Chain used for diamond chain saw

A technology of diamond and diamond segment blocks, applied in stone processing tools, stone processing equipment, manufacturing tools, etc., can solve the problems of chain lengthening, loose link connection, de-chaining, etc., so as to improve sharpness and avoid edge collapse. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

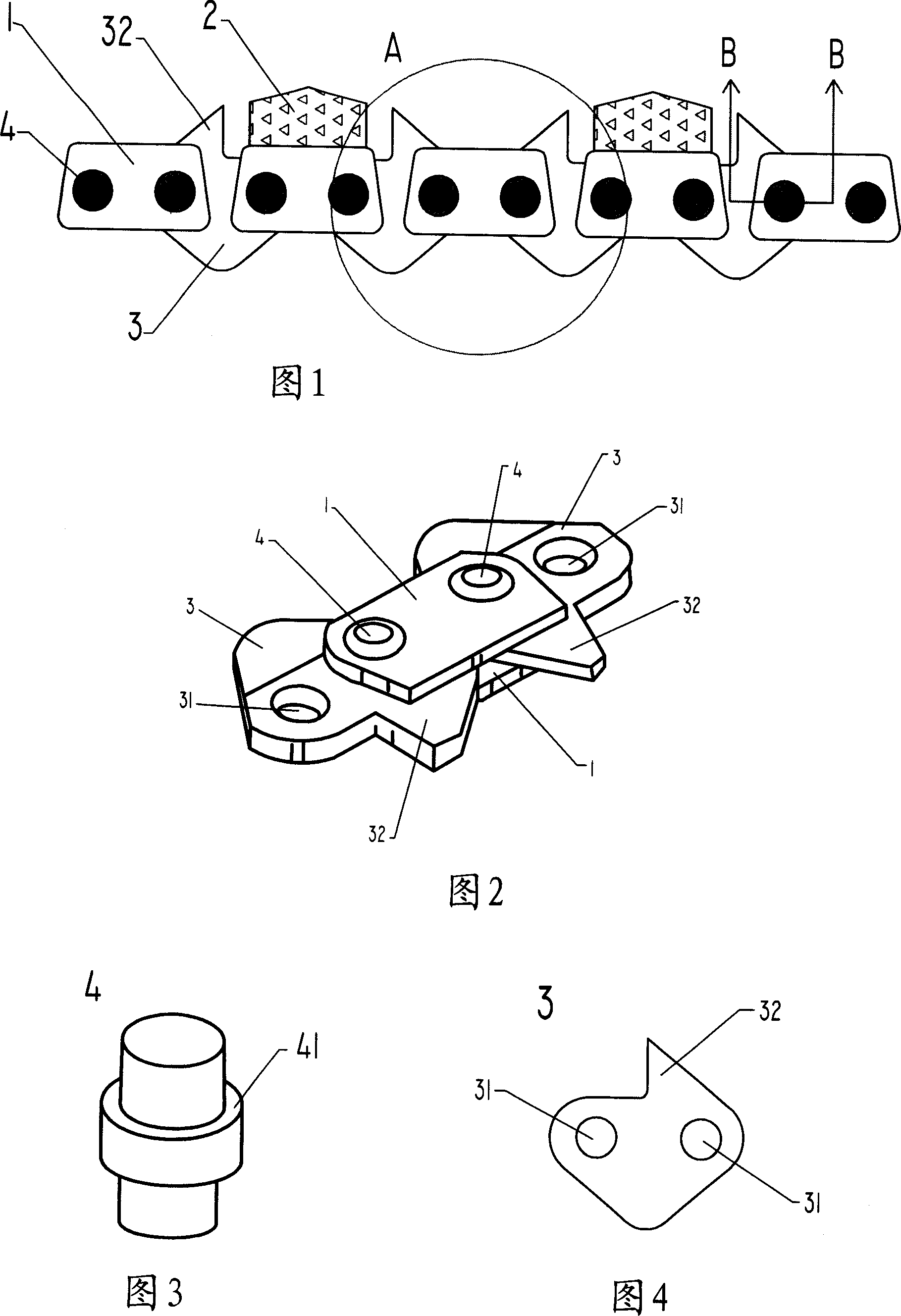

[0020] As shown in Figures 1 to 7, Embodiment 1 of the present invention is a chain with protective teeth, including a chain base 1, a diamond segment 2, a connecting piece 3 with protective teeth 32, a connecting shaft 4 and a rubber sealing washer. The material of the chain base 1, the connecting piece 3 and the connecting shaft 4 is high-strength alloy steel, and the diamond segment 2 is a diamond segment made by alloy powder pressing, brazing, electroplating and other processes. Connecting holes 31, the two ends of each chain substrate 1 are provided with substrate holes 11, the middle of the connecting shaft 4 is provided with a boss 41, the connecting hole 31 of the connecting piece 3 is sleeved on the boss 41 of the connecting shaft 4, and the connecting shaft 4 The two ends of the upper and lower chain bases are inserted into and riveted to the base hole 11 at the same end of the upper and lower chain bases 1, so that the two ends of the upper and lower chain bases 1 ar...

Embodiment 2

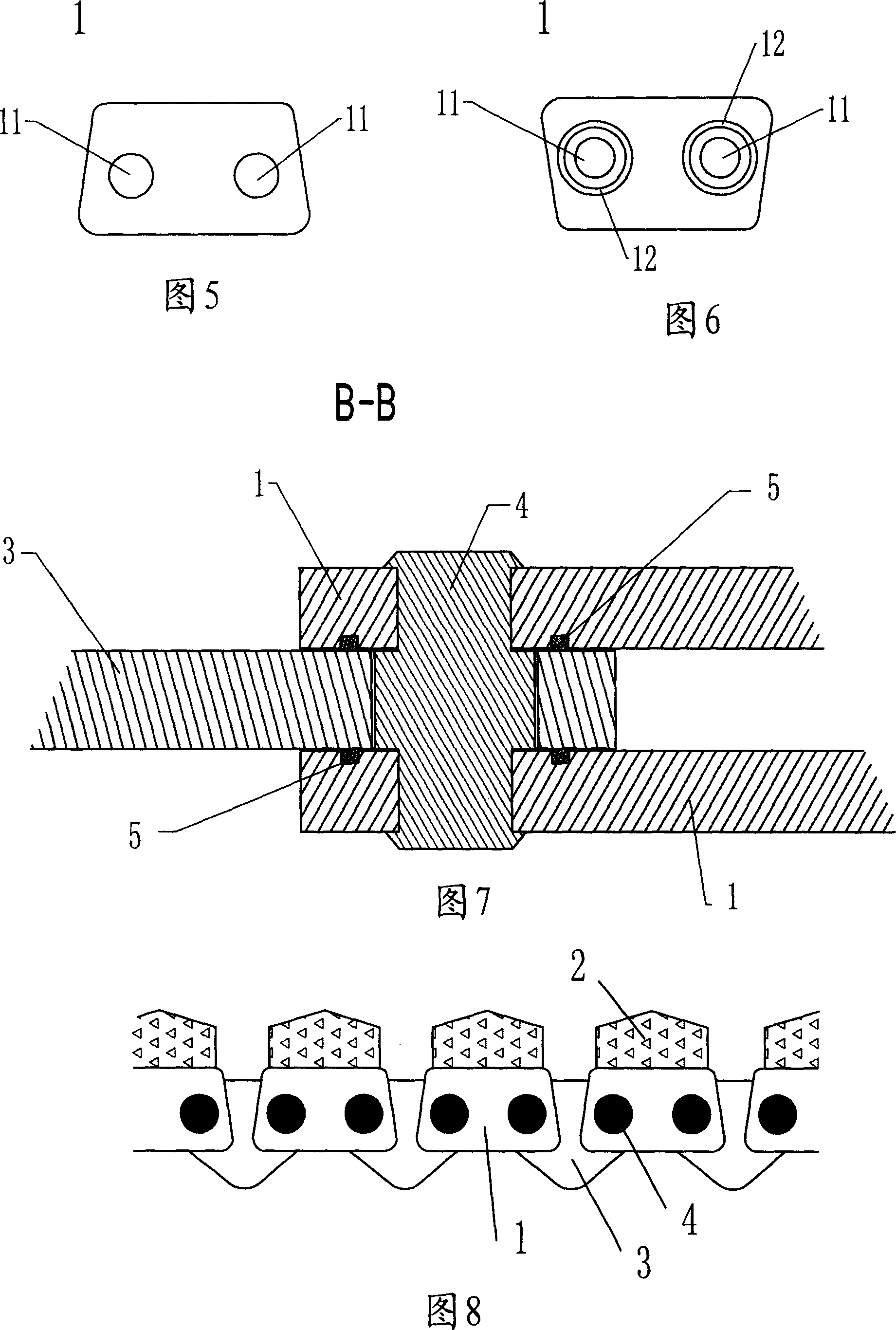

[0022] As shown in FIG. 8 , the second embodiment of the present invention is a chain without protective teeth, including a chain base 1 , a diamond segment 2 , a connecting piece 3 , a connecting shaft 4 and a rubber sealing washer. The diamond segment 2 is laser welded on each upper and lower chain substrate 1, and the connecting piece 3 is not provided with protective teeth. The rest are the same as in Embodiment 1, and will not be described here.

[0023] The materials of Embodiment 1 and Embodiment 2 of the present invention are high-strength alloy steel, which is wear-resistant and not easy to elongate. In addition, a sealing washer for the connecting shaft is provided between the connecting piece and the base body of the upper and lower chains. When the existing chain saw cuts strong abrasive materials such as stone and concrete, the mud and sand generated easily enter the connecting parts of the chain links. Loosening, the chain becomes longer, causing detachment or b...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com