Open and close type torque sensor

A torque sensor, tension-type technology, applied in the field of torque sensors, can solve the problems of poor reliability, easy wear of brush structure, low signal-to-noise ratio of signal transmission, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

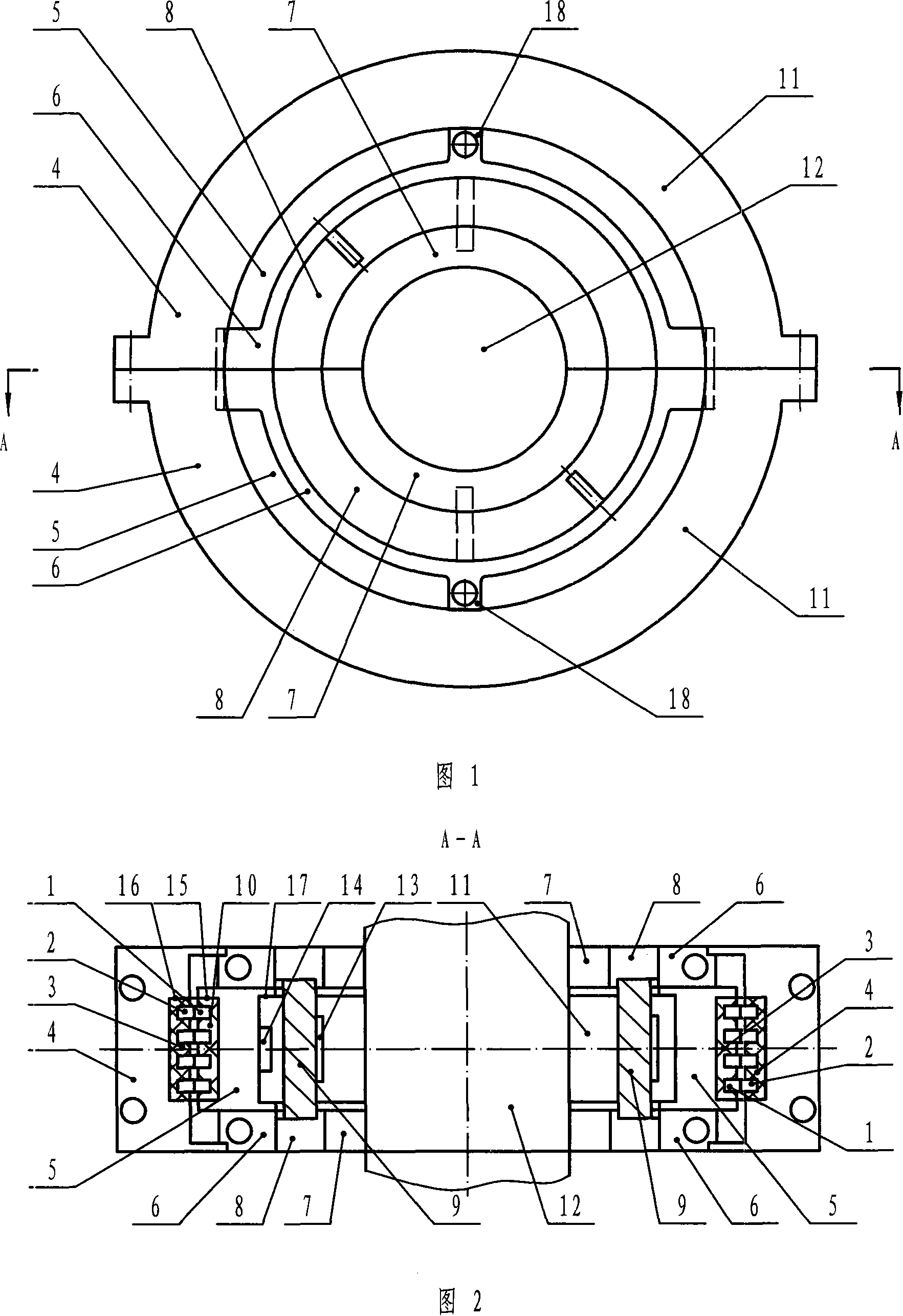

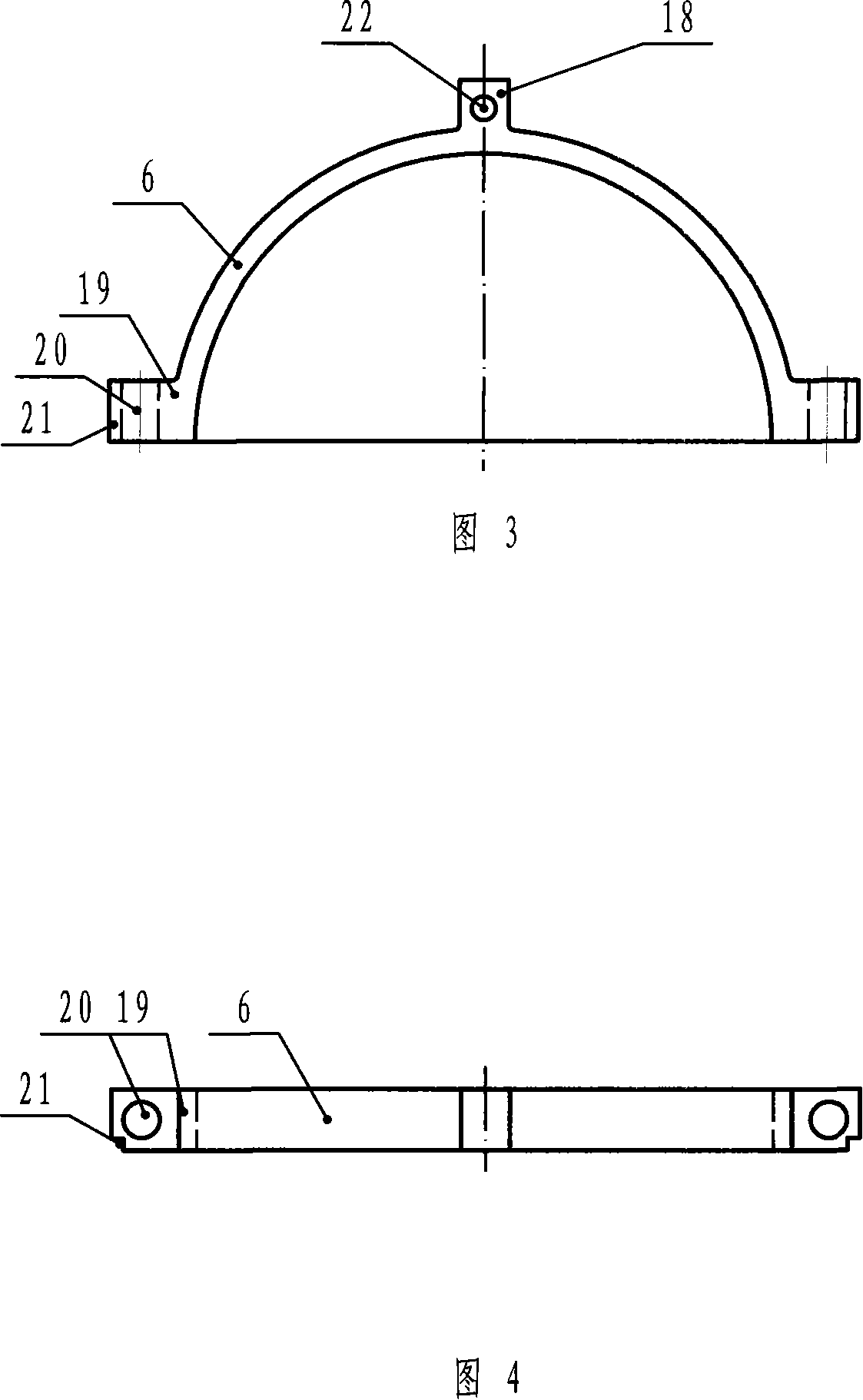

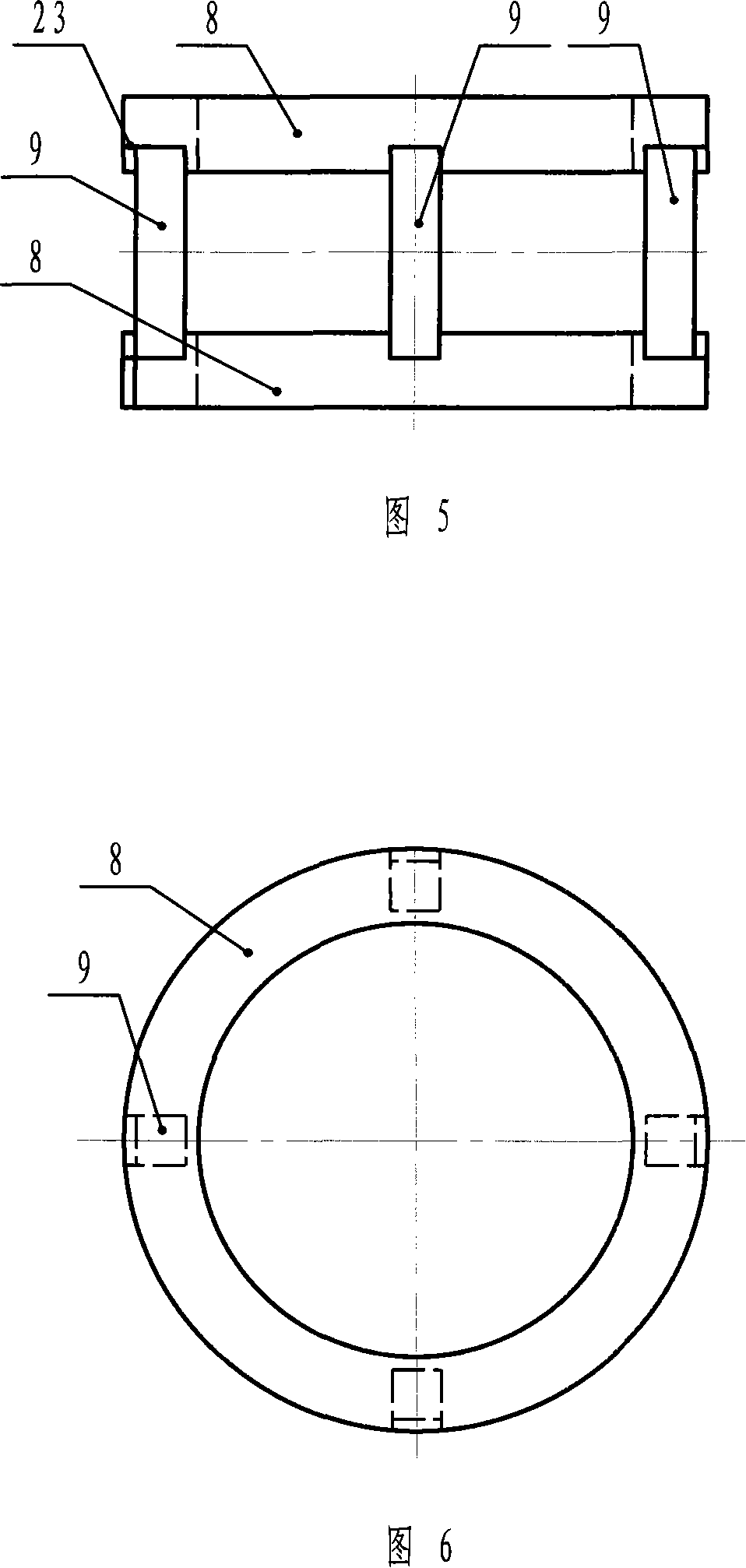

[0013] Fig. 1 is a schematic structural view of the tension sensor of the present invention, and Fig. 2 is an A-A sectional view of the tension sensor described in Fig. 1, the tension sensor of the present invention is symmetrically fixed by screws with two semicircular main bodies 11 having the same structure On the transmission shaft 12, the main body 11 mainly includes: a small conductive half ring 1, a large conductive half ring 2, a large insulating half ring 3, a small insulating half ring 10, an outer half shell 4, an inner half ring 5, a fastening half ring Ring 6, optional half-ring 7, connecting half-ring 8, sensitive beam 9, strain gauge 13 and amplification and conversion element 14, its structure is: the upper and lower end surfaces of the inner side of the outer half-shell 4 are fitted with fastening half-rings 6, tight The solid half ring 6 is fixed with the inner half ring 5 in the middle of the two tight half rings 6 through the boss 18, and the outer groove 15...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com