Dryer

A dryer and drying technology, which is applied in the direction of drying solid materials, drying, drying machines, etc., can solve the problem of high processing cost, achieve high drying efficiency, stable product quality, and good drying effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0018] In order to better illustrate the present invention, the implementation and characteristics of the present invention will be further introduced below through specific examples, but it should not be construed as limiting the scope of implementation of the present invention.

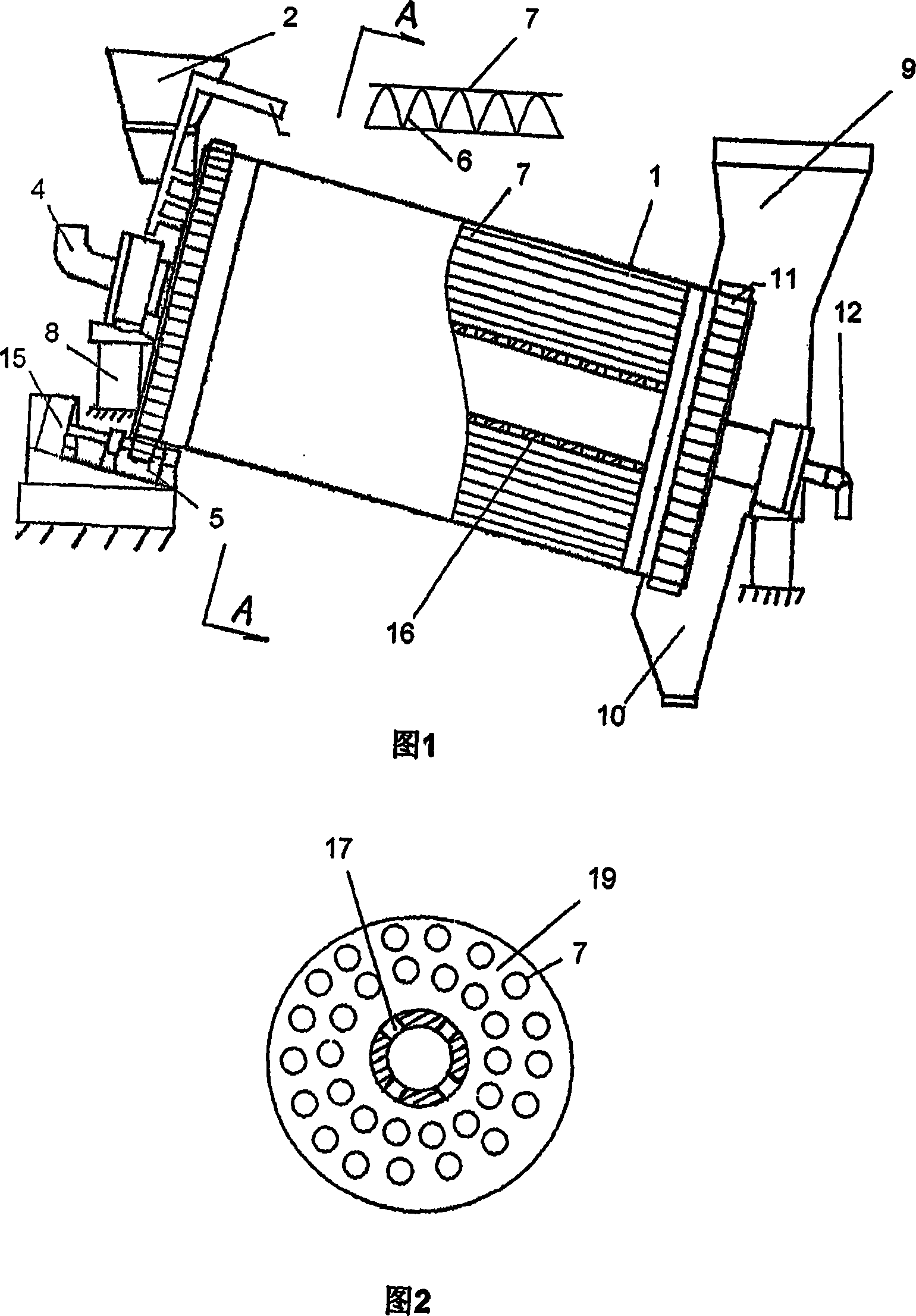

[0019] As shown in FIG. 1 , the tubular dryer of the present invention includes a dryer cylinder 1 , a supporting device 8 and a driving device 5 for the dryer cylinder. The driving device 5 meshes with the teeth 11 at the end of the dryer cylinder 1 and is used to drive the dryer cylinder 1 to rotate, so that the rotation speed of the tube dryer is usually kept at 5-10 rpm. The teeth 11 are arranged on the outer circumference of the dryer cylinder 1 . Fig. 1 only shows the driving device 5 located in the feed section. An additional driving device can be provided at the outlet end as required. Said drive means comprises a power element of, for example, a steplessly variable speed motor. The dryer...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Particle size | aaaaa | aaaaa |

| Particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com