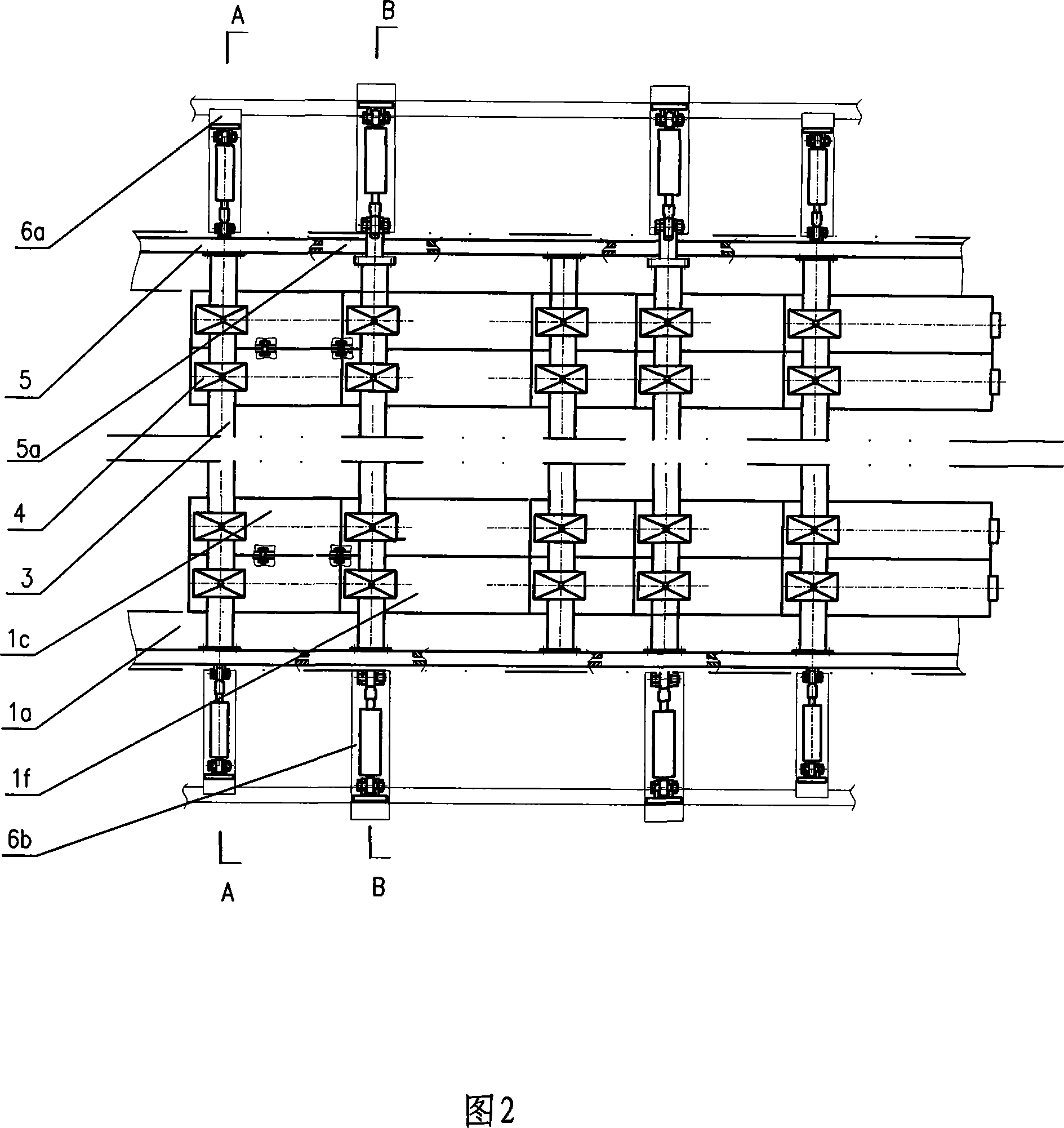

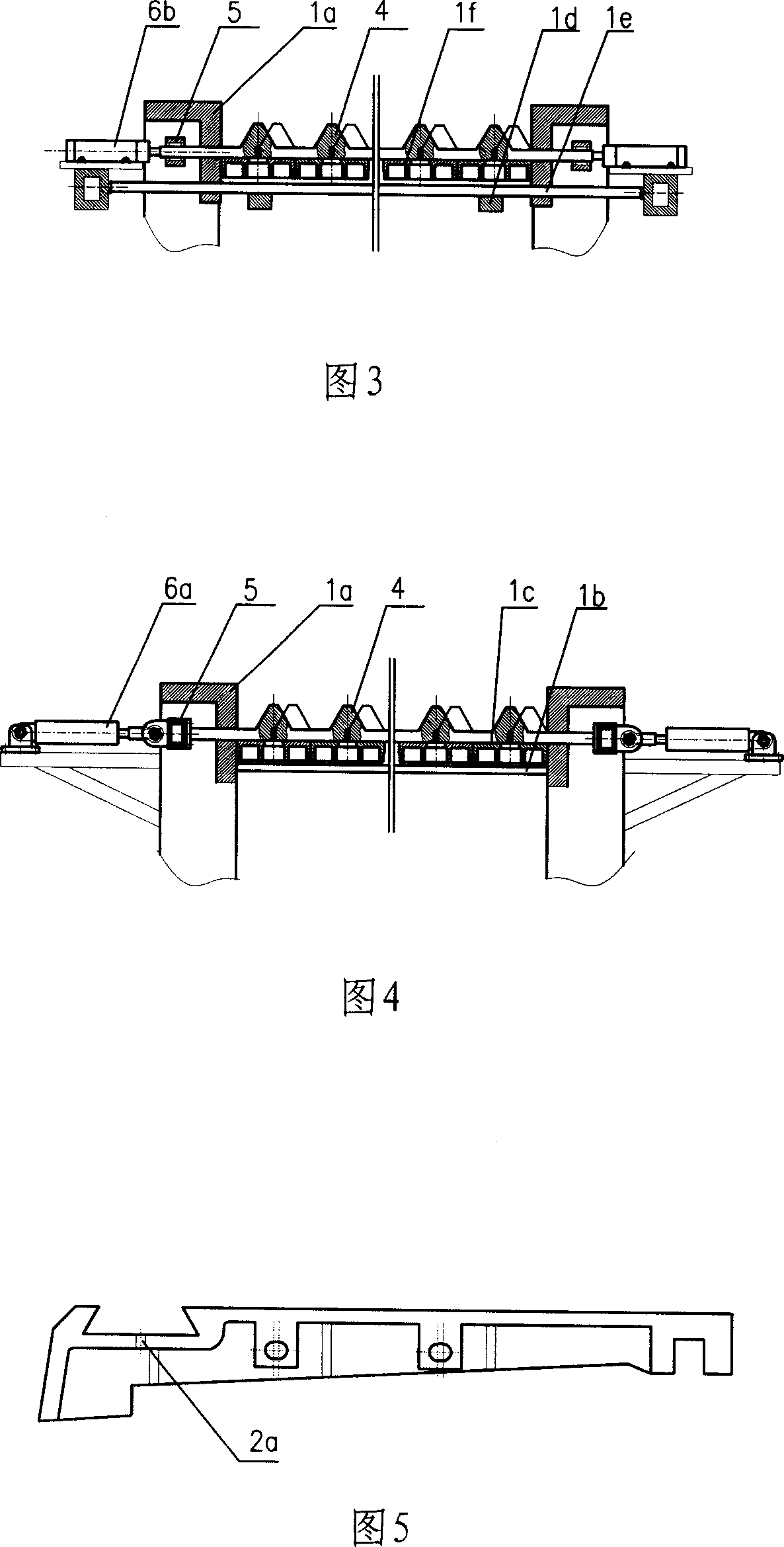

[0029] Please refer to Fig. 1, Fig. 2, Fig. 3, Fig. 4, Fig. 5, the present invention mainly consists of crossbeam 1a, pull bar 1d, push rod 5, fixed grate piece 1c, movable grate piece 1f, fixed oil cylinder 6a, movable oil cylinder 6b, connecting Composed of rod 3 and boss 4, the fixed grate plate 1c is formed by the fixed grate support 1b installed on the beam 1a passing through the fixed slot at the end of the same grate piece, and the movable grate plate 1f is formed by The movable grate support 1e on the movable grate pull rod 1d is formed through the slots at the end of the same row of movable grate pieces, and the fixed grate plate 1c and the movable grate plate 1f overlap front and back, and are arranged alternately to form a grate; The two ends of the beam 1a are fixed on the middle beam 1g, wherein, the head of the grate piece is provided with a dovetail t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com