Composite elevator cage and its producing method

A production method and composite technology, applied in the field of composite sills, can solve the problems of easy wear, unsightly, easy to rust, etc., and achieve the effects of strong wear resistance, high overall strength and simple production method.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

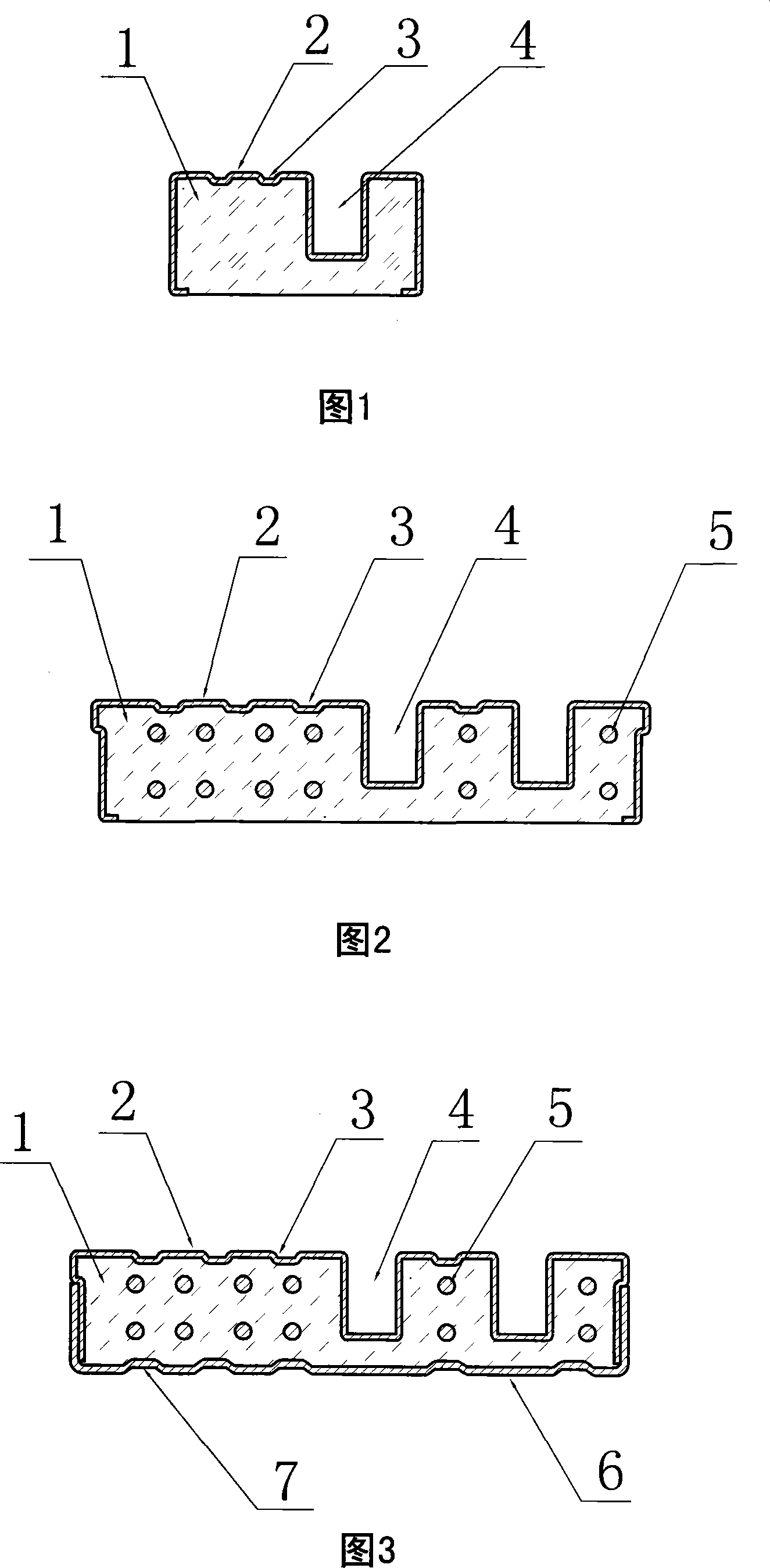

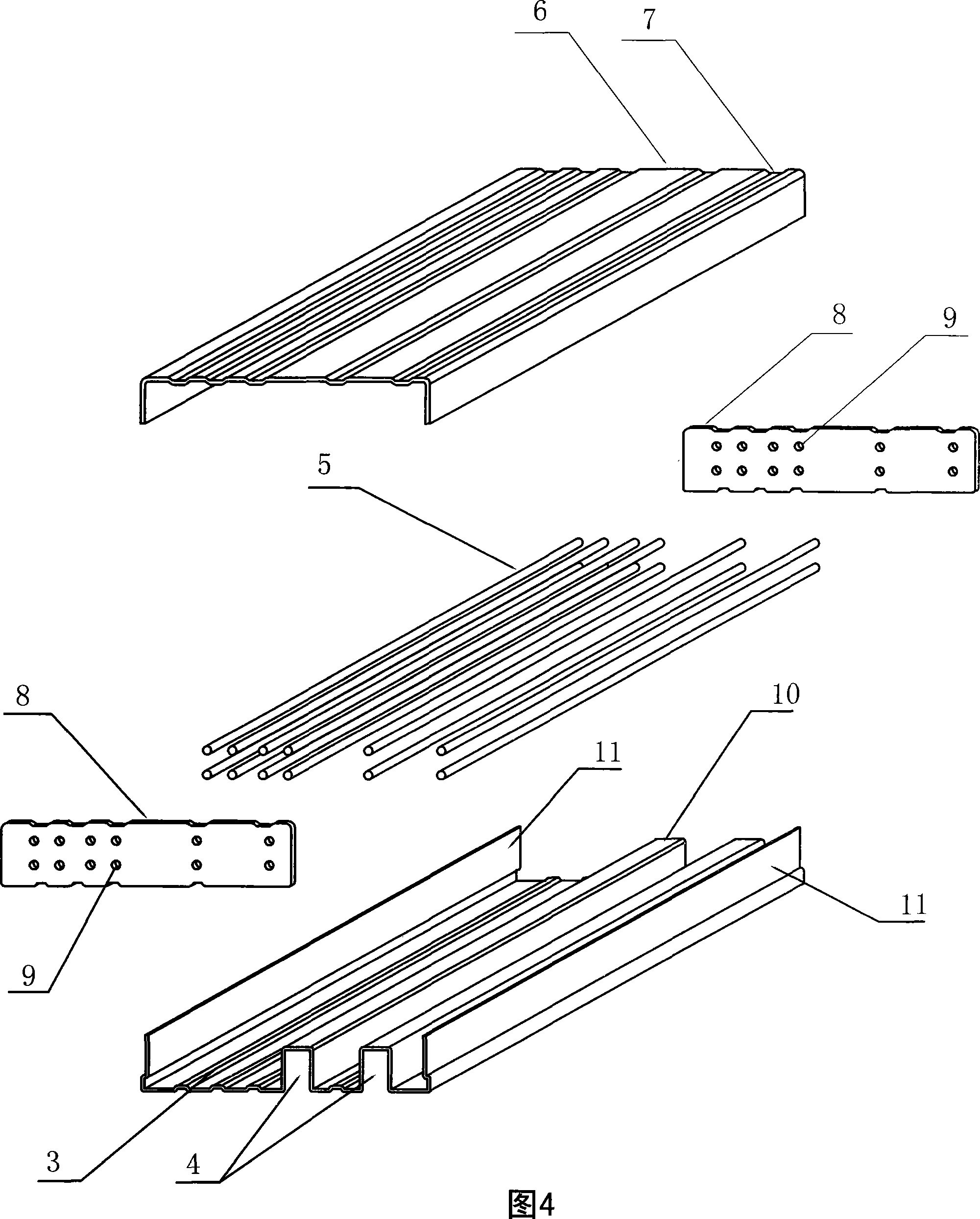

Embodiment 1

[0018] Example 1, a stainless steel and concrete composite elevator sill with a single elevator door chute, the sheath plate 2 is composed of an upper panel 10 and two end cover panels 8, and the upper panel 10 is rolled by a wear-resistant stainless steel plate Both sides of the longitudinal direction are provided with folded edges 11 that are bent vertically downwards and then horizontally bent inwards, and a grooved plate with a single elevator door chute 4 is formed in the middle, and the upper plane of the grooved upper panel 10 is also rolled There are anti-slip grooves 3; the end cover plates 8 located at both ends of the trough-shaped upper panel 10 are made of ordinary steel plates and fixed by welding; the base body 1 is poured with concrete into the cavity formed by the upper panel 10 and the two end panels 8 to solidify and form. Its specific production method is as follows:

[0019] ①, using a stainless steel plate to roll into a groove-shaped upper panel 10 with ...

Embodiment 2

[0023] Example 2, a stainless steel and reinforced concrete composite elevator sill with double elevator door chutes, the sheath plate 2 is composed of an upper panel 10 and two end cover panels 8, and the upper panel 10 is rolled by wear-resistant stainless steel plate Both sides of the longitudinal direction are provided with folded edges 11 that are bent vertically downwards and then horizontally bent inwards, and a grooved plate with double elevator door chutes 4 is formed in the middle, and the upper plane of the grooved upper panel 10 is also rolled There are anti-skid grooves 3; the end cover plates 8 located at both ends of the groove-shaped upper panel 10 are made of ordinary steel plates or plastic plates, and a number of steel positioning holes 9 are opened on the plate surface; the base body 1 is poured with concrete on the upper panel 10 and the two end panels Solidify and form in the cavity of the built-in steel bar formed by 8 walls. Its specific production meth...

Embodiment 3

[0028] Example 3, the stainless steel and reinforced concrete composite fully-covered elevator sill with double elevator door chutes, the sheath plate 2 is composed of an upper panel 10, two end cover panels 8 and a bottom panel 6, and the upper panel 10 is made of The wear-resistant stainless steel plate is rolled into a groove-shaped plate with downwardly bent vertical folds 11 on both sides of the longitudinal direction, and a groove-shaped plate with double elevator door chutes 4 in the middle. The upper plane of the groove-shaped upper panel 10 is also rolled There are anti-skid grooves 3; the end cover plates 8 located at both ends of the trough-shaped upper panel 10 are made of ordinary steel plates or plastic plates, and a number of steel positioning holes 9 are provided on the plate surface; the bottom plate 6 is made of ordinary steel plates or plastic plates. The bottom of 10 and the two sides of the trough-shaped plate coincide with each other, and the bottom plate ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com