Partition block type sticking-free flection-proof steel plate shearing force wall

A technology of steel plate shear wall and block division, which is applied in the direction of walls, earthquake resistance, building components, etc., can solve the problems of easy cracking, difficult installation, large wall area, etc., and achieve simple fabrication and construction, easy fabrication and installation, and seismic performance Good results

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

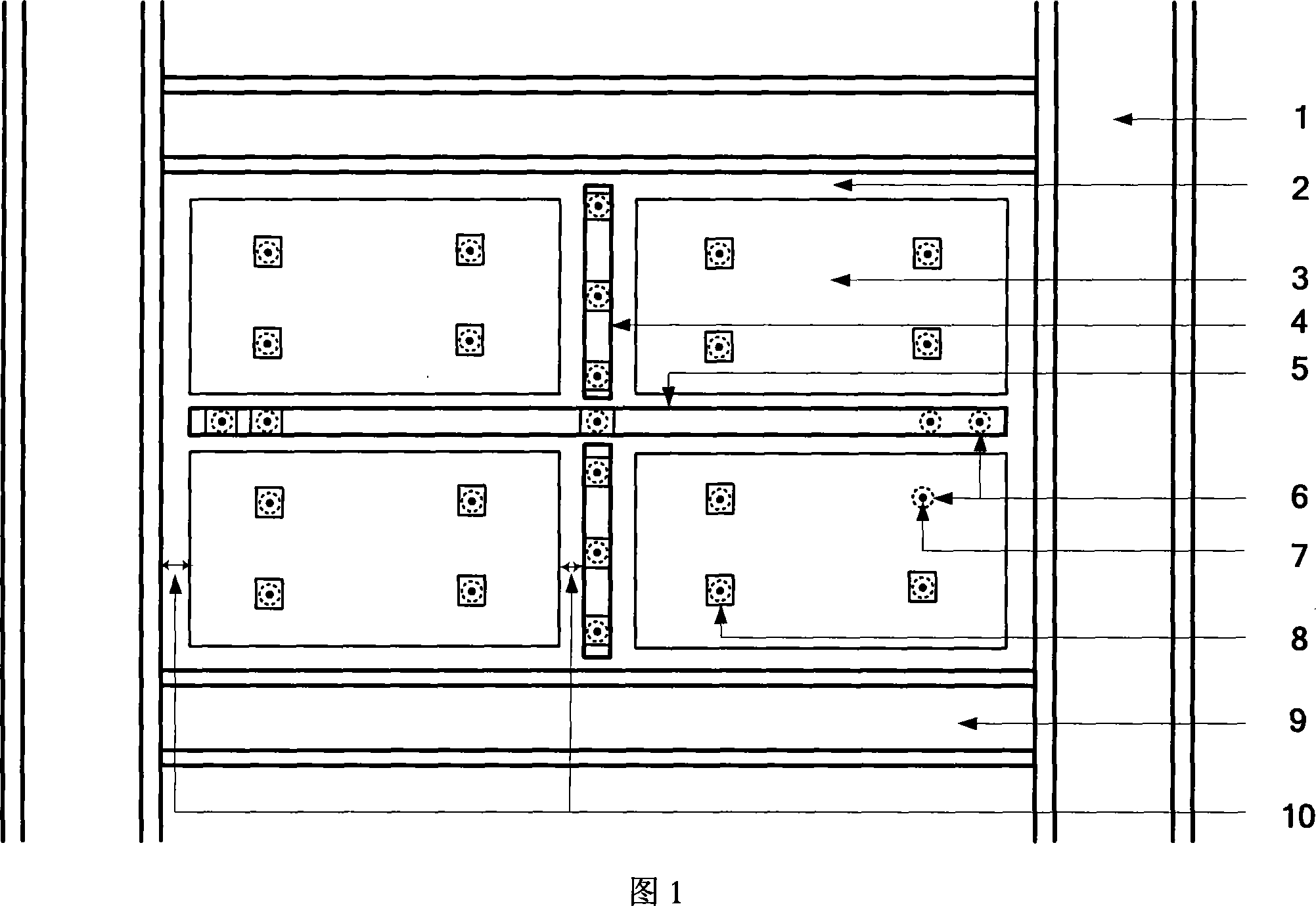

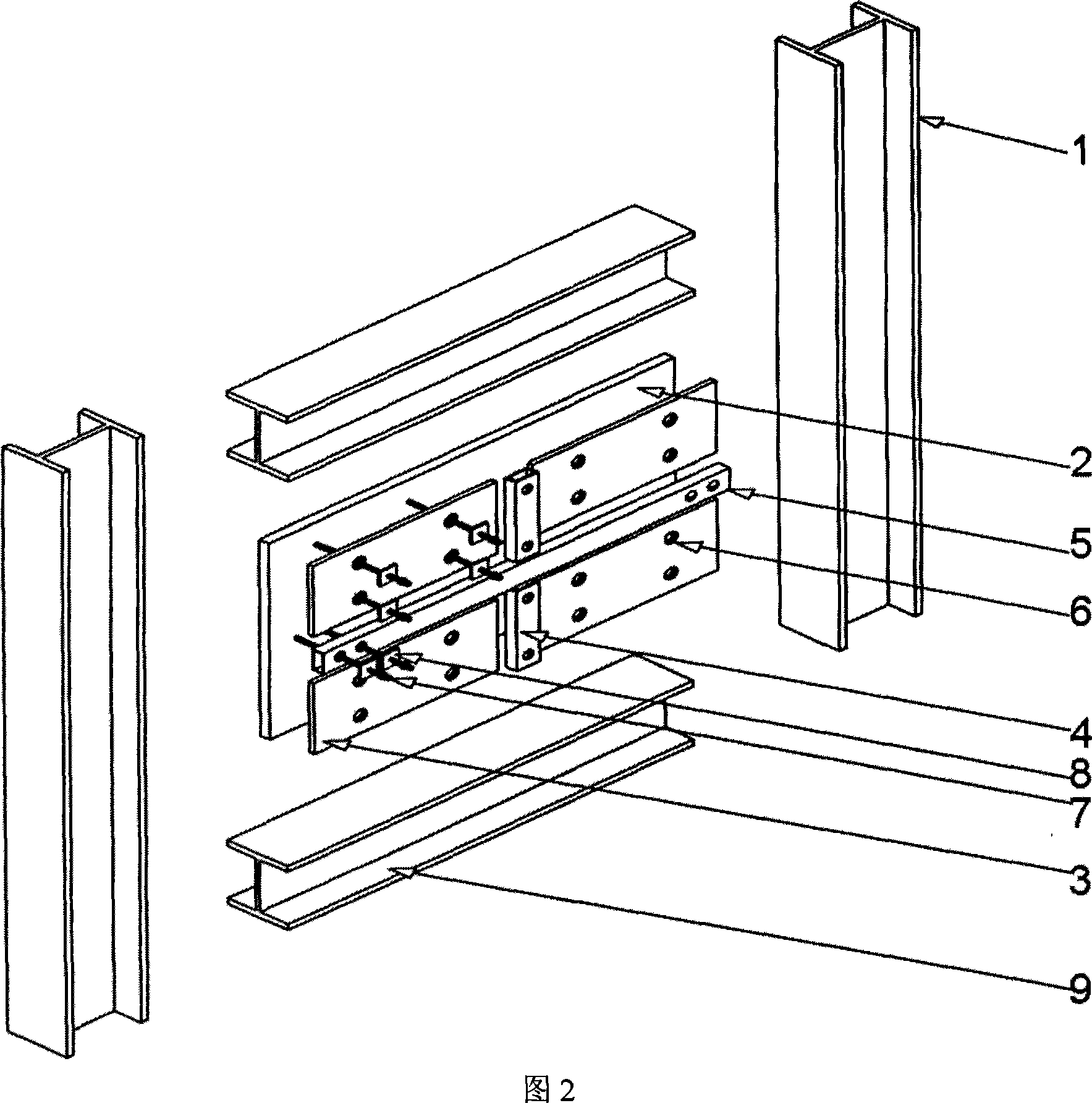

[0019] The technical scheme of the present invention is described in detail below in conjunction with accompanying drawing:

[0020] As shown in Figure 1-2,

[0021] 1- edge column

[0022] 2- Embedded steel plate

[0023] 3-Peripheral partition concrete cover

[0024] 4- Peripheral vertical steel stiffeners

[0025] 5- Peripheral transverse steel stiffeners

[0026] 6-The large round hole reserved on the concrete cover plate and steel stiffener

[0027] 7-Connecting bolts between the embedded steel plate and the peripheral concrete cover plate and steel stiffener

[0028] 8-Steel spacer between nut and steel stiffener

[0029] 9 - Edge Beam

[0030] 10-The reserved gap between the peripheral restraint unit (concrete cover plate and steel stiffener) and the frame

[0031] The zoned unbonded anti-buckling steel plate wall of the present invention is composed of embedded steel plates, peripheral zoned concrete cover plates, peripheral steel stiffeners and edge members; t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com