Method for manufacturing stainless steel elevator sill

A production method, stainless steel technology, applied to elevators in buildings, transportation and packaging, etc., can solve the problems of door opening and closing obstacles, inability to mass produce, weak resistance, etc., achieve high straightness and parallelism, and facilitate The effect of mass production and low production cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

[0033] A method for manufacturing a stainless steel elevator sill, comprising the following steps:

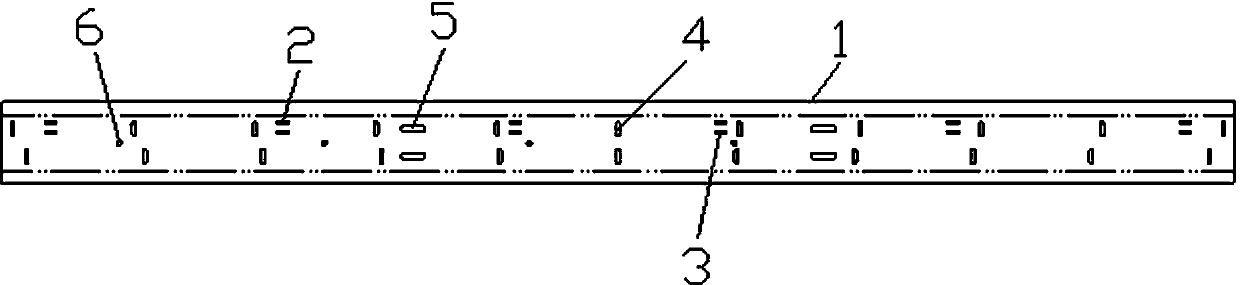

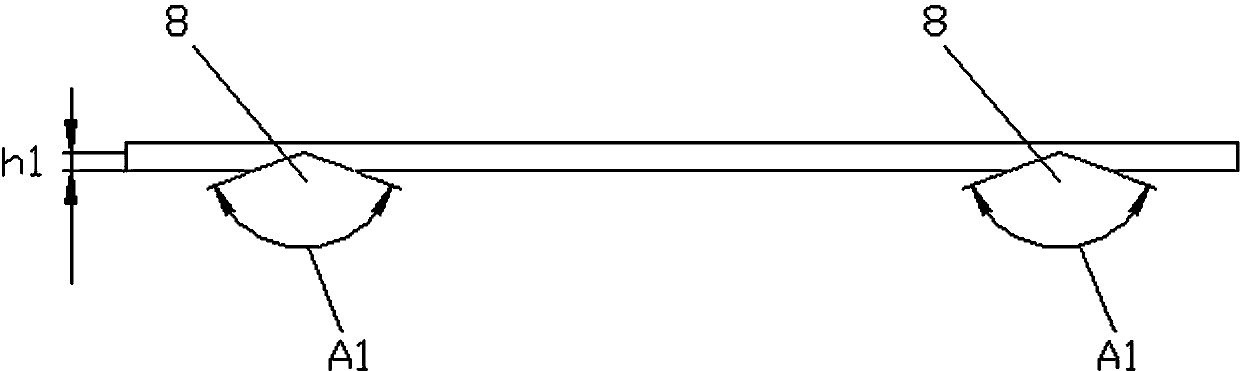

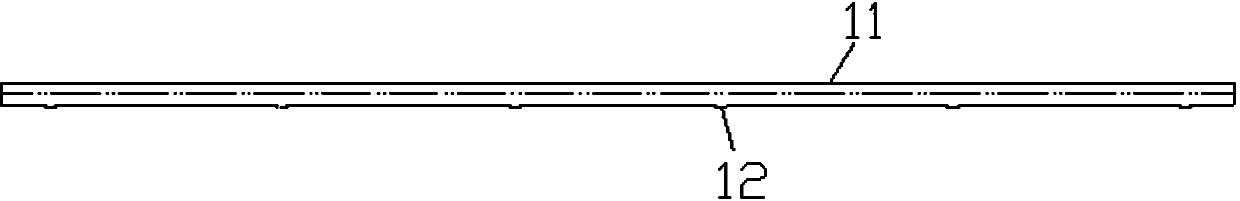

[0034](1) Cut the stainless steel plate with a thickness of 3mm into five strips according to the required size, including the first strip 1, the second strip 11, the third strip 15, and the fourth strip 18 , the fifth strip plate 24, the longitudinal one side of the second strip plate 11 is formed with the first projection 12, the longitudinal side of the fourth strip plate 18 is formed with the second projection 19, then on the first strip The first positioning hole 2, the second positioning hole 3, the welding hole 4, the chip removal hole 5, and the through hole 6 are opened on the plate 1, and the through hole 6 is uniformly formed along the longitudinal centerline on the first elongated plate 1 by laser. Set at intervals, put the pressure riveting screws 7 into the through holes 6, and press the heads of the pressure riveting screws 7 into the through holes 6 by using riv...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| length | aaaaa | aaaaa |

| length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com