Cloth bag grouting pile-forming method

A bagging and grouting technology, which is applied to sheet pile walls, buildings, and foundation structure engineering, can solve the problems of difficult penetration of hard layers and limited reinforcement depth, and achieve the effects of controlling investment, high strength, and solving settlement stability problems

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

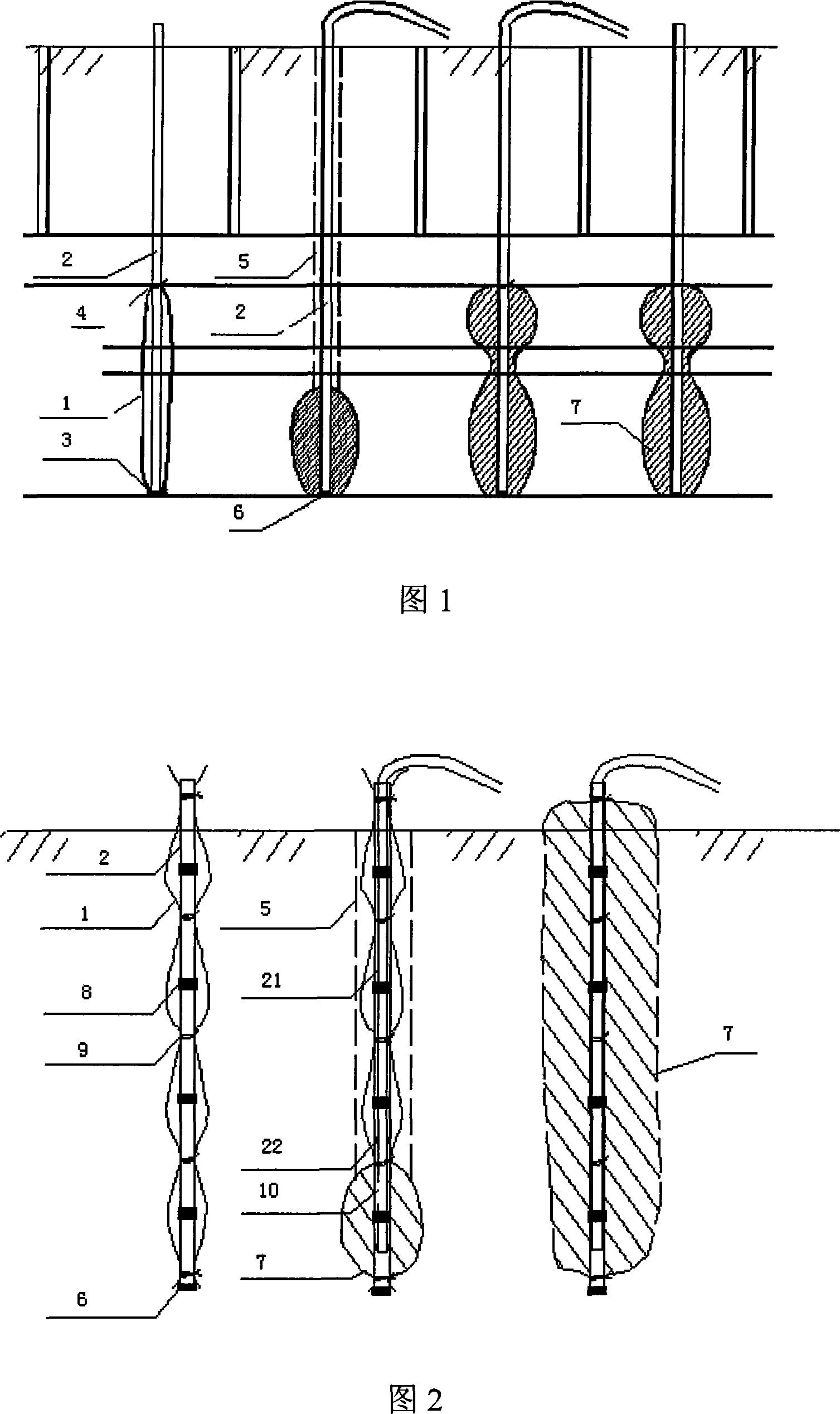

[0027] Embodiment 1: Refer to Fig. 1, Fig. 1 shows the formation process of deep-buried cloth bag piles in interbedded soft soil.

[0028] The method of the present embodiment comprises the following steps:

[0029] 1) Form the pile hole 5 in the soil layer with a hole-forming machine. The hole-forming machine adopts ordinary geological drilling rig, rotary drilling rig or vibrating pipe sinking machine, and wall protection mud can be properly configured according to needs. When using a drilling rig to form a hole, the diameter of the hole is ≥ 91mm, and the clear water circulation is generally used during drilling. For the stratum that is prone to collapse, mud circulation is used instead. When the vibrating pipe sinking machine is used to form the hole, the hole diameter is generally greater than 100mm, so as to ensure that the bagged grouting pipe can be placed through the sinking pipe; when constructing super long piles, the collar type sinking pipe construction can be us...

Embodiment 2

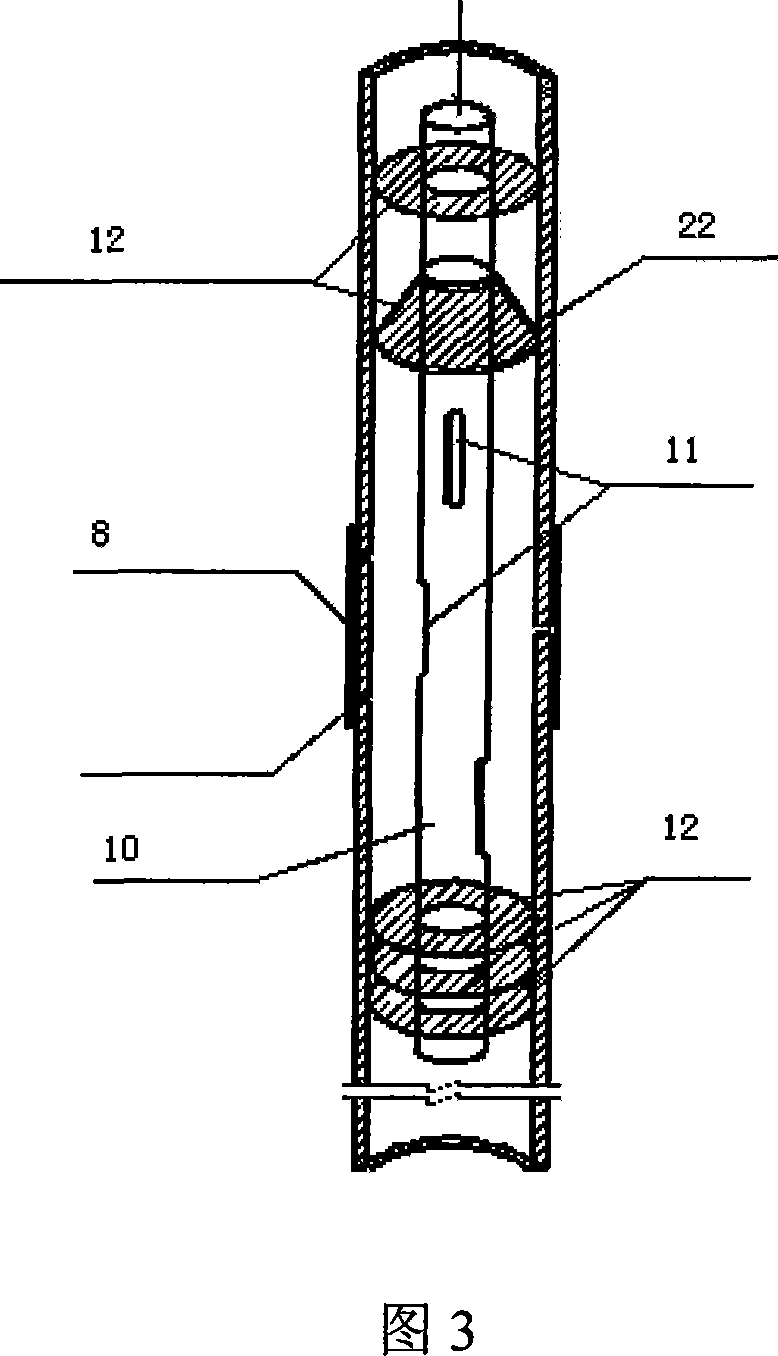

[0033] Embodiment 2: Refer to Fig. 2, which shows the formation process of shallow buried cloth bag piles in homogeneous soft soil.

[0034] The method of this embodiment is basically the same as that of Embodiment 1, the difference is that in the step 2, the grouting pipe is composed of a grouting pipe body 21, a guide pipe 22 and a grouting gun head, and in the guide pipe 22 pipe walls are provided with grouting holes along the axial section. The grouting gun head includes a short pipe 10 whose outer diameter is smaller than the inner diameter of the guide pipe 22. The short pipe 10 is inserted into the guide pipe 22. The pipe wall of the pipe 10 is provided with a gun head grouting hole 11, and the short pipe wall on both sides of the gun head grouting hole 11 is provided with a grout stop piston 12 that seals between the guide pipe 22 and the short pipe 10, The lower end of the short pipe 10 is closed, and the upper end is connected with the grouting pipe body 21 . Put th...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Area | aaaaa | aaaaa |

| Bursting strength | aaaaa | aaaaa |

| Aperture | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com